Liquor making fermentation process monitoring system

A monitoring system and fermentation process technology, applied in the field of winemaking, can solve the problems of high real-time performance, waste of labor and error rate, unfavorable industrial production of liquor, etc., and achieve the effects of simple structure, good accuracy and timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

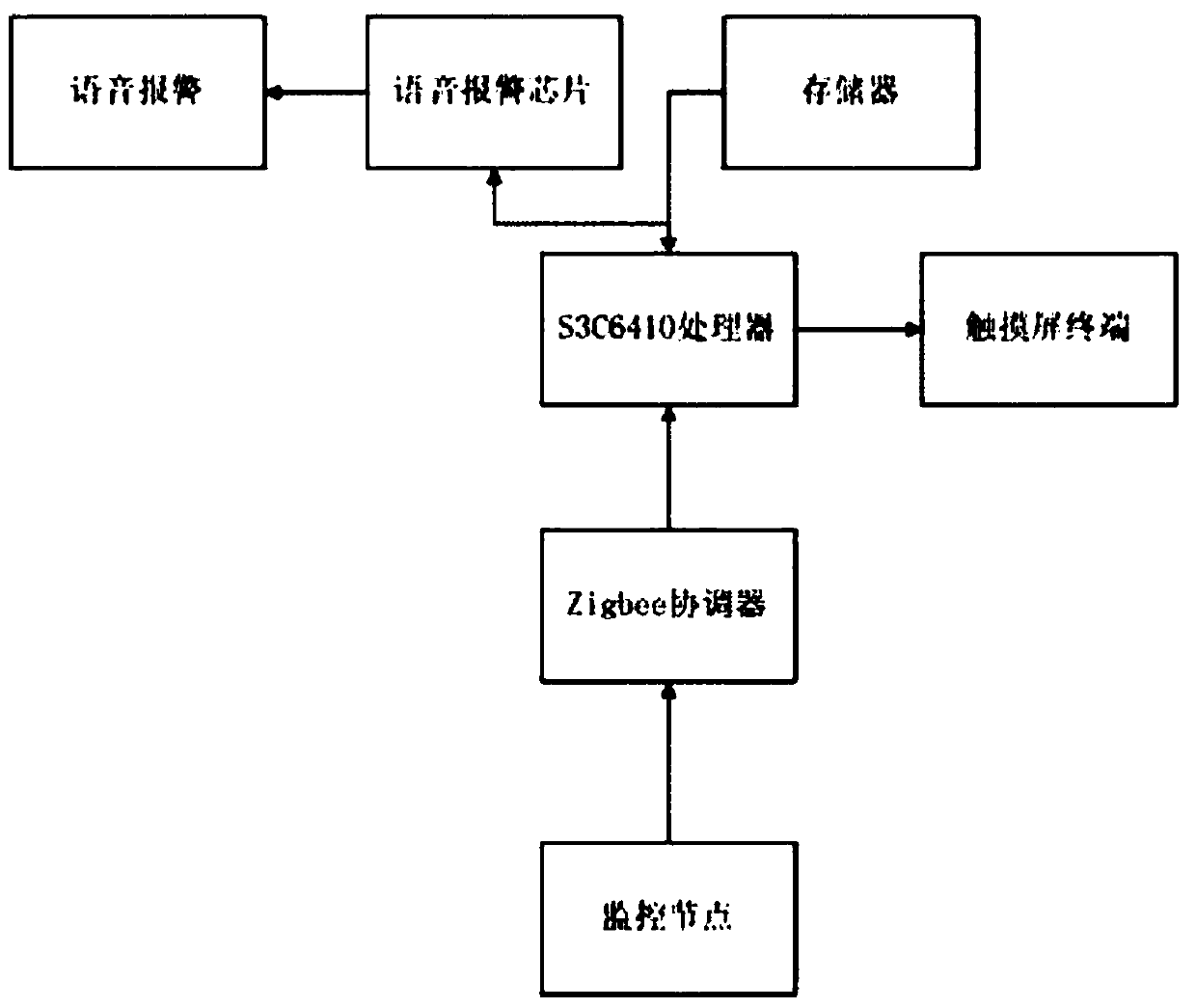

[0017] A monitoring system for the brewing and fermentation process, which includes a monitoring node, which is connected to a ZigBee coordinator through RF wireless data transmission, the ZigBee coordinator is connected to a processor through serial port communication, and the processor is connected to a voice chip and a memory wire.

[0018] The processor is also connected with the touch screen terminal through wire or wireless network.

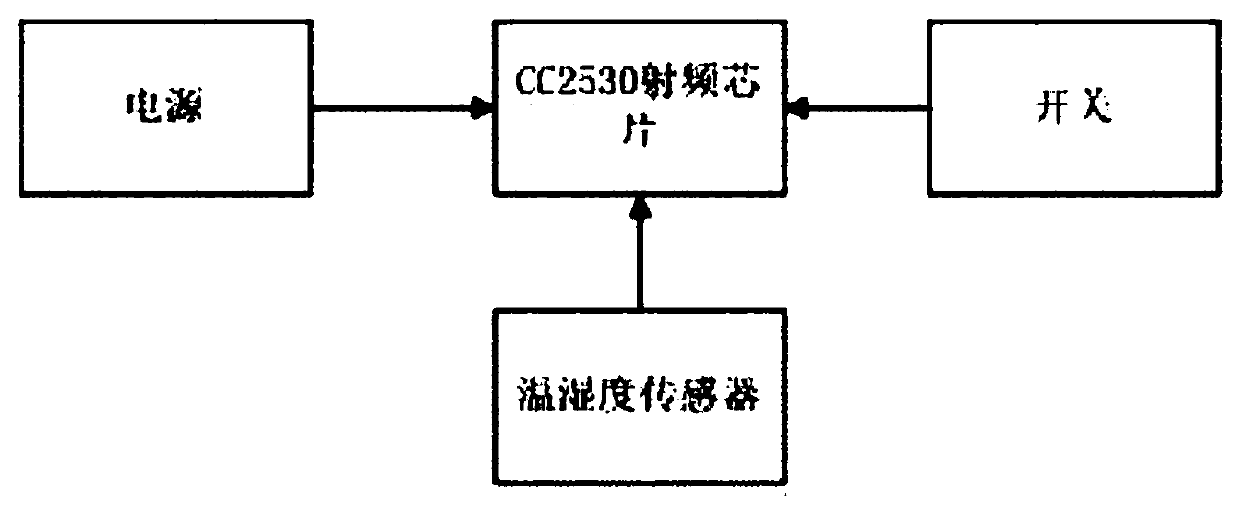

[0019] The monitoring node includes a temperature and humidity sensor, and the temperature and humidity sensor is connected with a radio frequency chip wire.

[0020] The temperature and humidity sensor is a DHT11 temperature and humidity composite sensor. DHT11 is a temperature and humidity composite sensor packaged in a 4-pin single row of pins. It has a built-in resistive humidity sensing element and an NTC temperature measuring element [2]. The temperature and humidity data collected by DHT11 are serially transmitted to the CC2530 RF ch...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap