FFU four-air-duct box structure

A technology with box structure and four air ducts is used in liquid fuel engines, components of pumping devices for elastic fluids, pump control, etc., which can solve the problem of insufficient FFU box structure and support strength, and low overall FFU efficiency. , difficult to improve the space and other issues, to achieve the effect of simple structure, easy assembly, smooth airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

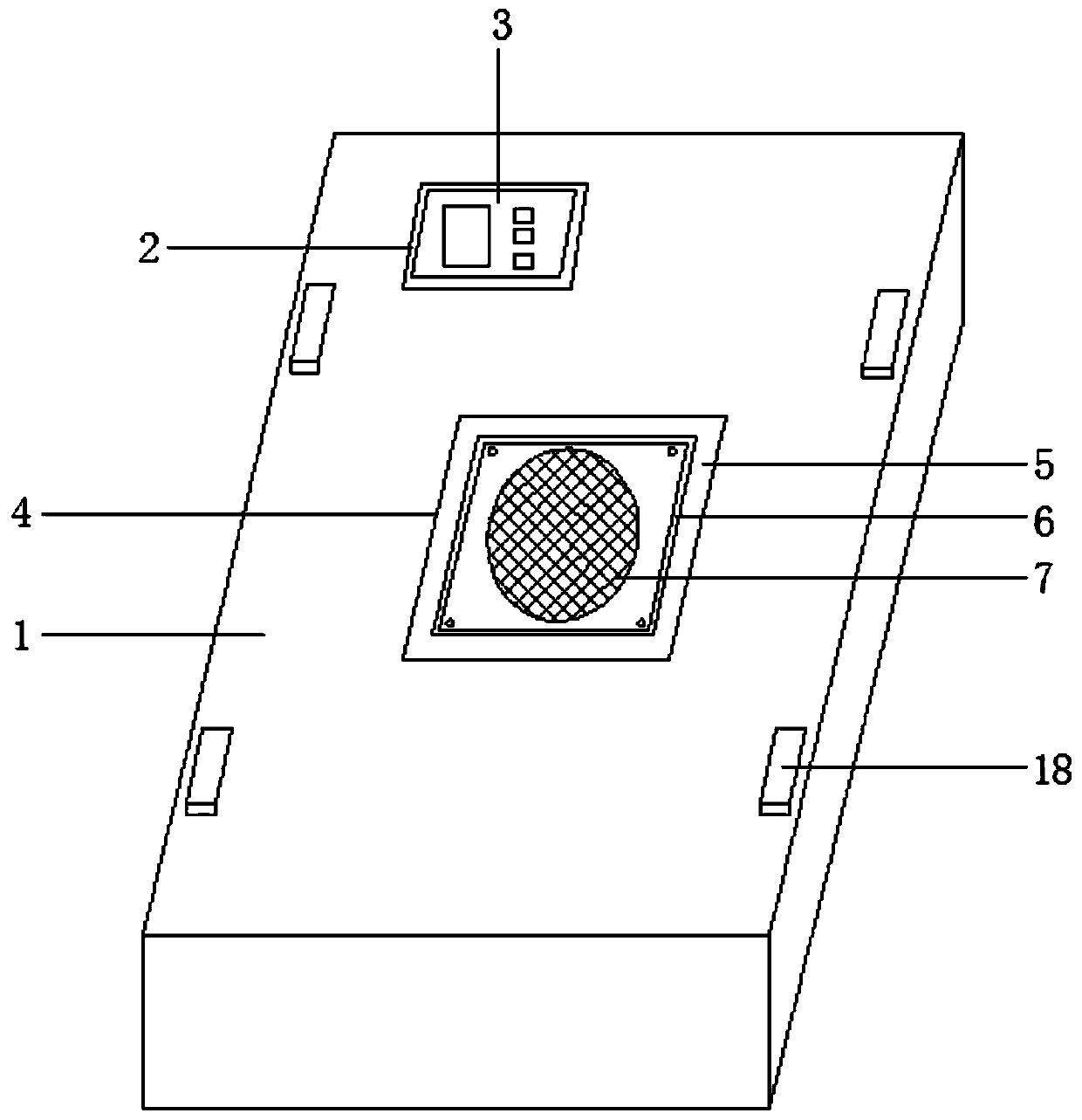

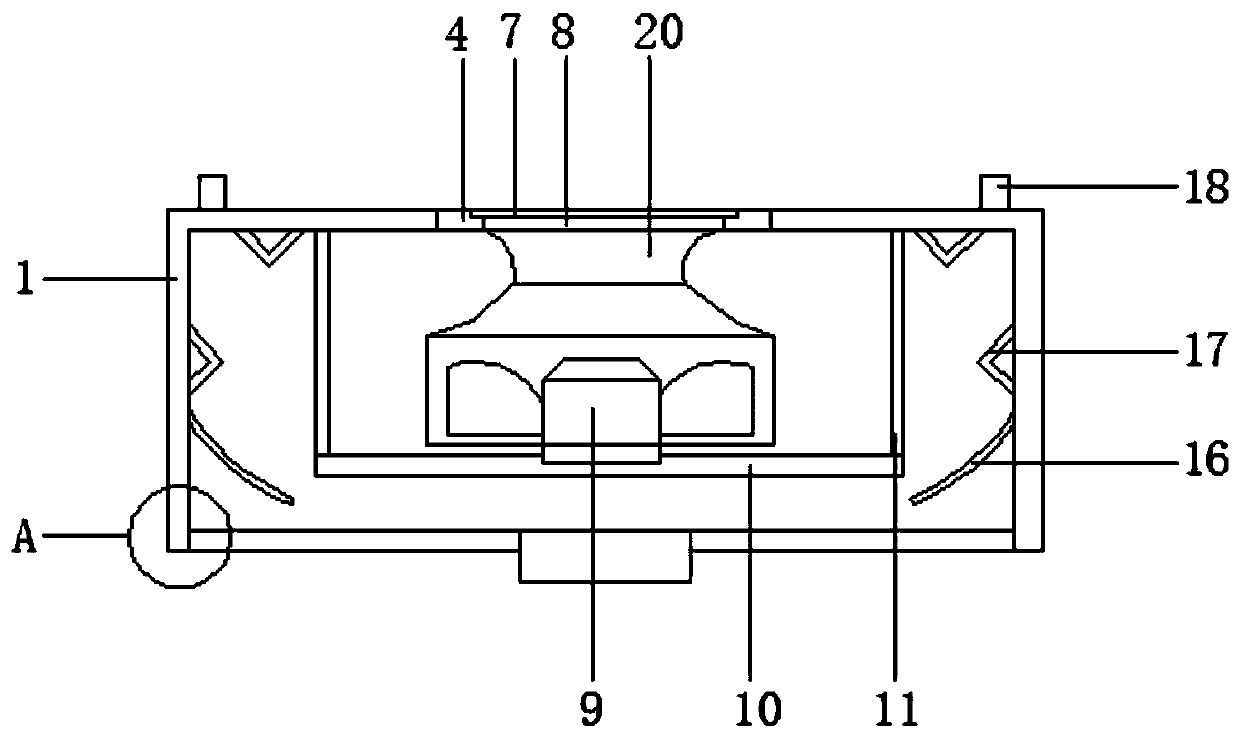

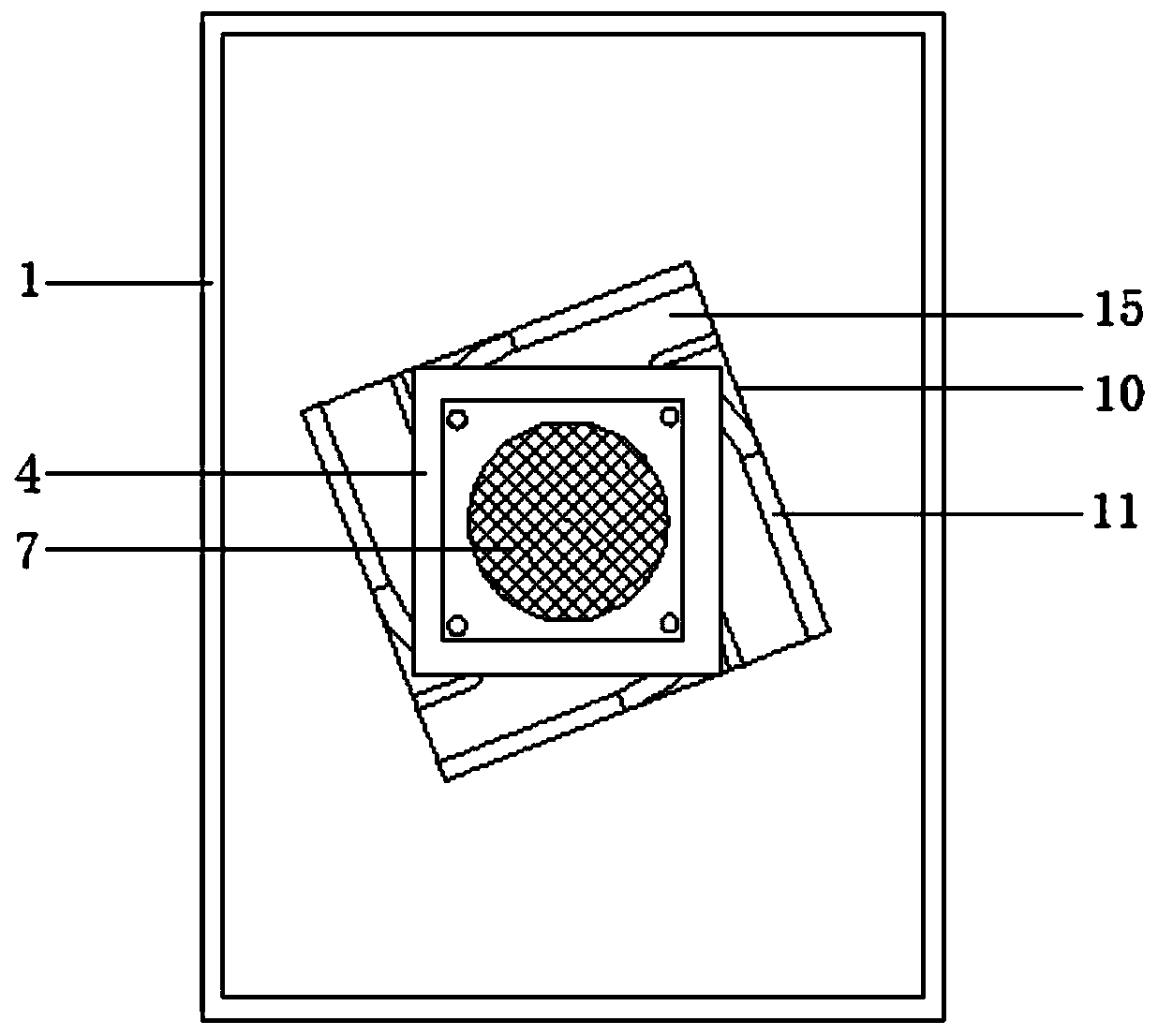

[0024] see Figure 1-Figure 5 As shown, the present invention provides a technical solution: a FFU four-air channel box structure, including an FFU box 1, a universal fixing plate 2 connected to the top side of the inner cavity of the FFU box 1, and the universal fixing plate 2 is