A kind of preparation method and application of aminated graphene oxide modified solvent-free polyurethane resin

A polyurethane resin, amination technology, used in textiles and papermaking, etc., can solve the problems of application limitation and insufficient thermal conductivity, and achieve the effects of long pot life, high production efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

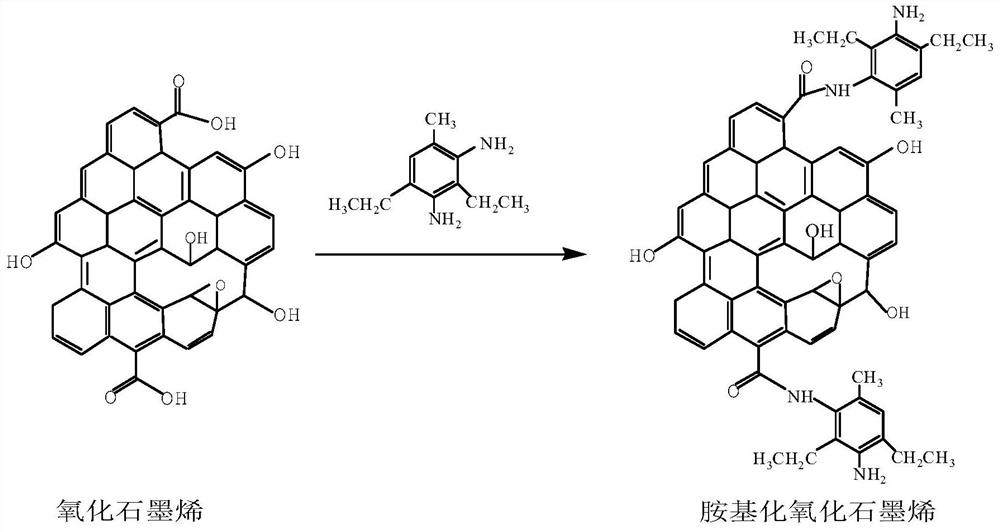

[0035] A preparation method for aminated graphene oxide modified solvent-free polyurethane resin, comprising the following steps:

[0036] (1), preparation of aminated graphene oxide:

[0037] Take 1-5 parts by weight of graphene oxide, 800-1000 parts by weight of N,N-dimethylformyl, and 1-8 parts by weight of 3,5-diethyl-2, 4-toluenediamine, after mixing the three, carry out stirring reaction for a period of time to obtain aminated graphene oxide;

[0038] (2), utilize the aminated graphene oxide that step (1) obtains to prepare curing agent:

[0039] Disperse the aminated graphene oxide prepared in step (1) in the diamine, and then stir evenly to obtain the curing agent, wherein the weight parts of the aminated graphene oxide and the diamine are as follows:

[0040] 2-5 parts of aminated graphene oxide,

[0041] 10-20 parts of diamine;

[0042] (3), prepare polyurethane prepolymer:

[0043] Take 20-30 parts by weight of diisocyanate, 0.05-0.5 parts by weight of antioxid...

Embodiment 1

[0057] A preparation method for aminated graphene oxide modified solvent-free polyurethane resin, comprising the following steps:

[0058] (1), preparation of aminated graphene oxide:

[0059] Take 1g of graphene oxide and 800g of N,N-dimethylformyl, first mix and ultrasonicate for 1.6h, then add 1g of 3,5-diethyl- 2,4-toluenediamine, the three were mixed and stirred at 22°C for 23 hours to obtain the reactant. The reactant was washed 5 times, and then vacuum-dried at 33°C for 70 hours to obtain aminated graphene oxide ;

[0060] (2), utilize the aminated graphene oxide that step (1) obtains to prepare curing agent:

[0061] Take step (1) to prepare 2g of aminated graphene oxide and 10g of 2,4-diamino-3,5-dimethylthiochlorobenzene and mix and stir evenly at room temperature.

[0062] (3), prepare polyurethane prepolymer:

[0063] Add 20g of 4,4'-diphenylmethane diisocyanate, 0.05g of antioxidant 1010, and 85g of polytetrahydrofuran diol (PTMG-2000) into a three-necked flas...

Embodiment 2

[0068] A preparation method for aminated graphene oxide modified solvent-free polyurethane resin, comprising the following steps:

[0069] (1), preparation of aminated graphene oxide:

[0070] Take 2 g of graphene oxide and 900 g of N,N-dimethylformyl, first mix and ultrasonicate for 2 hours, then add 4 g of 3,5-diethyl-2 , 4-toluenediamine, mixing the three, stirring and reacting at 25°C for 24 hours to obtain a reactant, washing the reactant 7 times, and then vacuum-drying at 35°C for 73h to obtain aminated graphene oxide;

[0071] (2), utilize the aminated graphene oxide that step (1) obtains to prepare curing agent:

[0072] Take step (1) to prepare 4g of aminated graphene oxide and 15g of 3,5-dimethylthiotoluenediamine and mix and stir evenly at room temperature.

[0073] (3), prepare polyurethane prepolymer:

[0074] Add 25g of isophorone diisocyanate, 0.2g of antioxidant 245 and 80g of polycarbonate diol (PCDL-1000) into a three-necked flask in sequence, raise the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com