Feeding device for calcium-zinc stabilizer

The technology of calcium-zinc stabilizer and feeding device is applied in the field of feeding device for calcium-zinc stabilizer and calcium-zinc stabilizer, which can solve the problems of blocked flow, arching and clogging of calcium-zinc stabilizer raw materials, and difficulty in feeding. To achieve the effect of avoiding the central flow pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

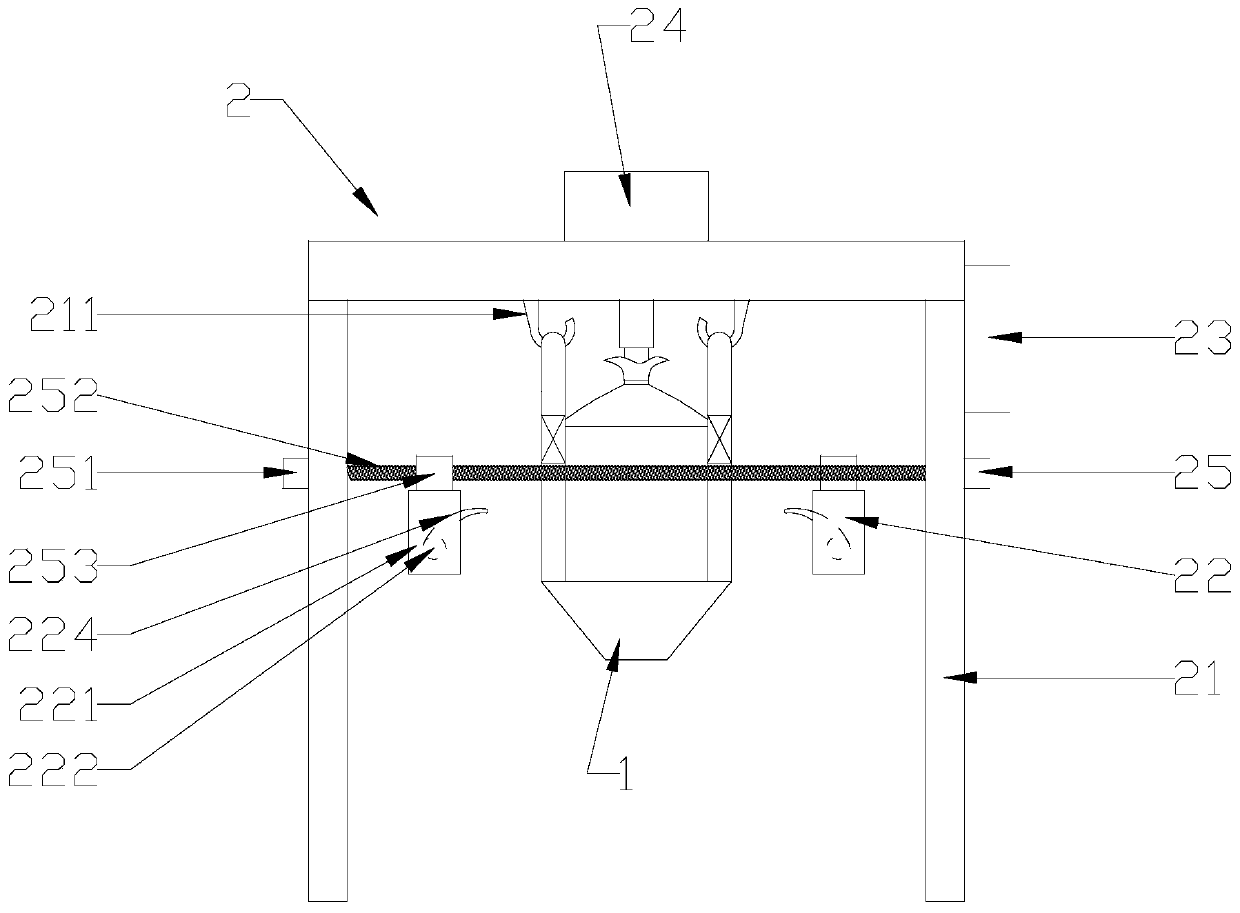

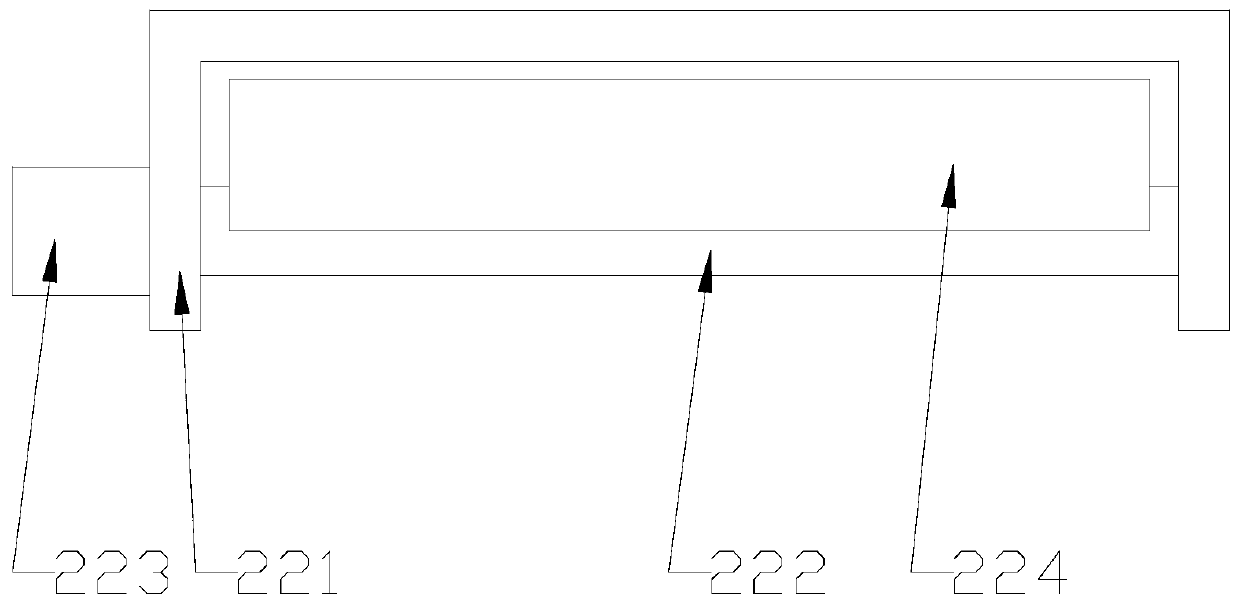

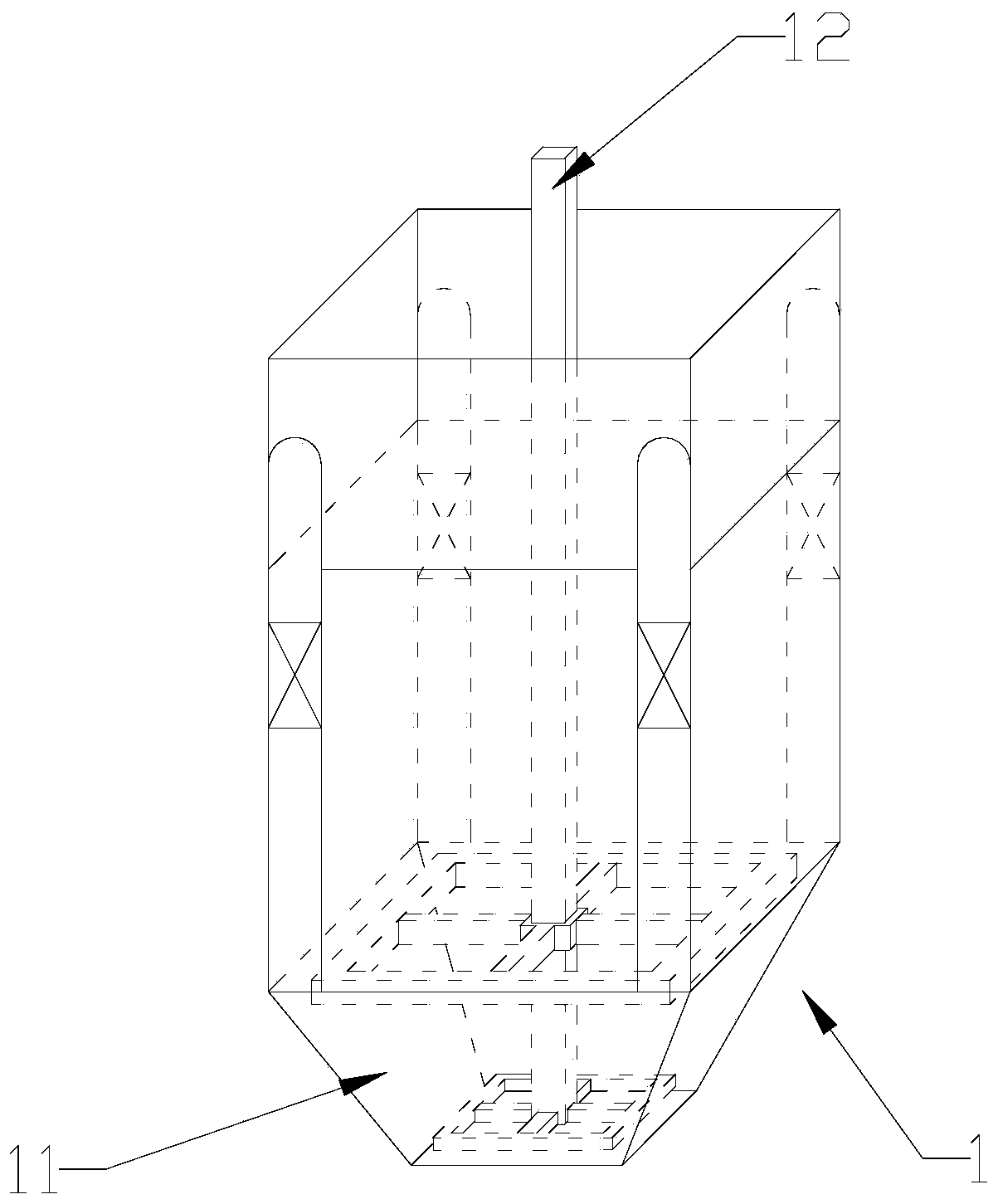

[0027] refer to Figure 1 to Figure 5 , a feeding device for a calcium-zinc stabilizer of the present invention, comprising a large bag 1 and an arch breaking device 2, the large bag 1 includes a bag body 11 and a telescopic frame 12, and the bag body 11 includes a bag body 111 and a uniformly arranged Several slings 113 on the outside of the bag main body 111, the telescopic frame 12 includes a central rod 121, a first frame body 122 sleeved on the central rod 121 and a second frame body 123 fixed at the bottom end of the central rod 121. The first frame body 122 and the second frame body 123 are respectively fixed inside the bag body body 111 through several cable ties 112 provided inside the bag body 11. The arch breaking device 2 includes a frame 21, two The scraper mechanism 22 on the side, the cylinder 24 located in the center of the top plate of the frame 21, and the control device 23 electrically connected to the scraper mechanism 22, the scraper mechanism 22 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com