Deep learning-based visual detection method for packing missing strips

A technology of visual detection and deep learning, applied in the field of visual detection of missing strips in boxes based on deep learning, can solve the problems of few abnormal images and difficulty in application, and achieve the effect of strong adaptability and robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

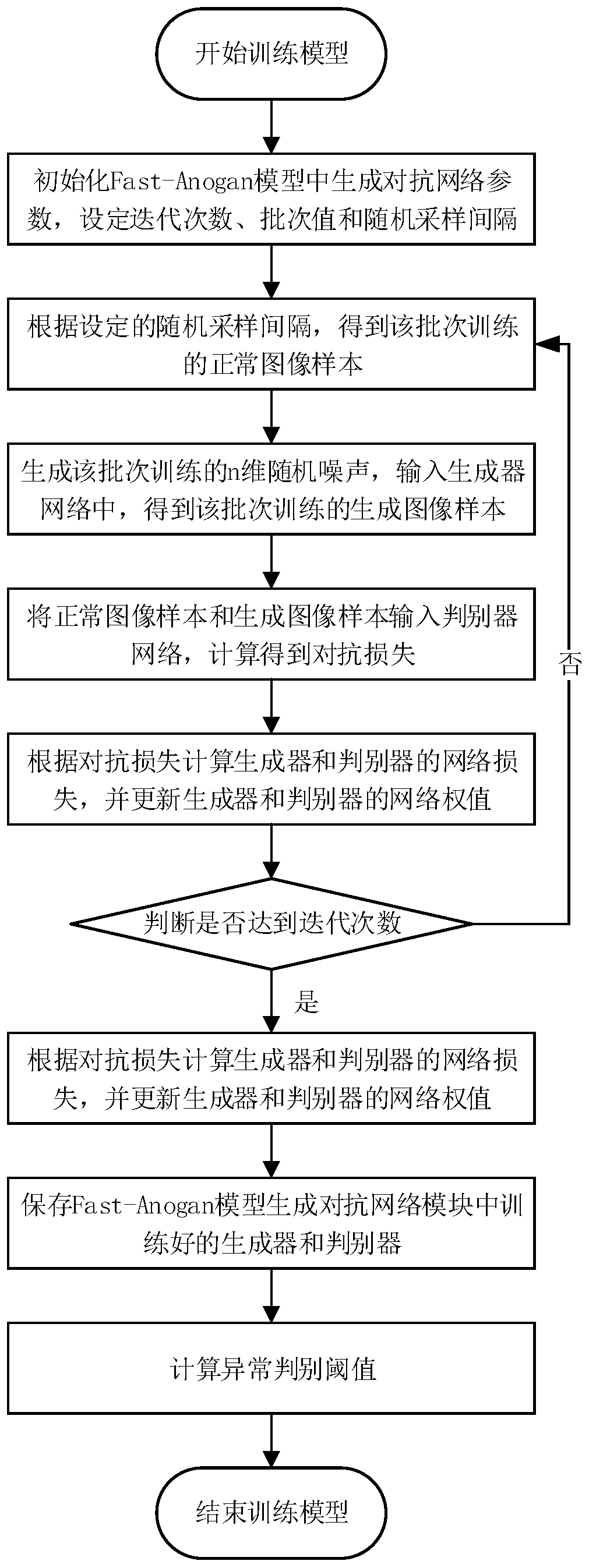

[0056] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples.

[0057] The present invention takes an image of a box-sealed box in the production of a certain brand of cigarettes in a cigarette factory as an example. The abnormal detection task requires the model detection speed to be less than 100ms, that is, more than 10 images need to be processed per second, and the detection accuracy is maintained at more than 80%. That is, the false positive rate should be less than 20%.

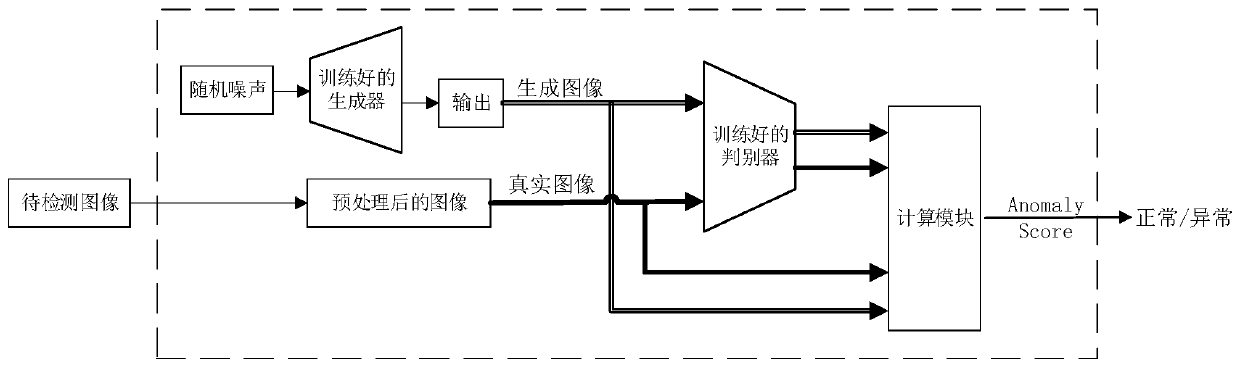

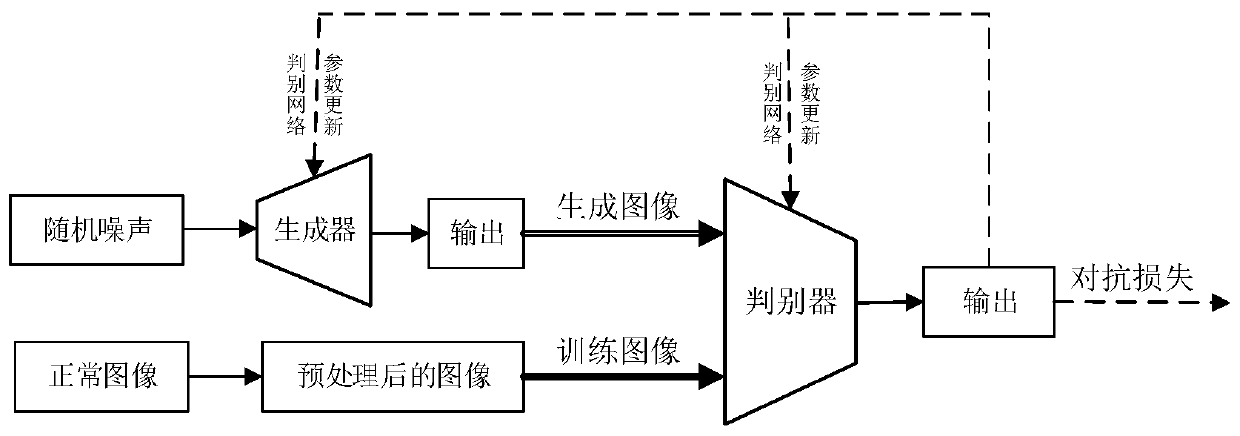

[0058] like figure 1 As shown, the present invention is a deep learning-based visual detection method for missing strips in boxes, which realizes abnormal detection of images in cigarette boxes by constructing a Fast-AnoGAN algorithm model. like figure 1 As shown, the Fast-AnoGAN anomaly detection model includes a generative adversarial network module and an anomaly score calculation module. like figure 2 As shown, the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com