Method of testing wind load of 1000kV ultra-high voltage substation framework through wind tunnel experiment

A technology of wind tunnel test and substation structure, which is applied in the field of civil engineering, can solve the problems of poor calculation accuracy of wind load, etc., and achieve the effect of comprehensive and detailed steps, simple process and accurate wind tunnel test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1: The method for testing the wind load of the 1000kV UHV substation frame through the wind tunnel test of the present embodiment is carried out according to the following steps:

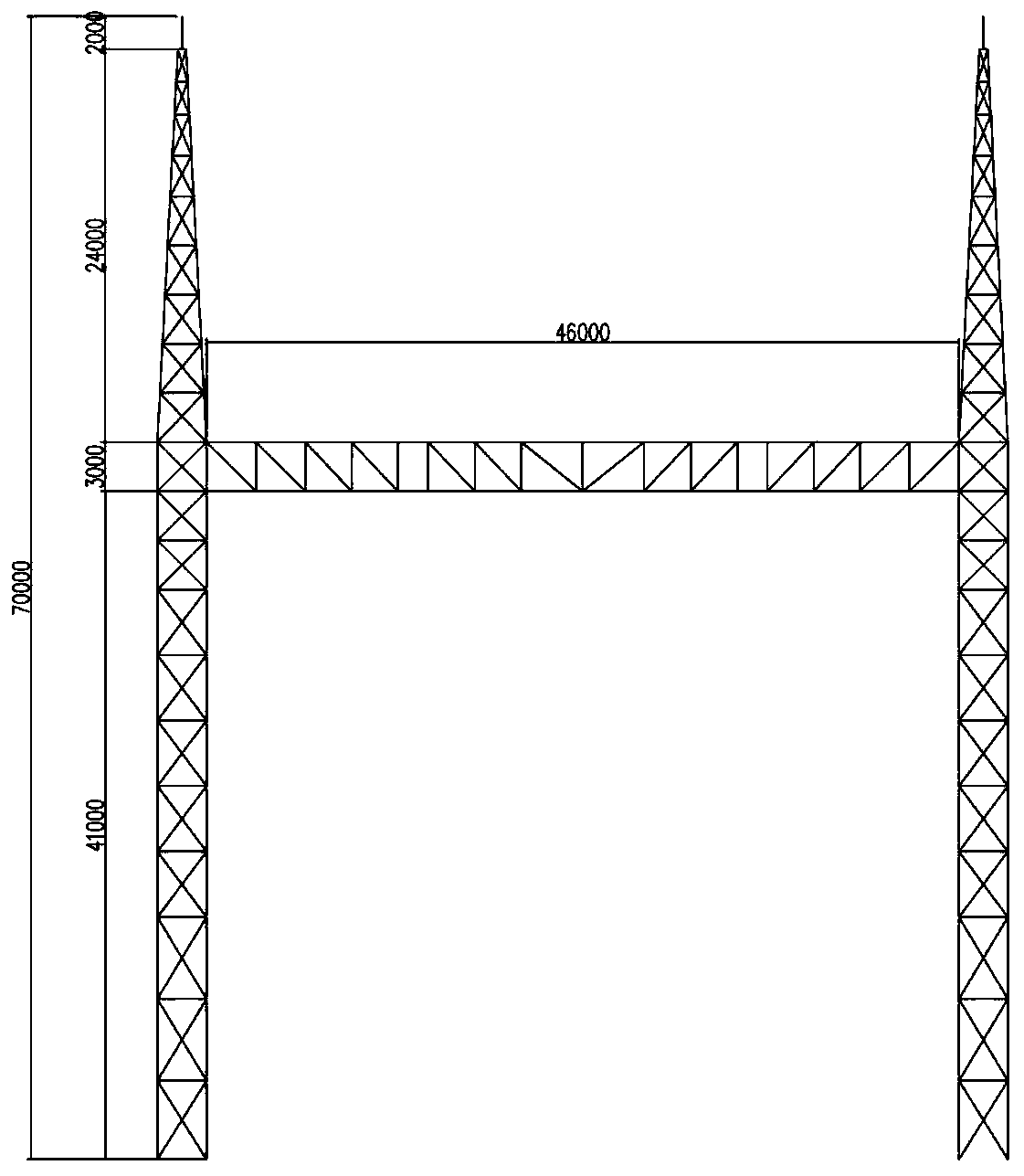

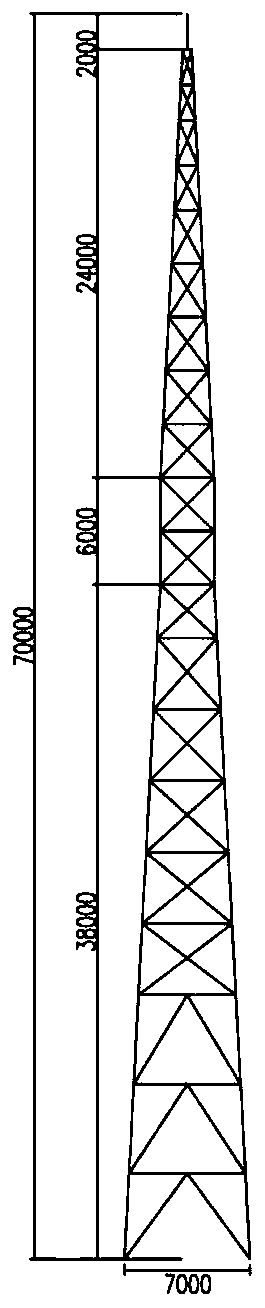

[0082] Step 1: Prepare a rigid model according to the actual shape of the 1000kV UHV substation frame. The photo of the model is as follows figure 1 As shown, the linear structure of the model is as follows figure 2 As shown, the horizontal structure is as image 3 shown. The model is made of SLA polymer photosensitive resin as raw material and 3D printing technology. The overall model is divided into five segment models: I, II, III, IV, and V; middle truncation, such as Figure 4 As shown, the segmentation diagram of the five segment models I, II, III, IV, and V is as follows Figure 5 As shown, 1 is the I-segment model, and its photo is shown in Image 6 as shown; 2 is the segment II model, and its photos are shown in Figure 7 as shown; 3 is the segment III model, and its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com