Sectional exposure method of reel-to-reel maskless laser direct-writing photoetching device

A technology of laser direct writing and lithography equipment, which is applied in the direction of microlithography exposure equipment, photomechanical equipment, photo-plate making process exposure equipment, etc., and can solve the problem of exposure pattern height limitation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

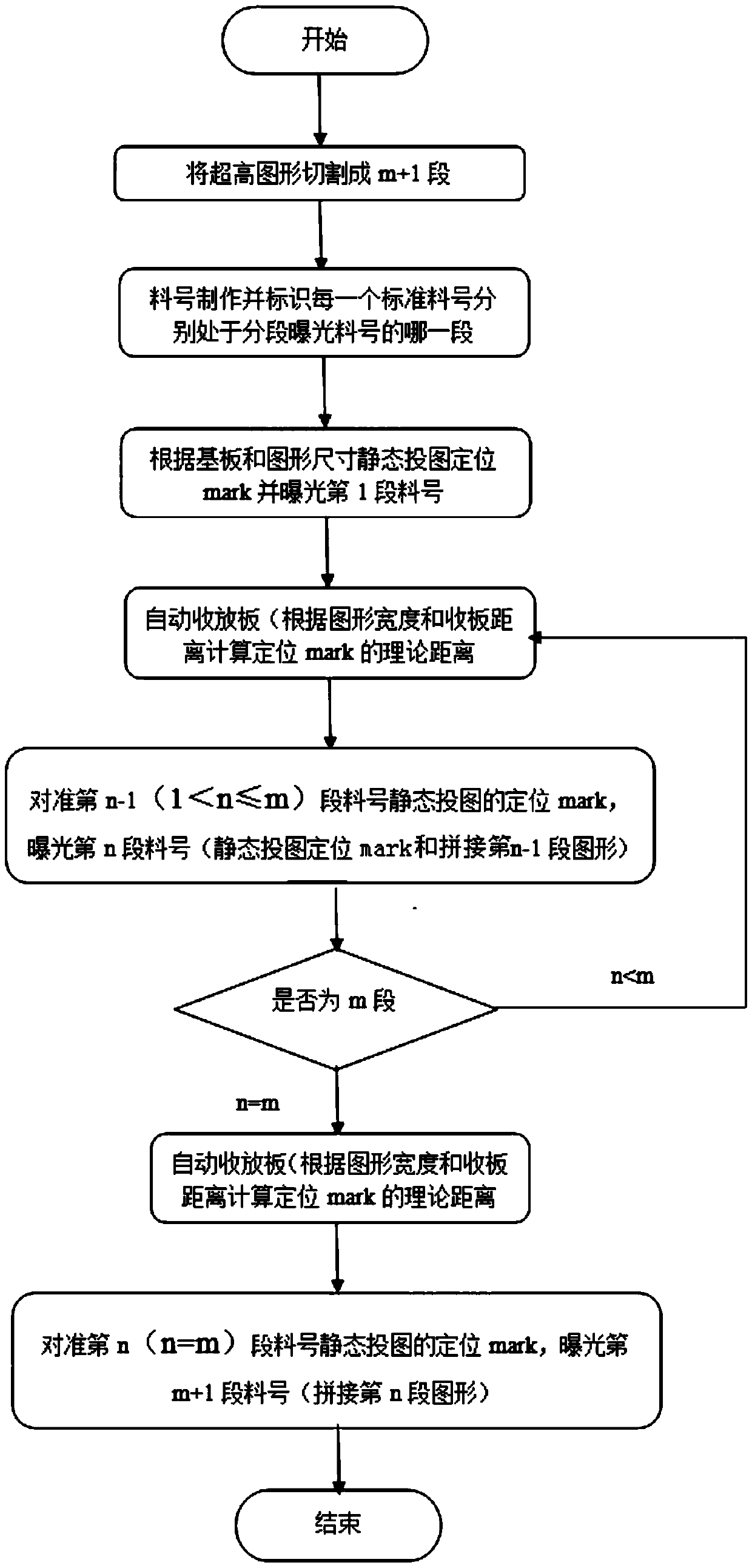

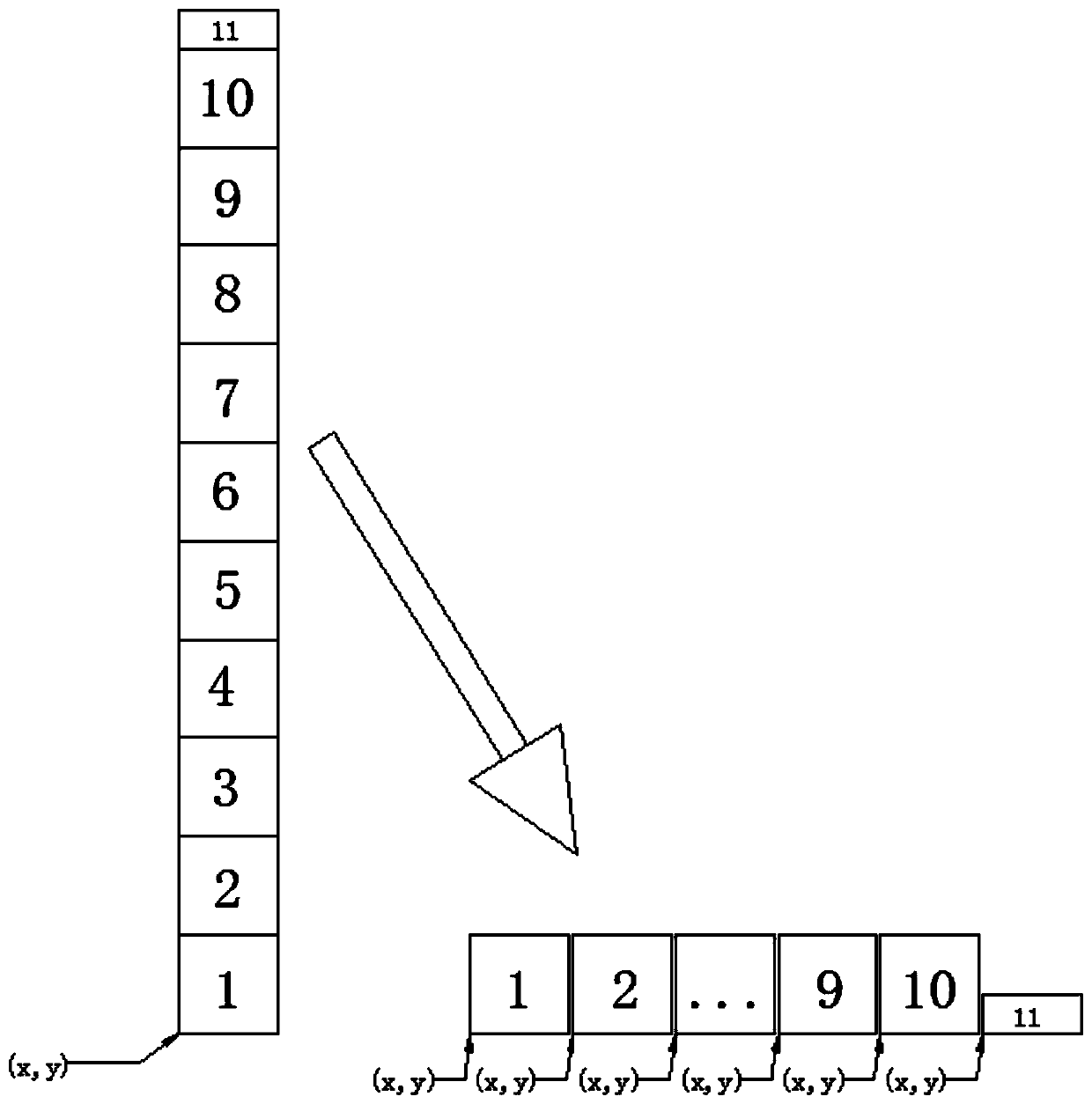

