Optical module stress release method

A stress release, optical module technology, applied in the field of optical communication, can solve problems such as failure, optical module power and performance changes, incomplete optical module stress release, etc., to ensure stability and reliability, process simplicity, and avoid power deviation. and the effect of changes in performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

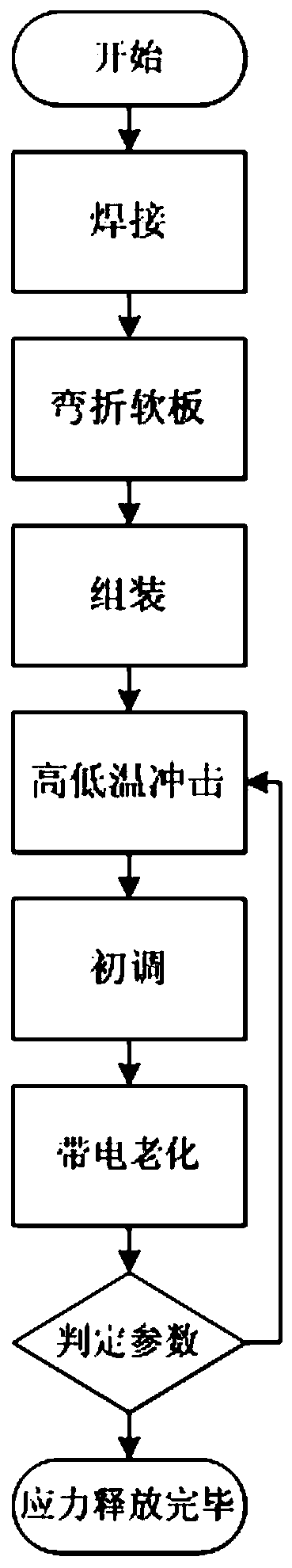

[0020] (1) Soldering: Use Weller PUD 81 welding workbench with a power of 95W, adjust the temperature of the soldering iron to 360-380°C, and use lead-free solder wire with a diameter of 0.5mm to solder the optical device to the PCBA board of the optical module through the soft board. Welding time for each solder spot shall not exceed 3 seconds;

[0021] (2) Bending the flexible board: the size of the flexible board is greater than 12mm, and the distance between the bottom of the device and the PCBA board is less than 2mm. The flexible board is bent into an S shape. Where the flexible board bends, the arc radius must be ≥ 1mm.

[0022] (3) Assembly: Place the optical device, bent soft board and PCBA board into the optical module casing, put the snap ring of the optical device pin into the corresponding position of the optical module casing, and adjust the optical device and PCBA board Arrive at the proper position, and visually observe whether the PCBA board is parallel to the...

specific Embodiment approach 2

[0028] This embodiment adopts basically the same processing method as in Example 1, the difference is (2) bending the soft board: the size of the soft board is less than 10mm, and the distance from the bottom of the device to the PCBA is greater than 3mm, and the soft board is bent into a U shape. Where the corner is turned, it is necessary to satisfy the arc radius ≥ 1mm.

specific Embodiment approach 3

[0030] This embodiment uses basically the same processing method as in Embodiment 1, the difference is (2) Bending the flexible board: use a simple and intuitive judgment method to bend the flexible board, first bend the flexible board into a U shape, and then place it in the optical module In the casing, observe the soft board when installing the top cover. If the U-shaped bend is flattened, the soft board needs to be bent into an S-shape; otherwise, the U-shape meets the requirements.

