Pressure solidification forming device and method for suspension manufacturing

A solidification forming and pressure technology, applied in the field of liquid metal solidification and forming, can solve the problems of low temperature gradient, poor service performance, affecting the solidification structure characteristics of materials, etc., and achieve the effect of avoiding internal stress and benefiting protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

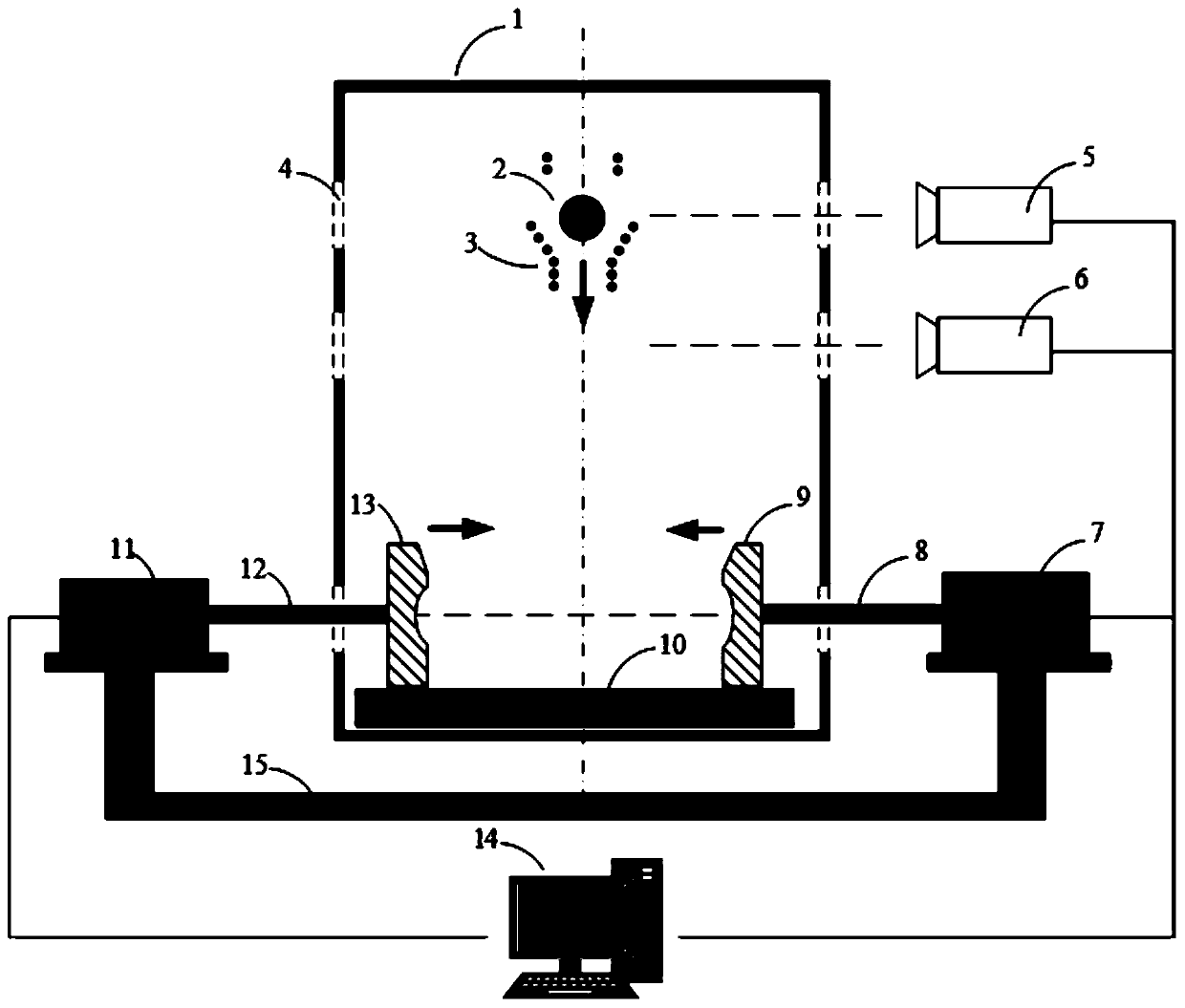

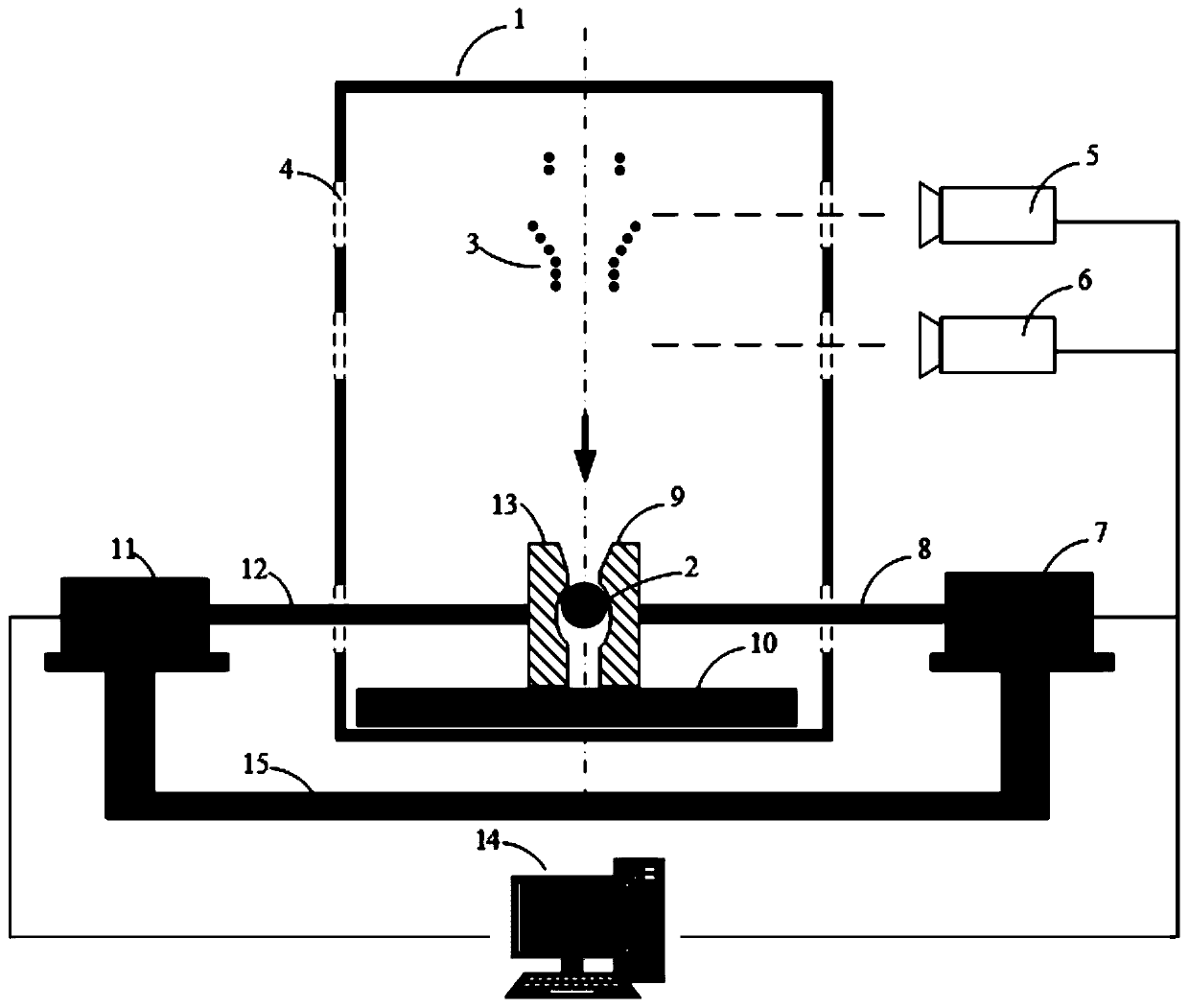

[0074] By using the pressure solidification molding device and method for suspension manufacturing provided by the present invention, the spherical casting mold of Al droplets under the condition of electromagnetic suspension can be obtained.

[0075] (1) Selection of mold and mold movement mode: the experimental requirement is to design a spherical casting with r=20mm, design a spherical mold that can be die-cast, and choose one-sided mold to fix,

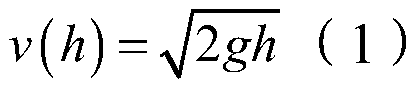

[0076] (2) Calculation of falling time: In a specific device, the radius of the melt is 0.023m, and the vertical distance between the first detector 5 and the axis of the mold is h 1 =0.5m, the vertical distance between the second detector 6 and the axis of the mold is h 2 =0.35m, then the time passing through the second detector is about t 1 =0.173s, the time required for falling to the mold center is 0.316s.

[0077] (3) Determine the moment to trigger the mold movement: unilateral mold movement. From the formula 7, it can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com