High-temperature-resistant anti-ultraviolet sunhat material and manufacturing method thereof

A technology of anti-ultraviolet and production methods, applied in the fields of rayon manufacturing, textile, fiber chemical characteristics, etc., can solve the problem of easy penetration of fabrics and irradiate the head, and achieve the effect of excellent anti-ultraviolet performance and excellent high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

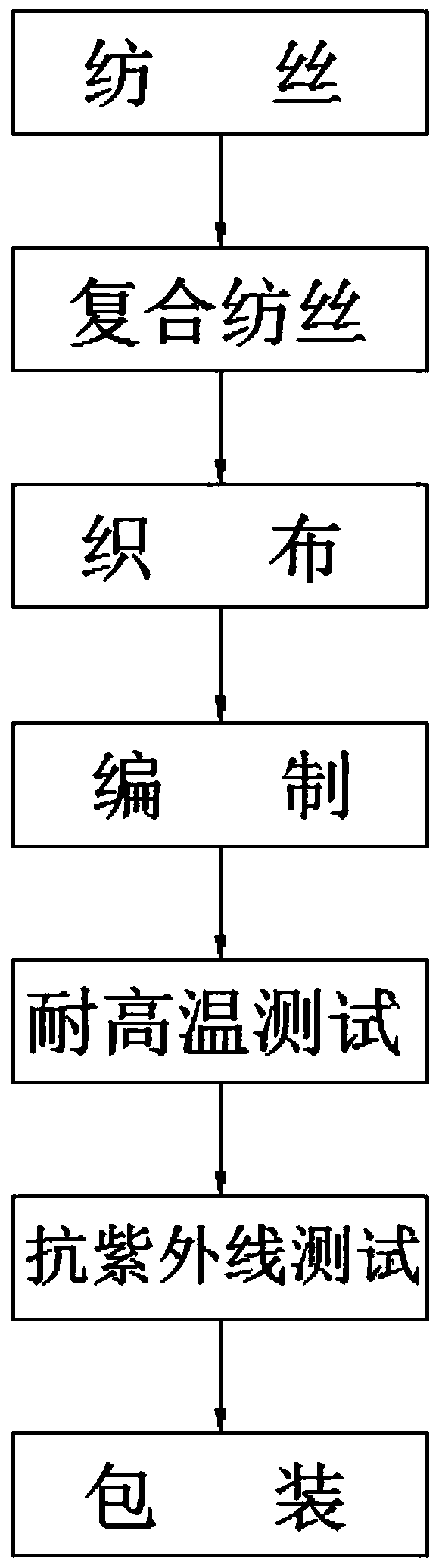

Image

Examples

Embodiment

[0020] The heat-resistant and UV-resistant sun hat material and its manufacturing method listed in this embodiment are made according to the following method. The three raw materials of glass fiber, carbon fiber and fine denier acrylic fiber are spun on a spinning machine to spin The glass fiber, carbon fiber and fine-denier acrylic fiber after the silk form the high temperature resistant and UV resistant spinning material, and the spinning machine is used again to add the wrinkle-removing agent and the UV protection agent to the high temperature resistant and UV resistant spinning material. Composite spinning treatment, that is, to improve the anti-wrinkle and anti-ultraviolet effects of high-temperature and UV-resistant spinning materials. Use a loom to make polyamide fibers into nylon fabrics. The woven nylon fabrics are spun with high-temperature and UV-resistant spinning materials. The silk material is woven into the fabric material of the sun visor, and the woven material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com