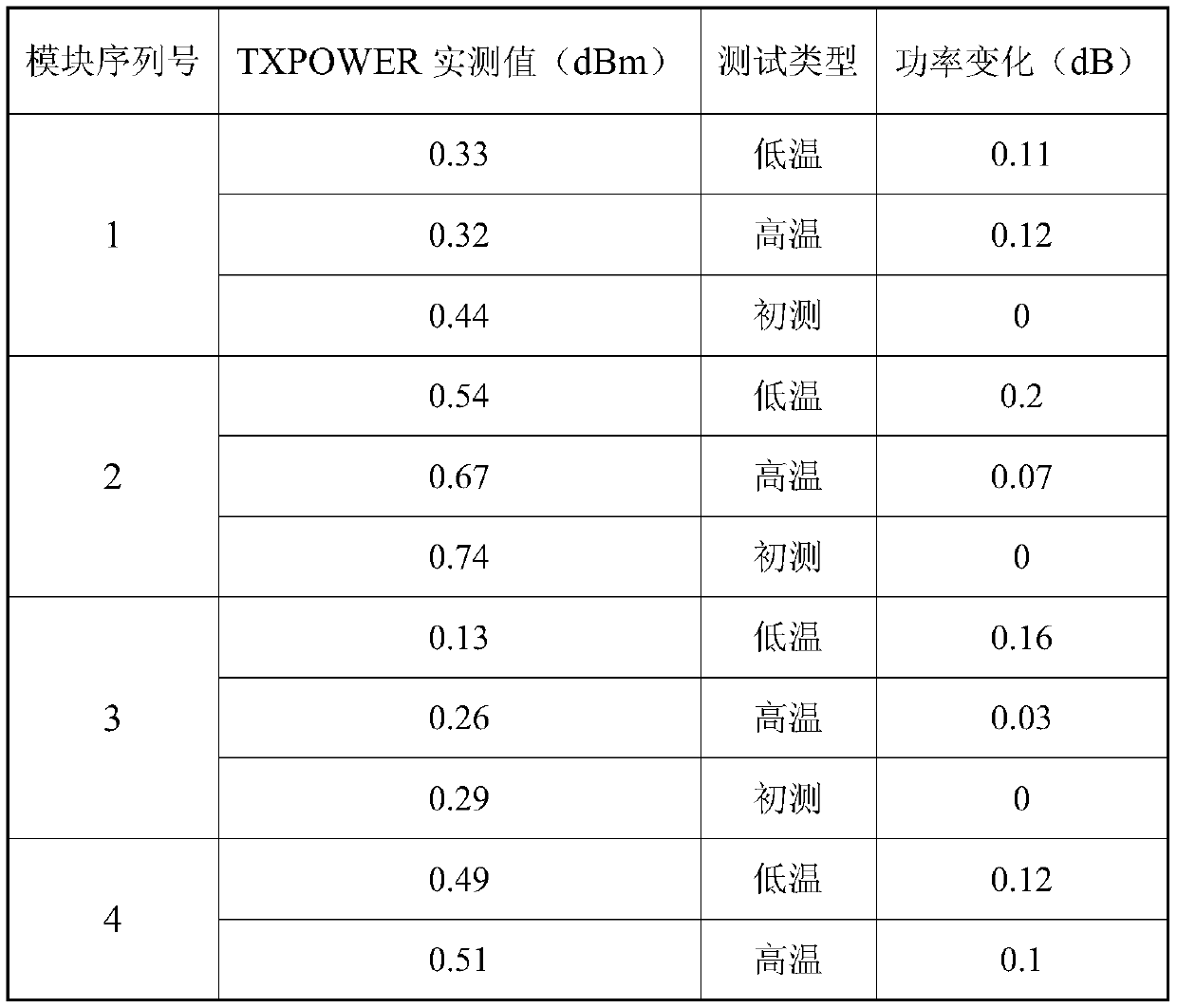

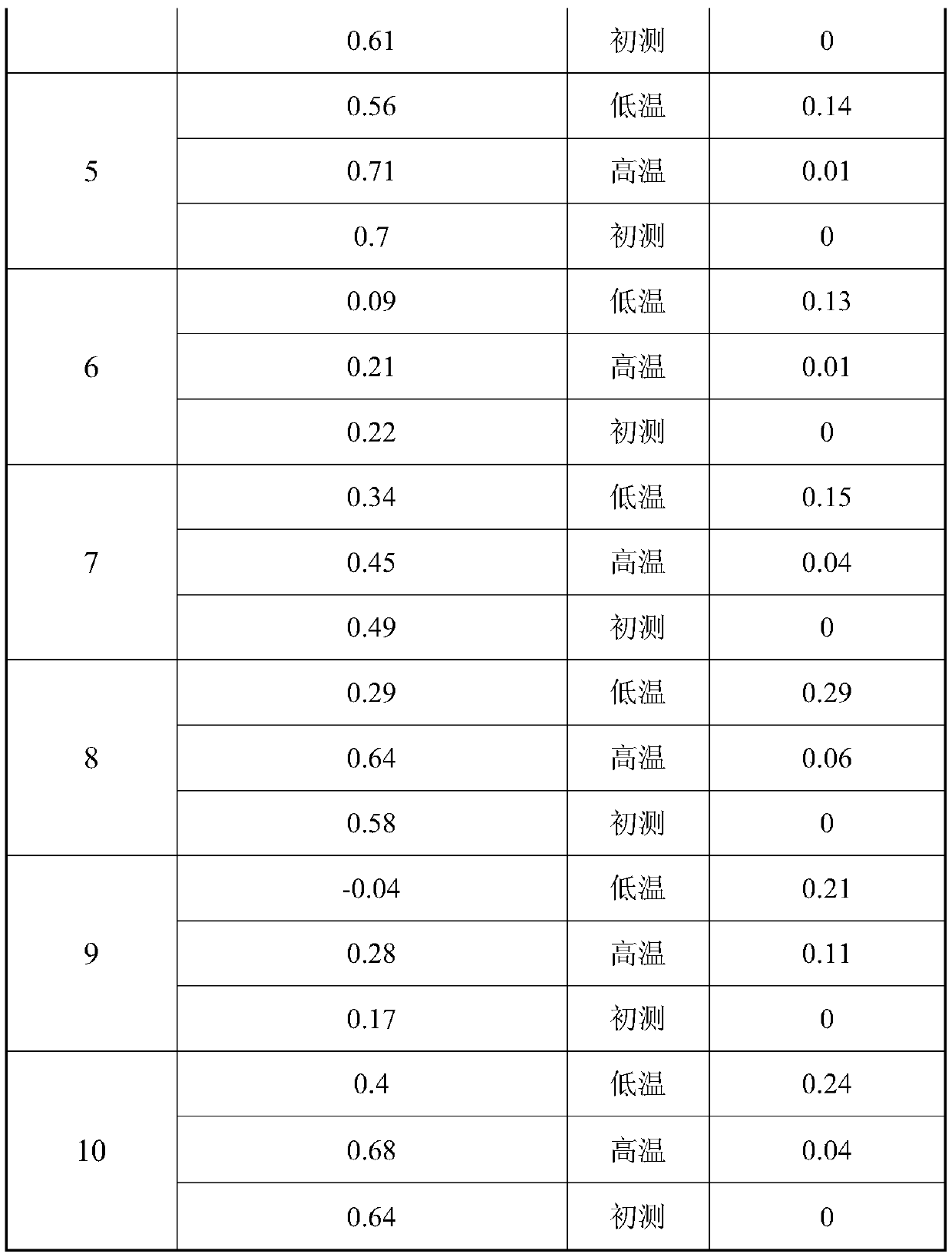

[0031] Table 1 Comparison of test results before and after stress release of optical modules

[0032]

[0033]

[0034] Using the stress release method of the optical module described in the above embodiment, the test results in Table 1 can be achieved by bending the flexible board into an S-shape or a U-shape. The data in the table are the initial adjustment and final inspection test data at room temperature 25°C It can be seen from the power changes in the table that the power changes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com