Permanent-magnet motor rotor core structure

A rotor core, permanent magnet motor technology, applied in the shape/style/structure of the magnetic circuit, the rotating parts of the magnetic circuit, the magnetic circuit, etc., can solve the high risk of rotor fragmentation, increase the difficulty of punching, increase the reluctance, etc. problems, to reduce the risk of high temperature demagnetization, weaken the magnetic flux leakage phenomenon, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

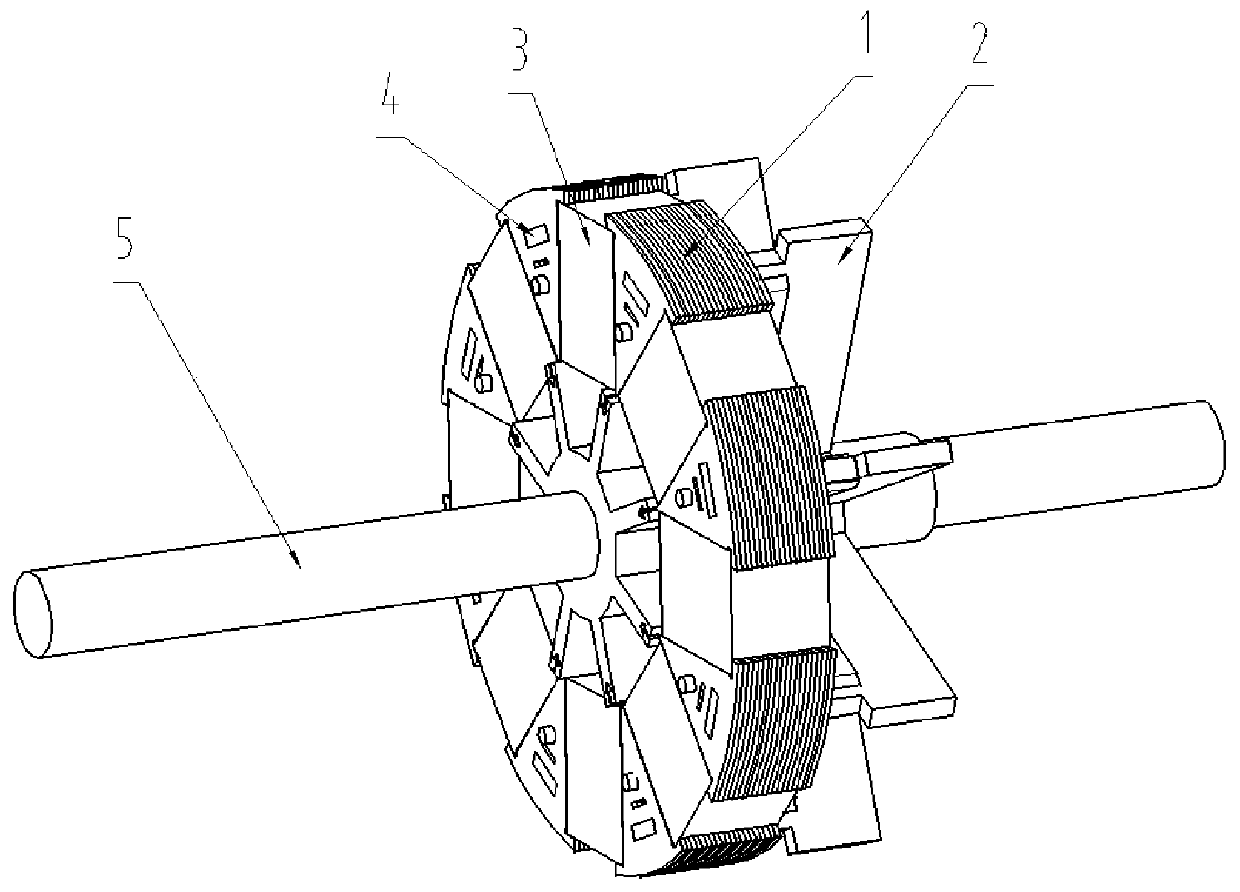

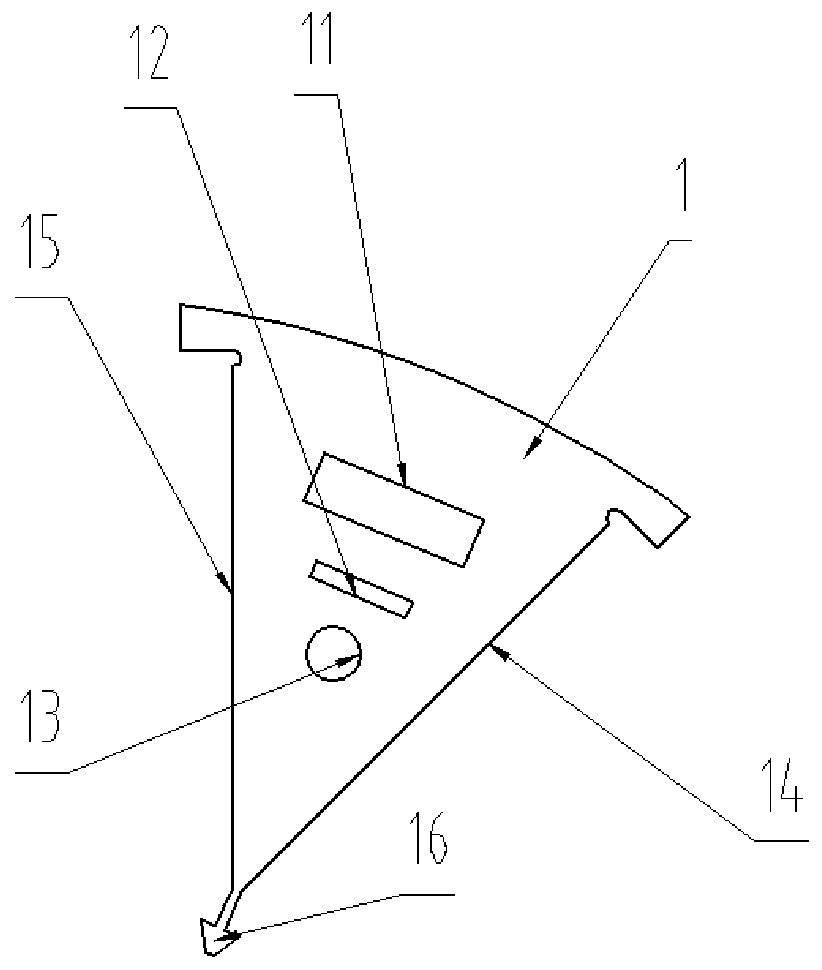

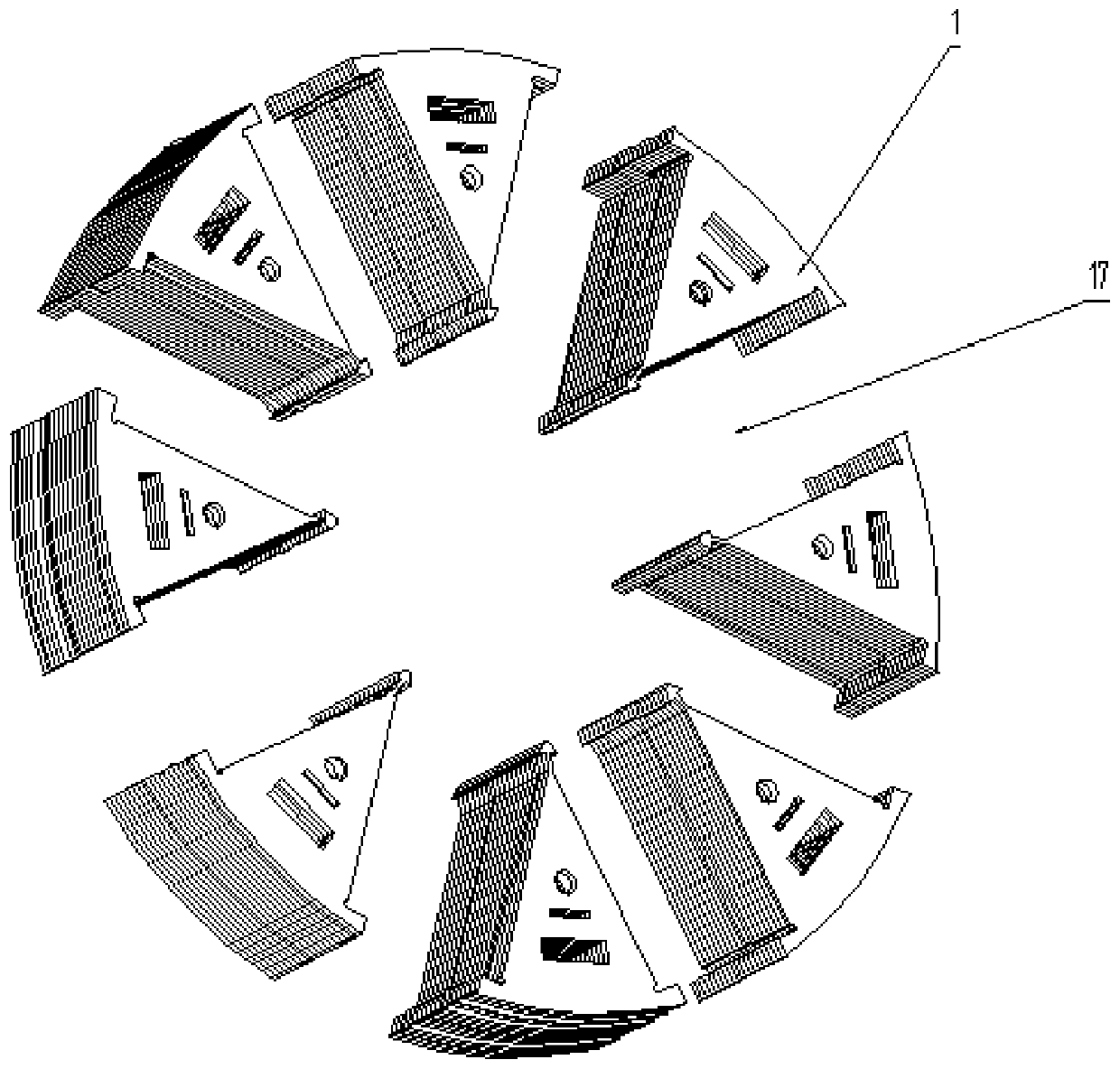

[0022] figure 1 What is shown is a structural schematic diagram of the present invention, which includes a rotor core 1 , a rotor core support 2 , a second permanent magnet group 3 , a first permanent magnet group 4 and a rotor shaft 5 . The rotor core 1 consists of figure 2 The rotor punches shown are stacked through riveting slots 12 . The rotor punch is provided with a first permanent magnet slot 11 , a positioning slot 13 , a riveting slot 12 and a reinforcing sheet 16 . The first permanent magnet slot 11, the positioning slot 13, the riveting slot 12 and the reinforcement piece 16 are radially distributed on the rotor punch; the rotor punch is laminated into the rotor core 1 by positioning the slot 13 and the riveting slot 12; The rotor core support 2 includes evenly distributed impellers 20 , and the impellers are provided with cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com