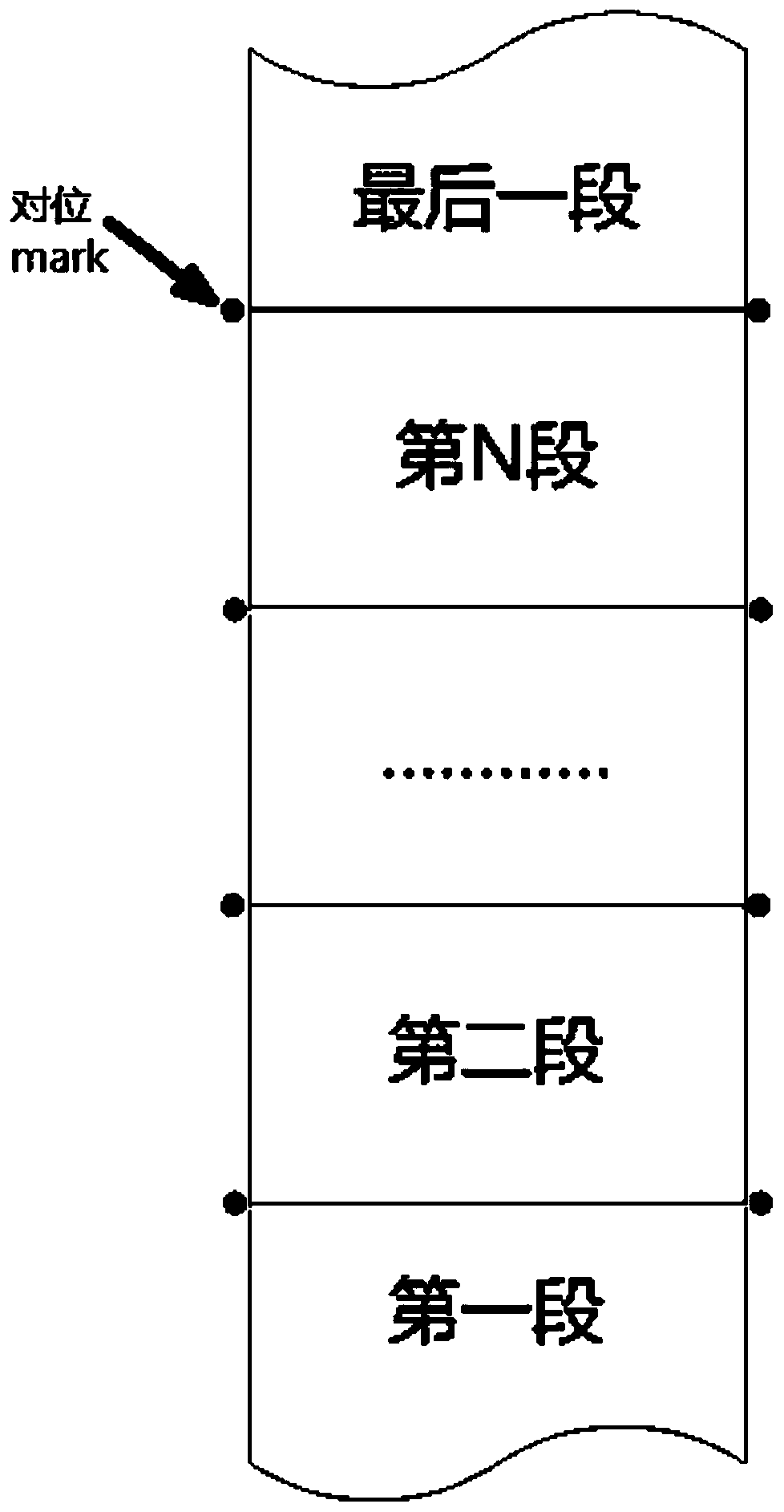

[0018] Such as Figure 1-Figure 2 Shown is a segmented exposure method for roll-to-roll maskless laser direct writing lithography equipment. This method is to cut the ultra-high pattern into several segments, and each segment of the graphic is used as an independent exposure graphic to make a material number. When there is a suitable alignment hole, it can be directly aligned for exposure. When there is no suitable alignment hole, the exposure of the second segment needs to expose two marks of the material number of the previous segment as the target of the alignment exposure of the latter segment until all segment splicing is completed. The part number of the last graphic does not need to expose two positioning marks. Specifically, the method includes the following steps:

[0019] (1) Cutting superelevation graphics: cutting the superelevation graphics to be exposed int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com