Continuous stirred reactor system control method based on Hammerstein model

A technology of a reactor system and a control method, which is applied in the field of continuous stirring reactor system control, can solve the problems of a large amount of calculation, a complex control law, an increase in the complexity of the calculation and the difficulty of parameter estimation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

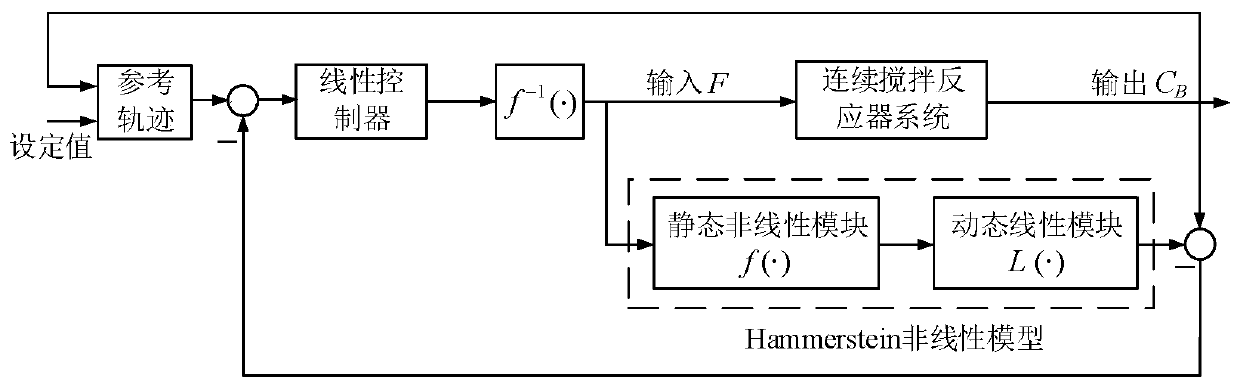

[0053] The present invention will now be described in detail with reference to the drawings. This figure is a simplified schematic diagram, which only illustrates the basic structure of the present invention in a schematic way, so it only shows the structure related to the present invention.

