Diaphragm valve

一种隔膜阀、隔膜的技术,应用在隔膜阀、隔膜、阀细节等方向,能够解决半导体制造设备费增大、半导体制品制造成本恶化等问题,达到加工容易、流动容易稳定、加工作业性好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

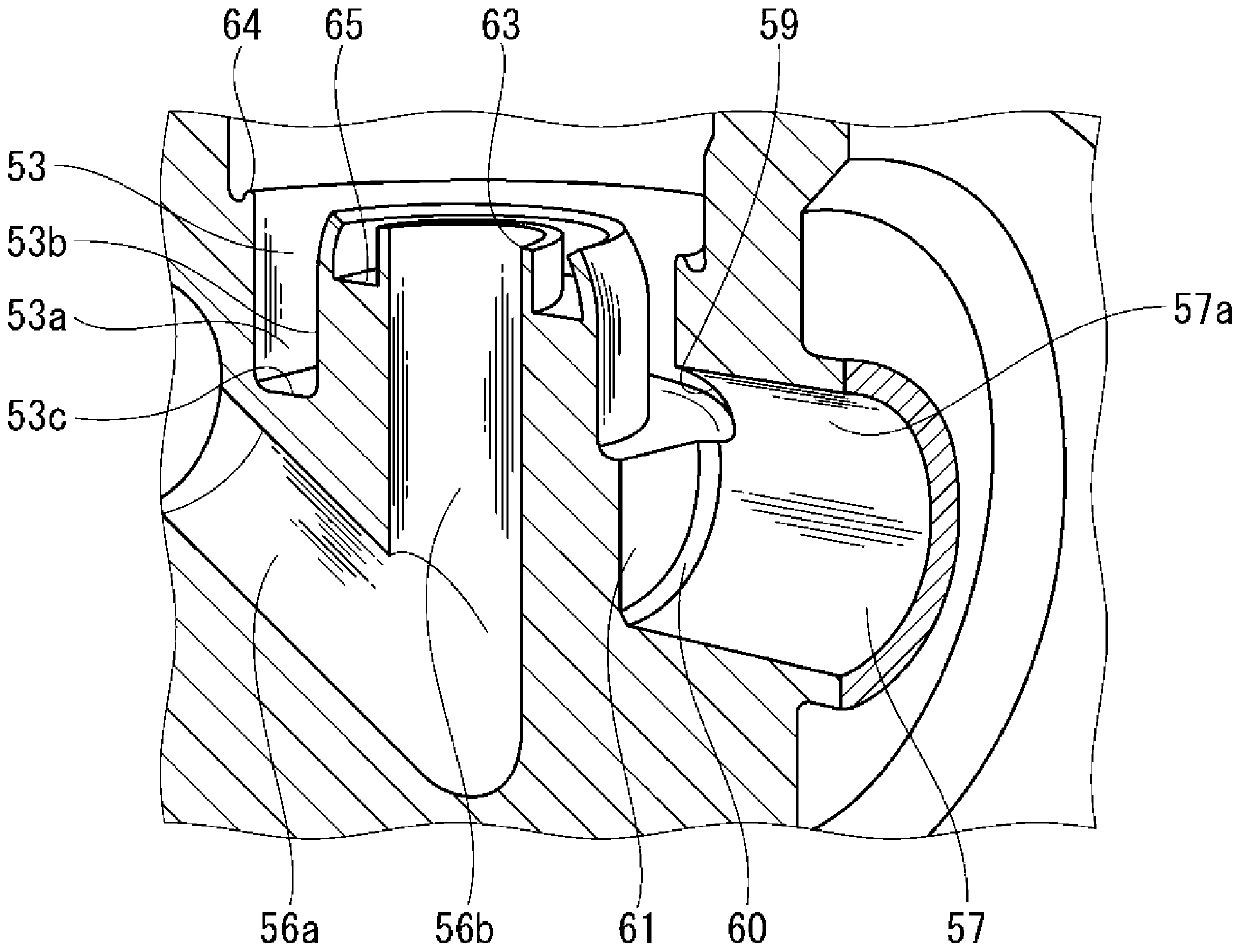

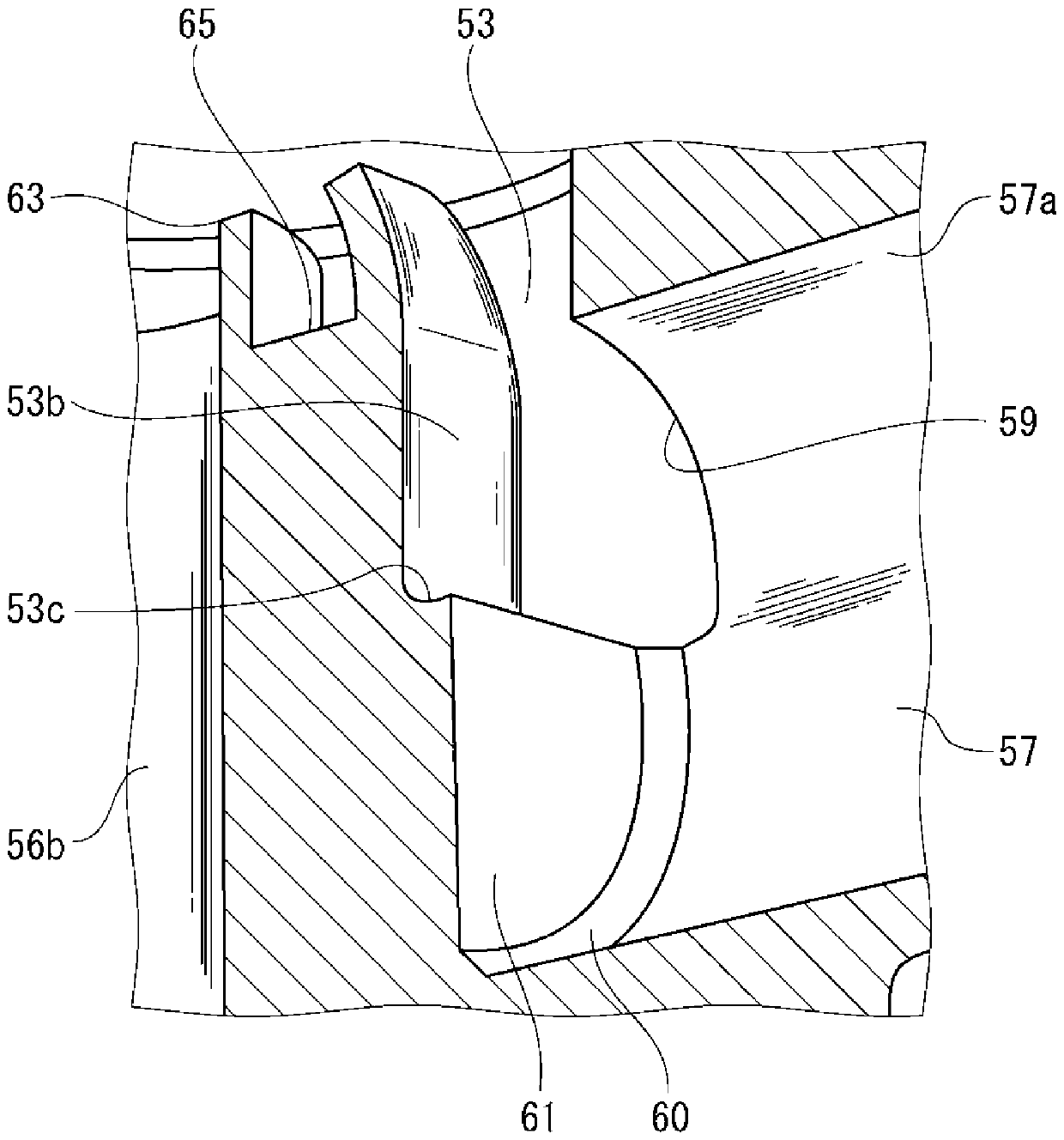

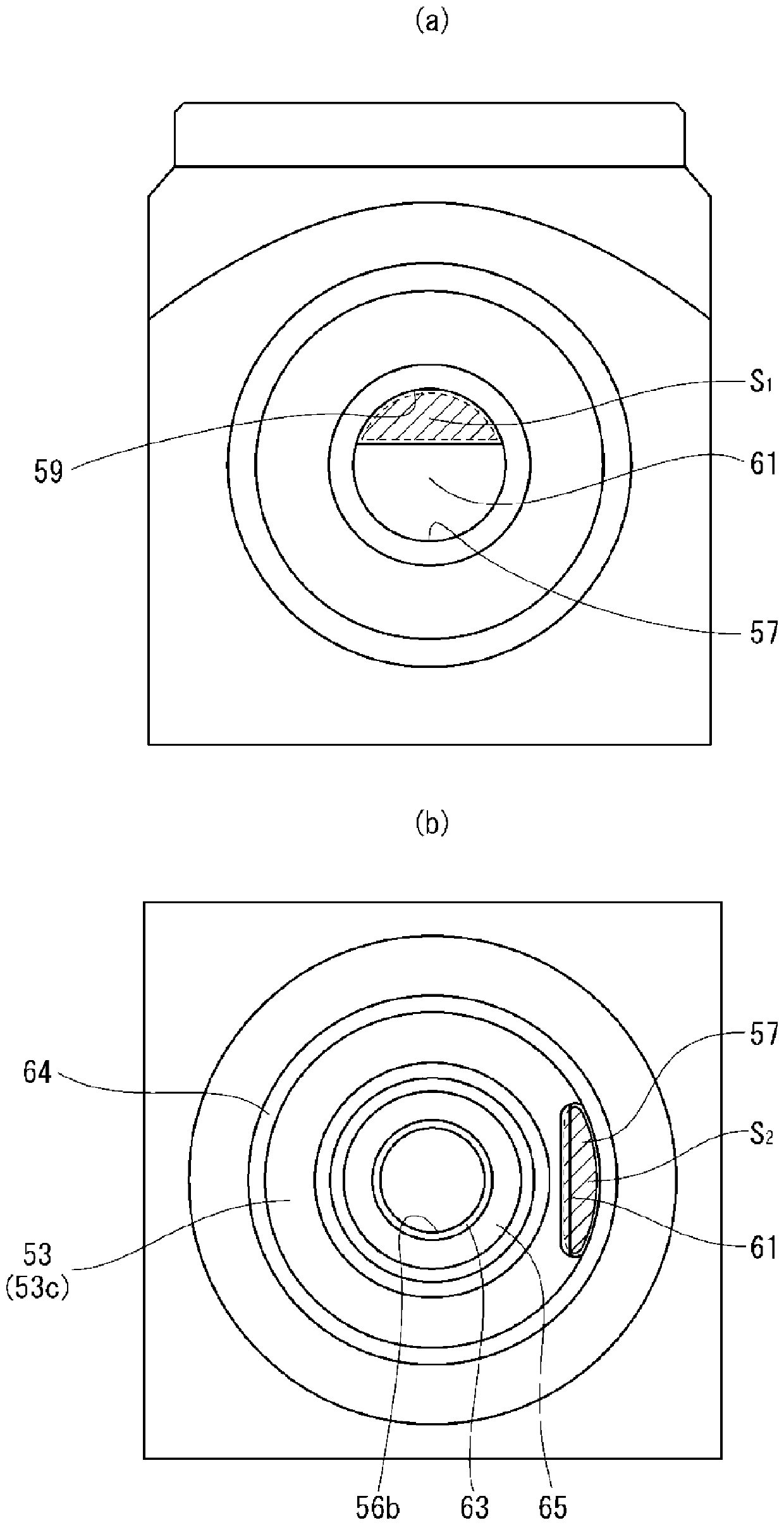

[0062] Next, fluid analysis of the diaphragm valve of this example will be described. In this fluid analysis, 0.75 was set as the target Cv value, and based on the analysis using a predetermined 3D-CAD fluid analysis software, the dimensions of each component of the flow path structure formed in the valve body 50 were found to satisfy this condition. the preferred range of values.

[0063] First of all, when discussing the size of the annular groove 53, it is obvious that a larger cross-sectional area can increase the Cv value of the valve. Therefore, if it is desired to increase the flow rate while avoiding an increase in the size of the valve, it is only necessary to make the annular groove 53 larger. It is sufficient to increase the cross-sectional area of the shaped groove 53, but there are restrictions on the structure of the valve body 50. For example, it is not impossible to make the diameter of the outer surface 53a larger than the diameter of the convex portion 64 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com