set as a rectangular settling tank structure, and the controller 3 is installed in the universal fixed plate 2, which is convenient for installation, and the controller 3 is sunk inside the FFU box 1, which plays a good protective role and prevents the staff from touching Inverted, safe and reliable, the top center of the FFU box 1 is connected with an air inlet grille structure 4, which adopts a square opening design of 25*25cm, and the air inlet grille structure 4 includes a protective cover 5, and the protective cover 5 It is sealed and connected with the FFU box 1, and the top of the protective cover 5 is provided with an installation through groove 6, and the inside of the installation through g...

Embodiment 2

[0030] Such as figure 2 and image 3As shown, the air supply plate 16 is symmetrically connected to the bottom of the inner cavity of the FFU box 1, and the outlets of the air outlet 15 are correspondingly directed to the four corners of the FFU box 1, so that the airflow flowing out from the air outlet 1 can pass through the air supply plate 16 quickly. The guided air flow moves downward, which improves the air supply volume and air supply efficiency.

[0031] The present invention is improved in that: this kind of FFU box structure with four air ducts can form four air ducts by adopting the structural form of four downwind guide plates, reduce internal turbulence points, and make the air flow inside the box more smooth and uniform, and at the same time Simplify the box structure, facilitate assembly, and improve work efficiency. The controller 3 adopts a sunken shared cover design, which facilitates the replacement of different types of controllers in the later stage. Thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com