Cement finished product specific surface area prediction method and system

A technology of specific surface area and cement products, applied in neural learning methods, measuring devices, biological neural network models, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

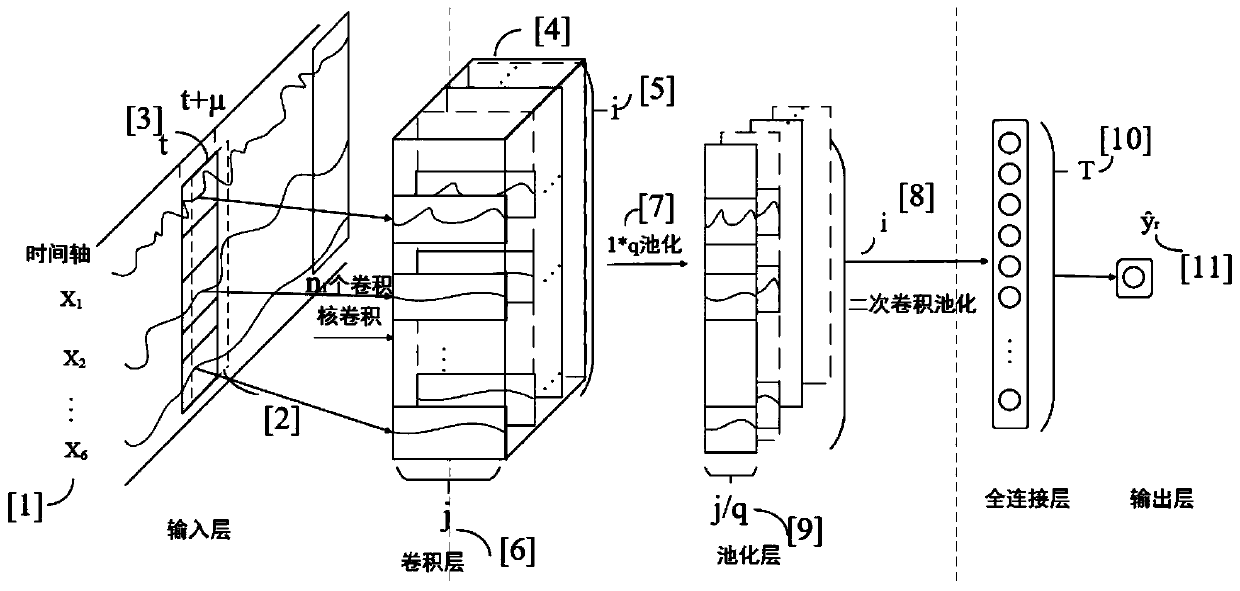

[0113] The method for predicting the specific surface area of cement products in this embodiment first selects the experimental value of the specific surface area of the cement product at the previous moment and the particle size distribution value of the cement product measured by the particle size analyzer from the database of the cement grinding system, respectively AB particle size45um, AB particle size>60um, AB particle size>80um, a total of 6 input variables. Combining the technology of sliding window time series with convolutional neural network, and using back propagation technology to fine-tune the weights, a well-trained specific surface area prediction model is established. The specific flow model diagram is as follows figure 2 shown.

[0114] figure 2 Schematic diagram of the structure of the specific surface area prediction model trained for Example 2 of the present invention.

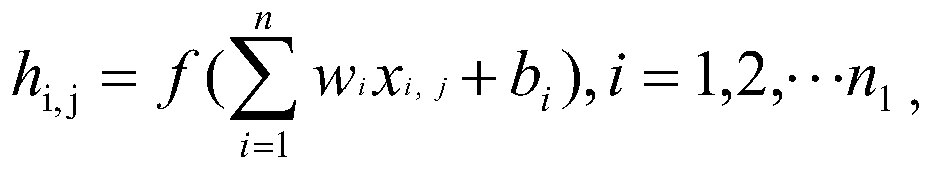

[0115] see figure 2 , the method for predicting the specific surface area of ...

Embodiment 3

[0155] This embodiment provides a system for predicting the specific surface area of cement products, including:

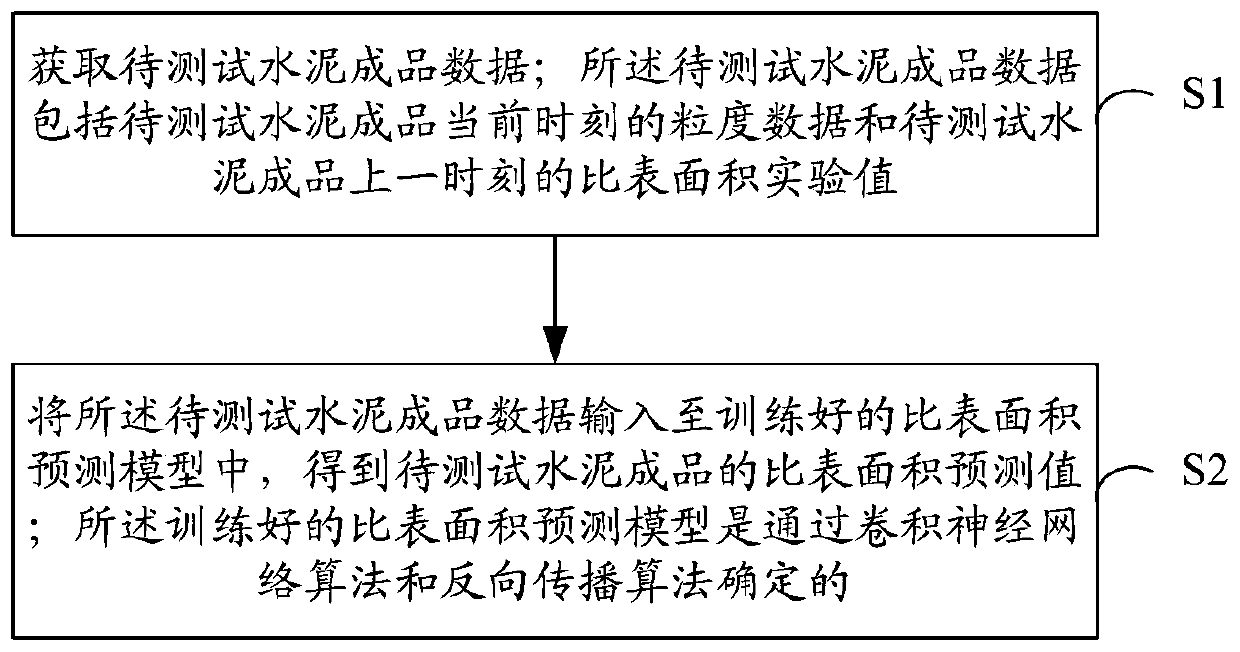

[0156] The data acquisition module is used to obtain the data of the finished cement product to be tested; the data of the finished cement product to be tested includes the particle size data of the finished cement product to be tested at the current moment and the experimental value of the specific surface area of the finished cement product to be tested at a previous moment; the particle size data includes multiple particle size values; each said particle size value belongs to a different particle size range.

[0157] Prediction module for inputting the data of the finished cement product to be tested into the trained specific surface area prediction model to obtain the predicted value of the specific surface area of the finished cement product to be tested; the trained specific surface area prediction model is obtained through a convolutional neural networ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com