Automatically-telescoping dust removal device used by stacking machine for stacking, and operation method thereof

A technology of automatic telescopic and dust removal devices, which is applied in the direction of conveyor control devices, smoke and dust removal, cleaning methods and appliances, etc., can solve environmental pollution and other problems, achieve diffusion suppression, fast and effective operation methods, and improve work efficiency and safety efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

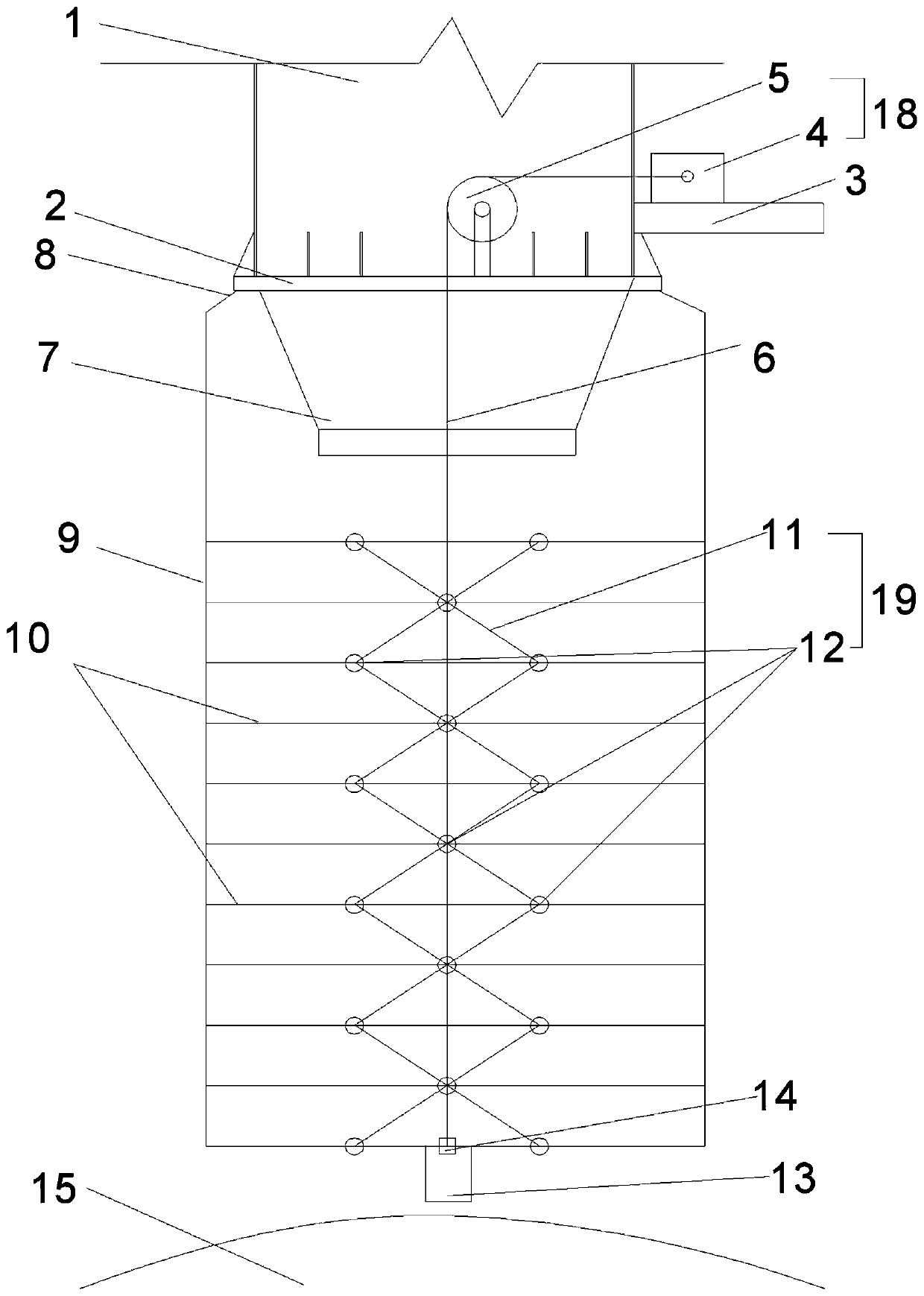

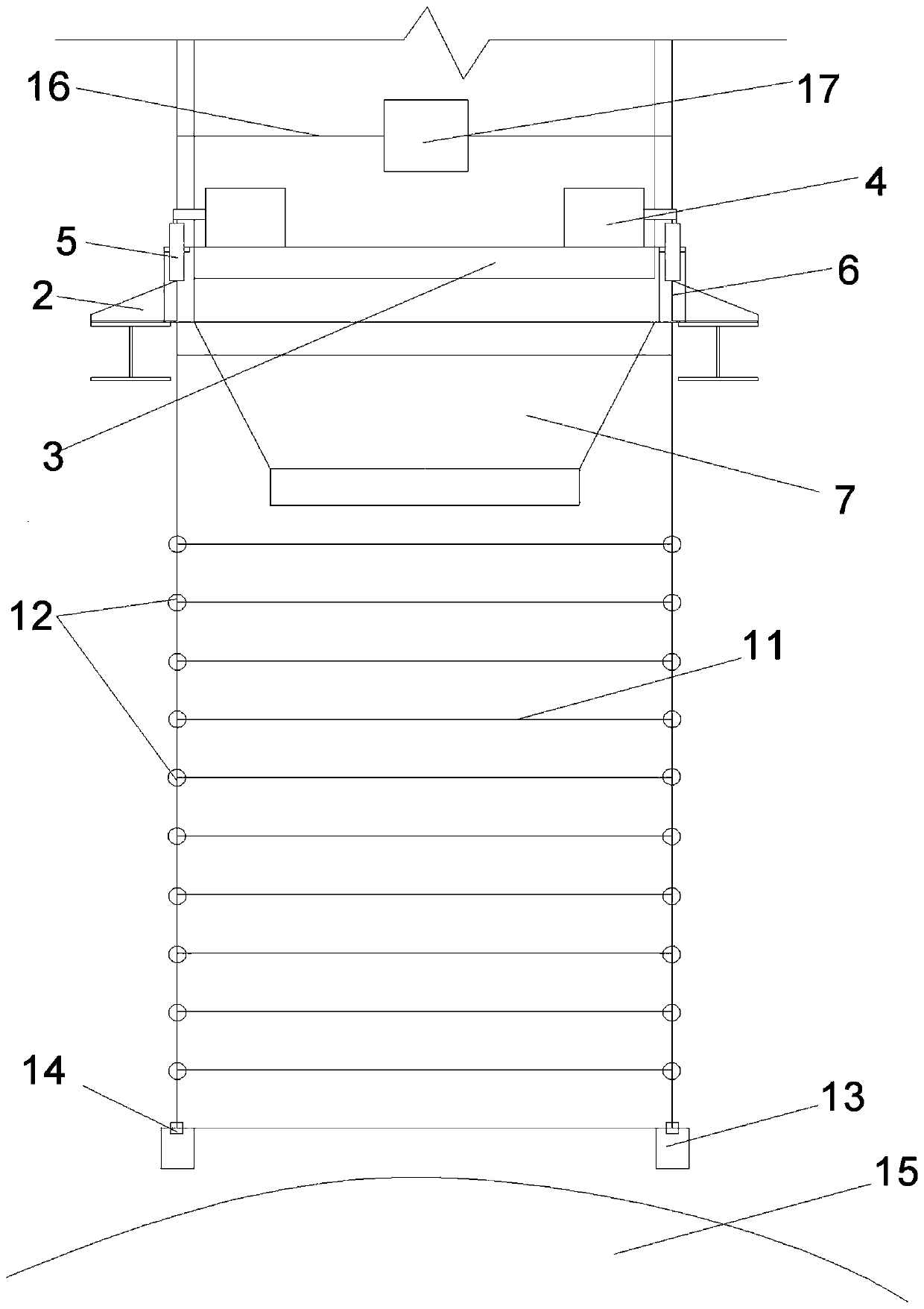

[0031] Such as Figure 1 to Figure 2 As shown, an automatic telescopic dust-proof device for stacking materials of a stacker includes an upper hopper 1 and an upper platform 3 and a lower platform 2 which are fixedly welded on the cantilever frame of the stacker, and the lower platform 2 is provided with and The upper hopper 1 has a through hole matching the lower port, the upper hopper 1 penetrates the through hole and is fixedly connected to the lower platform 2, and further includes an electrical control device 17, a dust removal device body, a steel wire rope 6 and a steel wire rope hoist Device 18, the electrical control device 17 is connected to the wire rope hoisting device 18 through a signal line 16; the dust removal device body includes a fixed frame 8, a skeleton unit 10, a telescopic part 19 and a dust removal cover 9, and the fixed frame 8 is connected Fixed to the lower surface of the lower platform 2, the skeleton unit 10 is fixedly arranged at the lower end of t...

Embodiment 2

[0038] Such as Figure 1 to Figure 2 As shown, an operation method of an automatic telescopic dust removal device for stacking materials of a stacker includes the following specific steps:

[0039] Step 1: Determine the pitch height of the stacker boom and position it;

[0040] Step 2: Install the retractable dust removal device body;

[0041] Step 3: Install the steel wire rope 6 and the steel wire rope hoisting device 18, and use the signal wire 16 to connect the reel driving device 4 in the steel wire rope hoisting device 18 to the electric control device 17;

[0042] Step 4: Install the position detector 13 and connect the position detector 13 with the electrical control device 17 with the signal line 16;

[0043] Step 5: Turn on the electrical control device 17, and set the fully extended length value of the dust removal device body, the height value of the pile 15 and the minimum distance between the height of the pile 15 and the lowest end of the dust removal device body on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com