Fiber cement ridge tile flat plate automatic cutting machine

A technology of fiber cement and cutting machine, which is applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of workers' randomness, high labor intensity, high labor wages, etc., achieve high cutting efficiency, solve automatic lifting, avoid Effect of slab displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

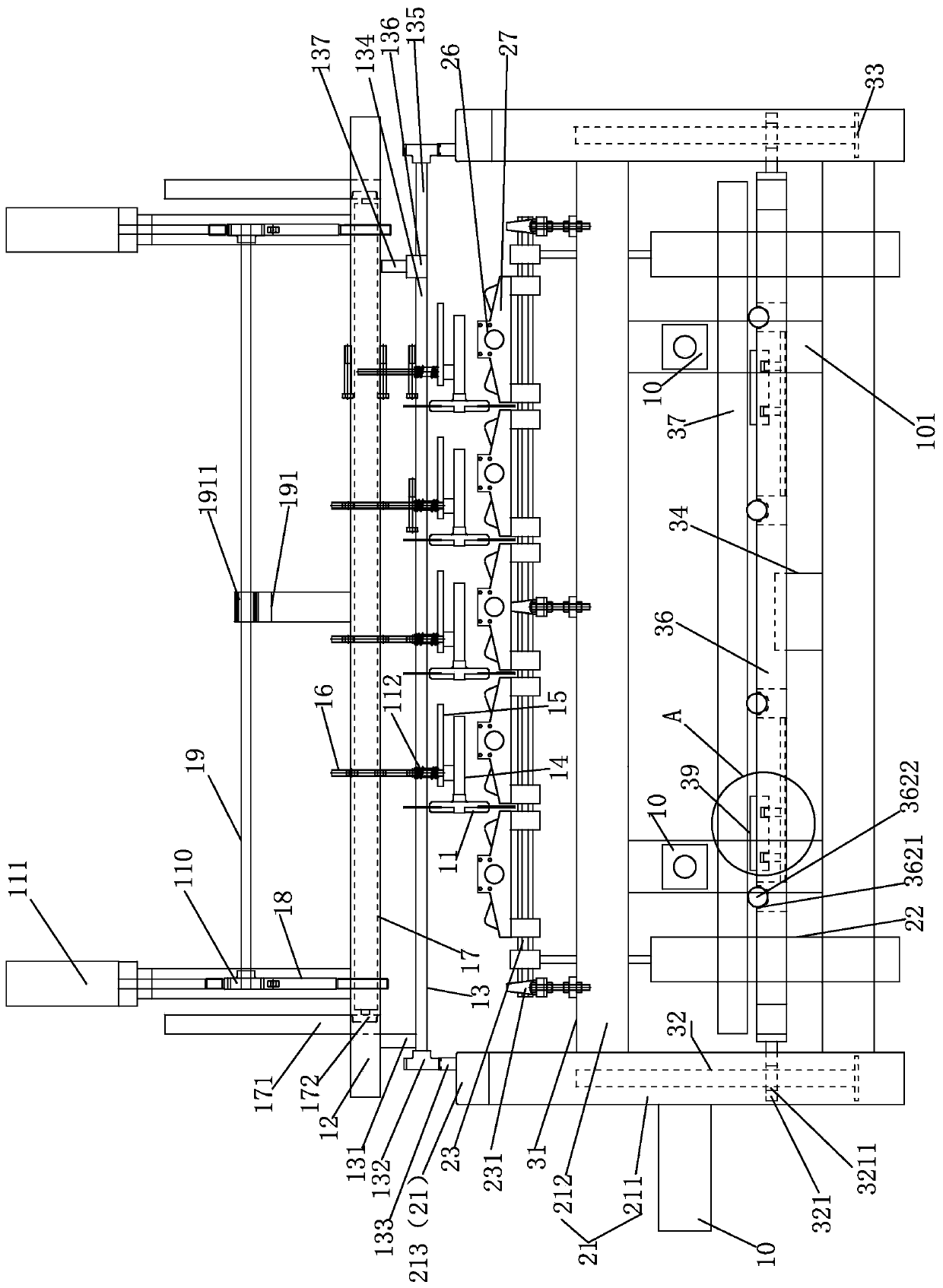

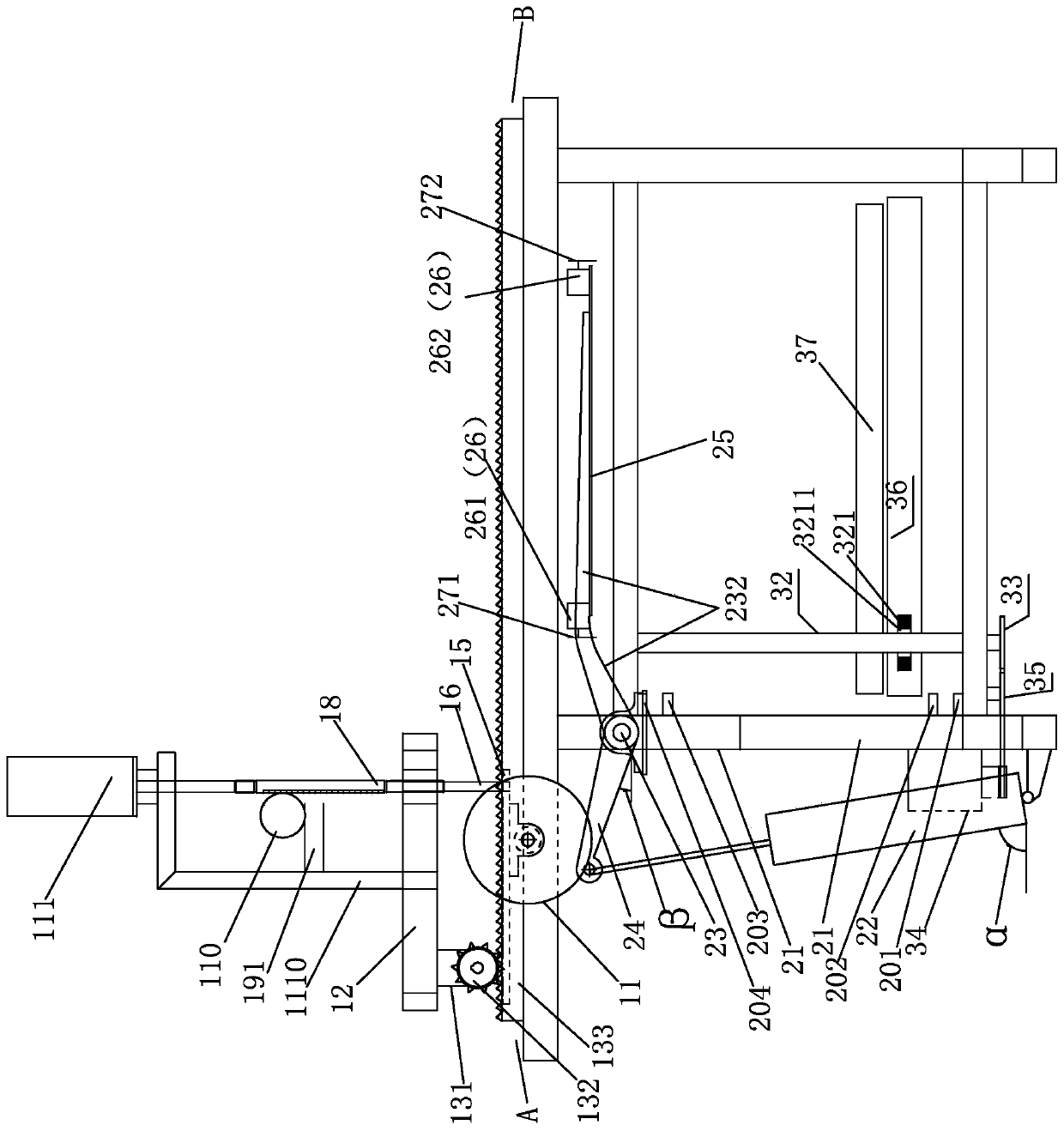

