A kind of drilling tool assembly for horizontal drilling and coring in underground coal mine and its application method

A technology of horizontal drilling and core drilling, applied in the direction of drill pipe, drill pipe, drill bit, etc., can solve the problem of small annular gap of positive circulation channel, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

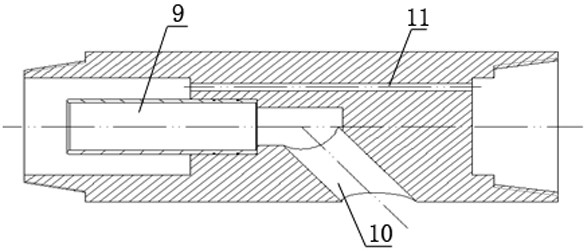

[0023] The present invention will be further described in conjunction with the accompanying drawings.

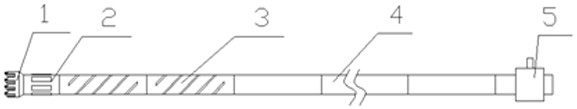

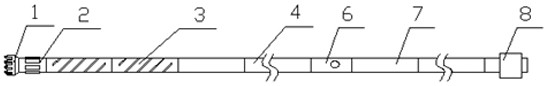

[0024] Embodiments of the present invention provide a method for coring horizontal boreholes in underground coal mines and a drilling tool assembly, including two sets of drilling tool assemblies I and II. , using the hydraulic reverse circulation drilling process to implement continuous coring. When a certain depth is reached, there is no need to lift the drill, remove the reverse circulation faucet 5, add the conversion nipple II6, single-wall drill pipe 7, and faucet 8, and replace the above The drilling tool I is converted into the aforementioned drilling tool II, and the core is taken by adopting the positive circulation drilling technology.

[0025] Among them, the drilling tool I includes a φ98mm coring drill bit 1, a φ89mm core length controlled pup joint I2, a φ89mm double-walled drill pipe with reverse helical groove 3, a φ89mm double-walled drill pipe 4, and a rev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com