Construction method of building pile foundation

A construction method and technology of construction piles, which are applied in construction, foundation structure engineering, sheet pile walls, etc., can solve the problems of high construction difficulty, low construction difficulty, and long construction time, so as to reduce movable space and increase connection stability Sexuality and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

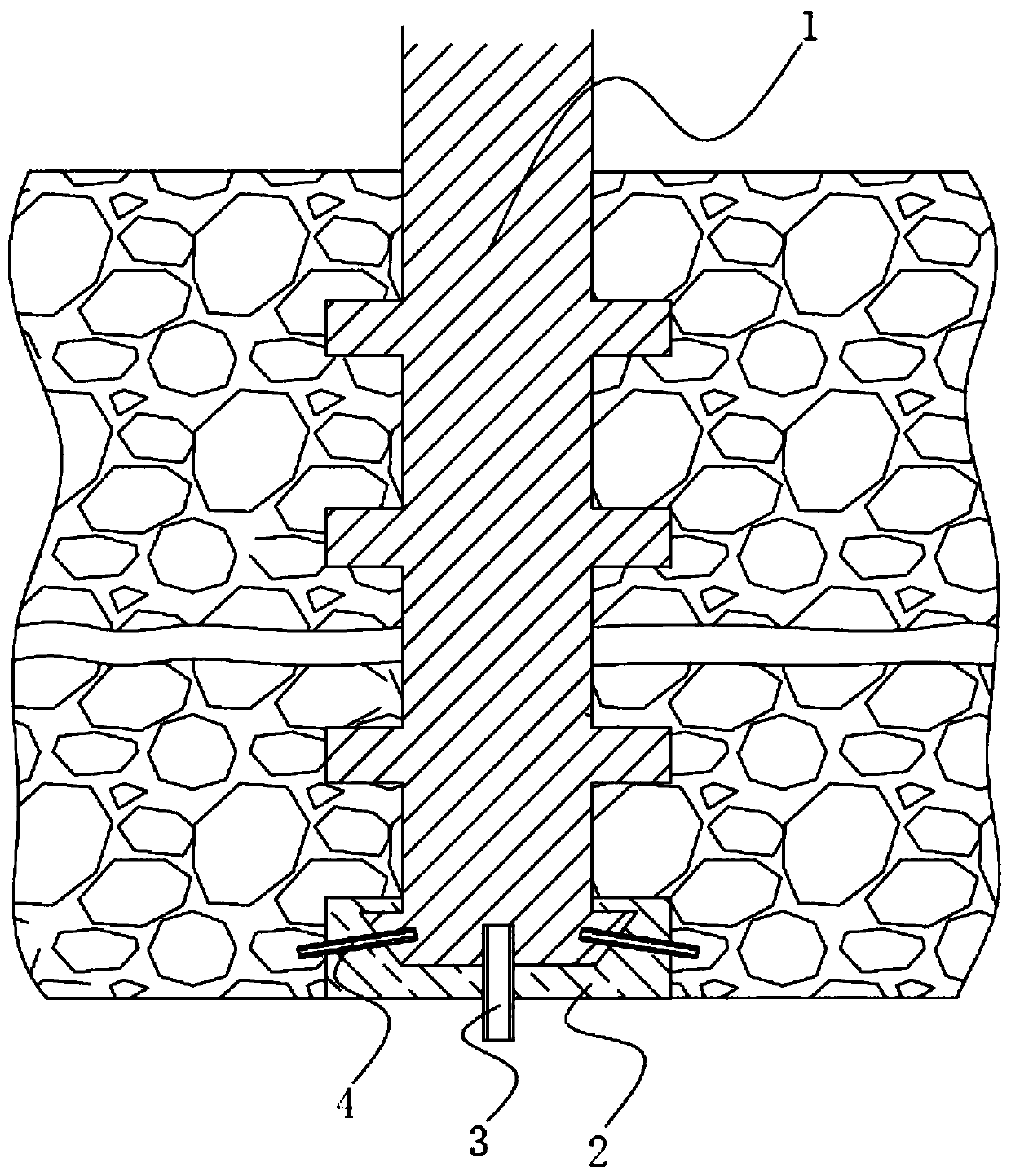

[0038] Embodiment one: a kind of building pile foundation construction method, such as figure 1 shown, including the following steps:

[0039] Prefabricated foundation hole support platform: design the foundation hole support platform 2 forming mold according to the shape and scale of the foundation hole, and then pour concrete into the mold to form the support platform 2. The support platform 2 has a circular platform-shaped opening and is dried and formed; it can be used The support platform 2 is designed into three equal parts and manufactured separately, and the three support platforms can be combined into a complete support platform 2, and a fixing hole can be reserved on each support platform, and the fixing holes are set at an inclined angle Towards the center line of the foundation hole upwards, the inclination angle is 5-10°, which is convenient for inserting the steel pipe 4 for fixing in the later stage. At the same time, there are one-third cylindrical gaps in the ...

Embodiment 2

[0047] Embodiment 2: A construction method for building pile foundations. The difference from Embodiment 1 is that steel pipes or steel bars are directly prefabricated in the support platform when making the support platform. Or the steel bar can be combined more firmly with the support platform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com