A heat-insulating, non-slip and high-barrier composite packaging material with a smooth and continuous printing surface

A technology of composite packaging materials and pigments and fillers, which is applied in packaging, wrapping paper, wrapping paper, etc., can solve the problems of insufficient adhesion of thermoplastic resin layers, and achieve the effects of improving adhesion, increasing loss, and reducing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

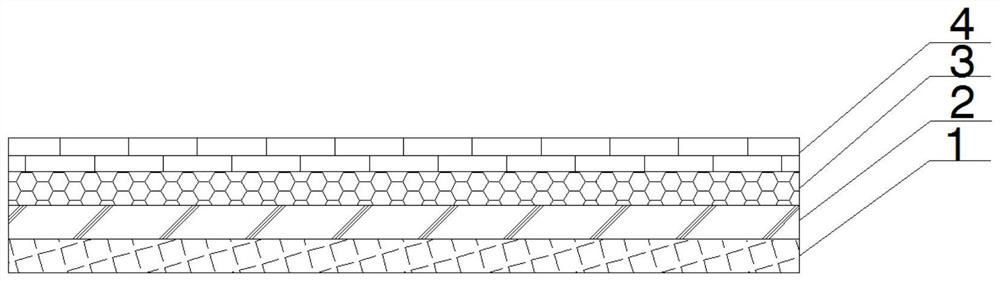

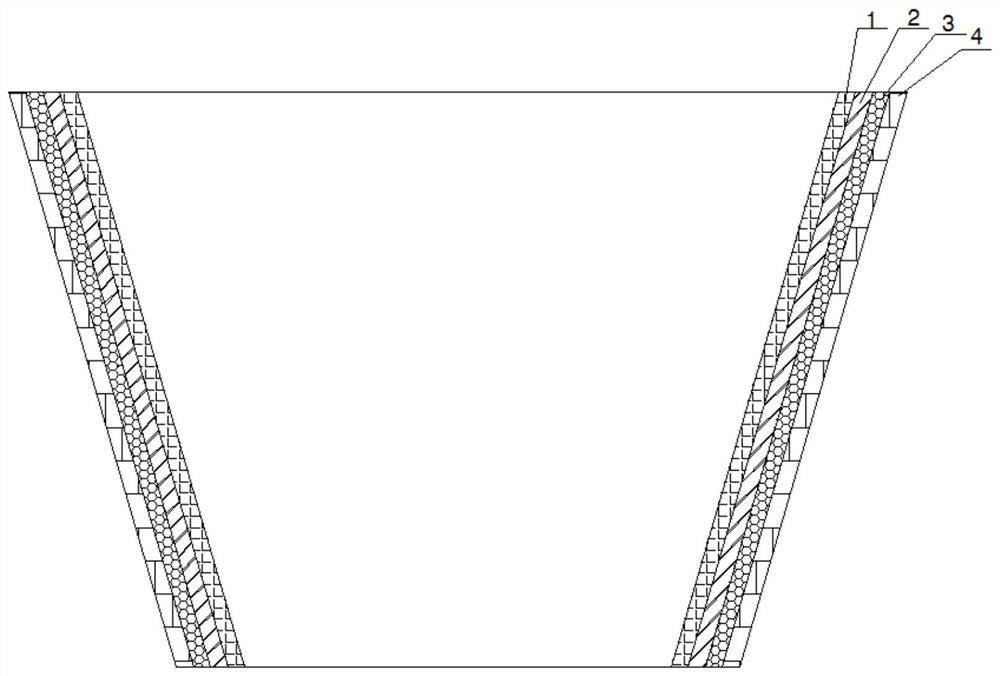

[0030] like figure 1 and figure 2 As shown, the foamed composite paper prepared in this example includes a first layer of barrier layer 1 composed of medium density polyethylene MDPE, a second layer of food-grade packaging paper layer 2, and the third layer composed of low density polyethylene LDPE The foam layer 3, the fourth layer is a coating layer 4 composed of coating latex, and the coating latex is coated on the outside of the third layer foam layer 3 by a gravure process.

[0031] In order to overcome the problems of the previously used acrylate polymers, the applicant first selected an acrylate polymer emulsion with a lower glass transition temperature, and selected an 88% water-based acrylate emulsion with a glass transition temperature of -10°C. The coating latex used in the cloth layer also includes 1% defoamer, 8% titanium oxide (particle size 5-20μm), 2% isocyanate curing agent, 1‰ leveling agent, 2‰ wetting agent, and 7‰ dispersant. The above components are ad...

Embodiment 2

[0036] The prepared foamed composite packaging material includes the first layer of barrier layer 1 composed of medium density polyethylene MDPE, the second layer of food grade packaging paper layer 2, and the third layer of foam layer 3 composed of low density polyethylene LDPE ,

[0037] Among them, the medium density polyethylene MDPE is 12-28 g / m 2 , food-grade packaging paper selection 160-350 g / m 2 Paper for packaging materials; low-density polyethylene LDPE layer is 15-45 g / m 2 ;

[0038] The fourth layer is a coating layer 4 made of coated latex, and the coating layer 4 is coated on the outside of the third foaming layer 3 by using a gravure printing process. The coating layer used in the present embodiment selects water-based polyurethane emulsion with a lower glass transition temperature, wherein coating layer 4 comprises 88% of aqueous polyurethane emulsion, defoamer 8‰, titanium oxide (5-20 μm in particle size) 9%, Isocyanate curing agent 1%, leveling agent 1...

Embodiment 3

[0052] The barrier layer 1 composed of the first layer of medium density polyethylene MDPE, the second layer of food grade packaging paper layer 2, and the third layer of foam layer 3 composed of low density polyethylene LDPE are consistent with embodiment 2, and the present embodiment uses The composition of the coating latex is as follows: water-based polyurethane emulsion 88%, defoamer 8‰, titanium oxide (particle size 5-20 μm) 9%, leveling agent 2‰, wetting agent 5‰, dispersant 1.5%; Add it to the dispersion stirring tank, stir and disperse evenly at 25-35°C, with a rotation speed of 1000r / min to form a coated latex. The coated latex is used to prepare a heat-insulating, non-slip and high-barrier compound with a smooth and continuous printing surface. Packaging Materials;

[0053] Its specific preparation method is: use the food-grade packaging laminating paper of 19.5+250+39 g / m2 composed of foam layer 3, food-grade packaging paper layer 2 and barrier layer 1 as the base ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com