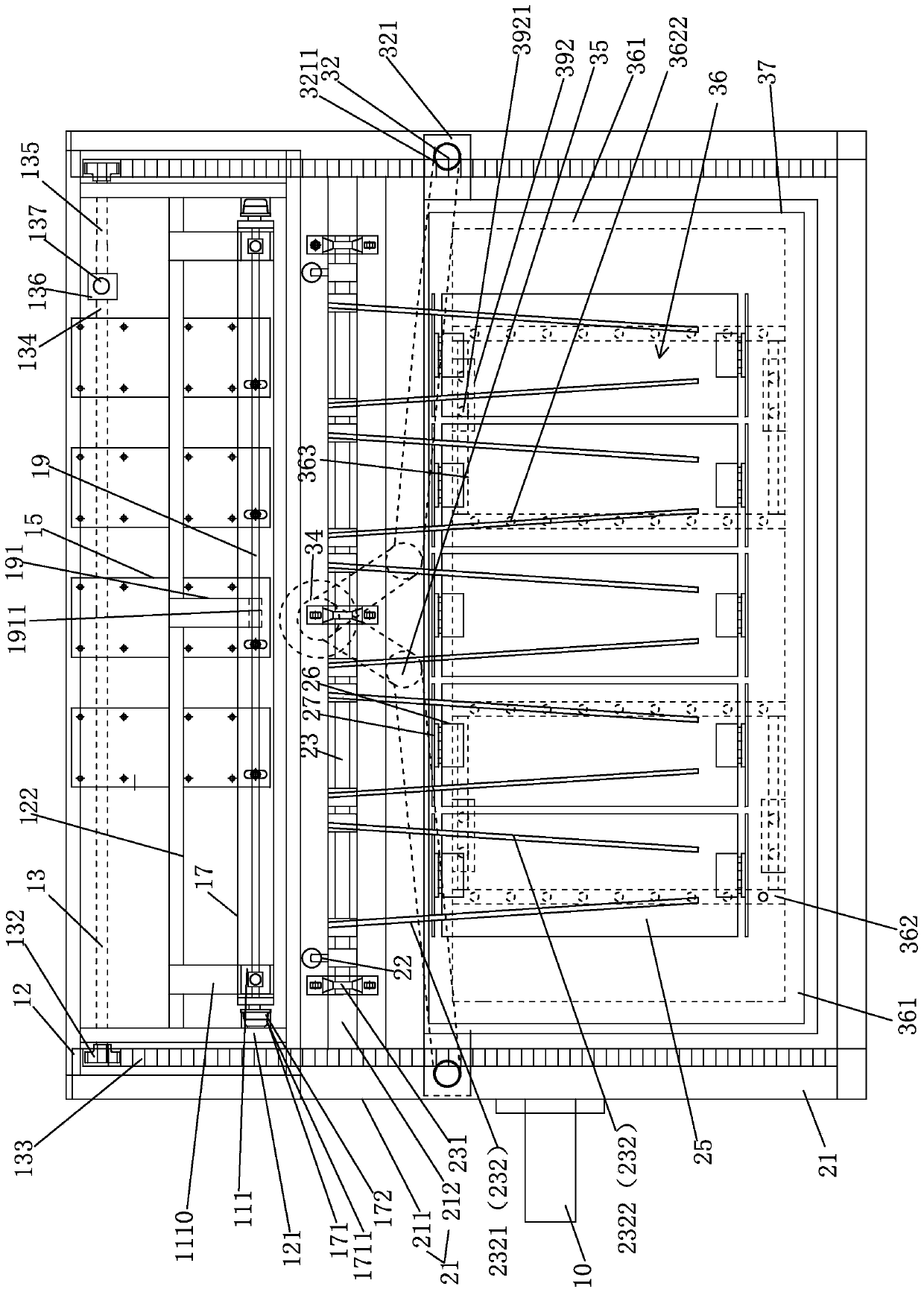

[0026] Such as Figure 1-5 A fiber cement ridge tile flat plate automatic cutting machine shown includes a knife lifting device 1, a pressing plate clamping device 2, and a lifting device 3, and is characterized in that: the upper part of the lifting device 3 is provided with a pressing plate clamping device 2, and the lifting device 3 Matching with the platen clamping device 2, the upper side of the platen clamping device 2 is provided with a knife lifting device 1, and the knife lifting device 1 moves relative to the platen clamping device 2;

[0027] Knife lifting device 1 comprises knife lifting frame 12, drive shaft 13, blade movable plate adjustment screw 16, knife lifting knife rest 17, positioning guide frame 171, cutting knife 11, cutting blade shaft 14, blade movable p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com