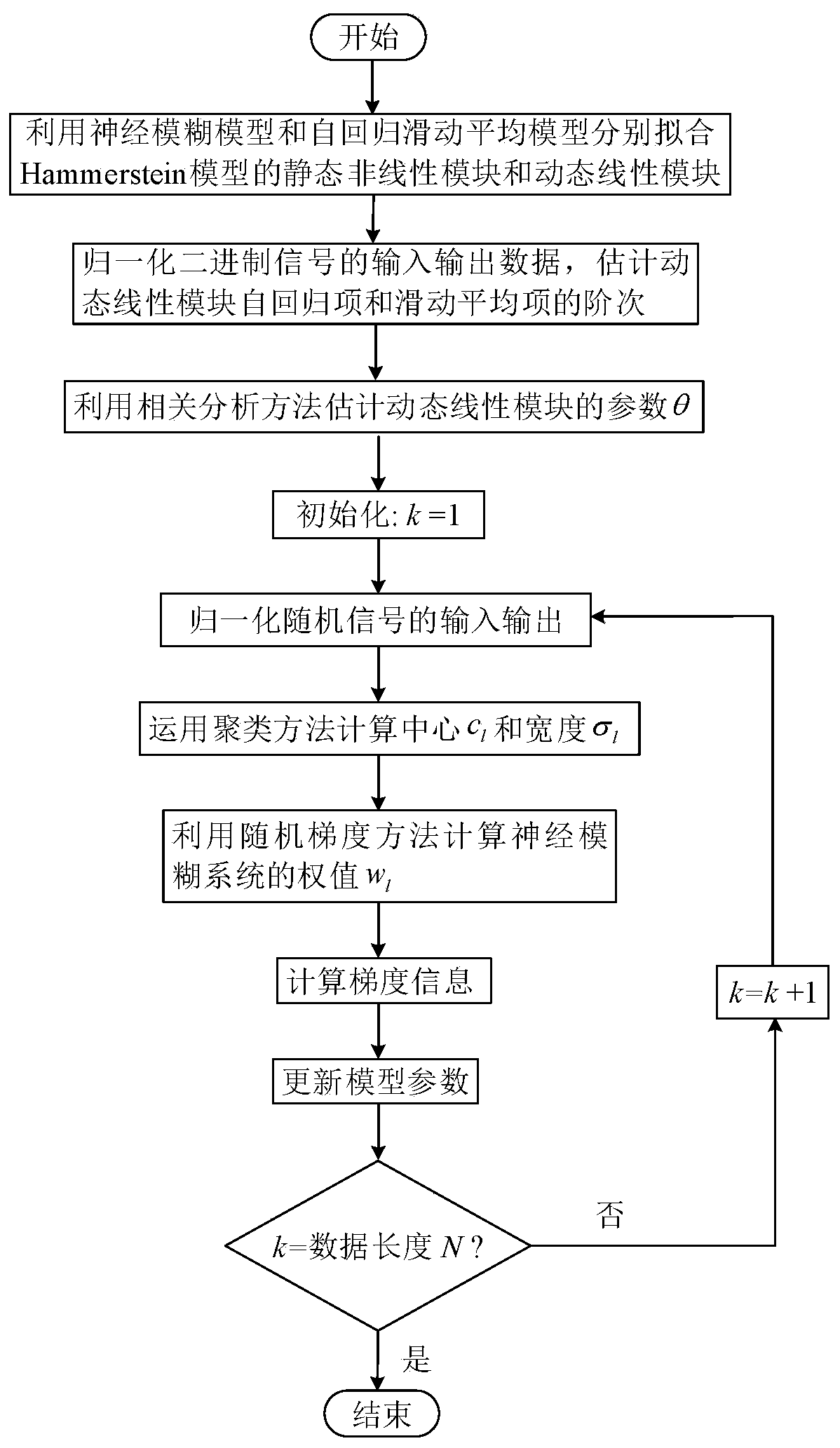

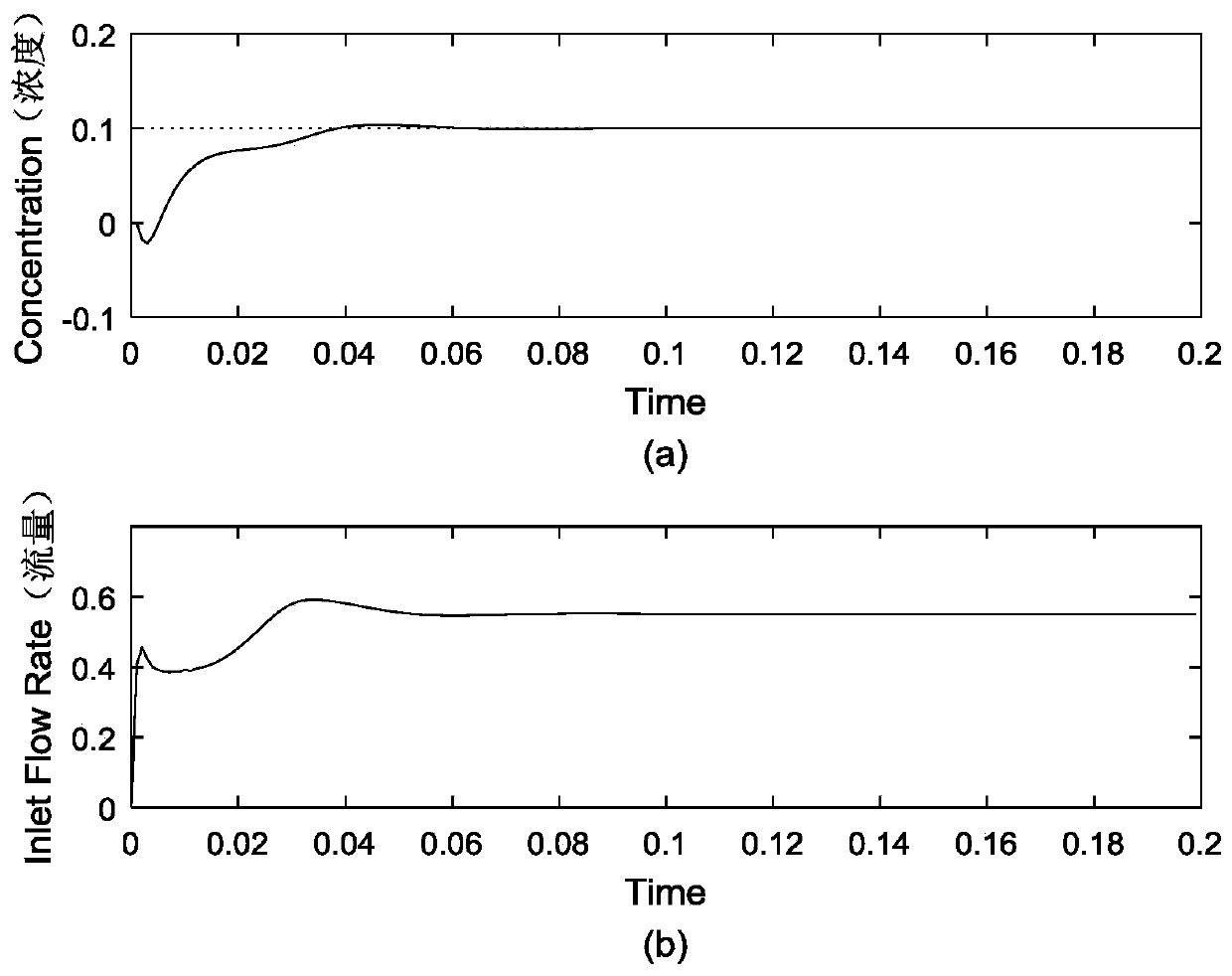

[0054] Such as figure 1 As shown, a continuous stirred reactor system control method based on the Hammerstein model includes the following steps:

[0055] First, in a continuous stirred reactor system, F 0 = 34.3 (L / h) and C B0 =1.12 (mol / L) are the steady-state values corresponding to the reaction at a steady-state operating point, where F 0 Indicates the steady state value of flow, C B0 Indicates the steady-state value of the concentration of reactant B. The present invention uses a composite signal composed of a binary signal and a random signal as the input of the system. When using the Hammerstein model to establish a high-precision mathematical model of the continuous stirred reactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com