Wound rotor or stator and manufacturing method

A technology of winding rotors and stators, which is applied in the field of manufacturing tooth-shaped winding stators, and can solve the problems of time-consuming winding operations and obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

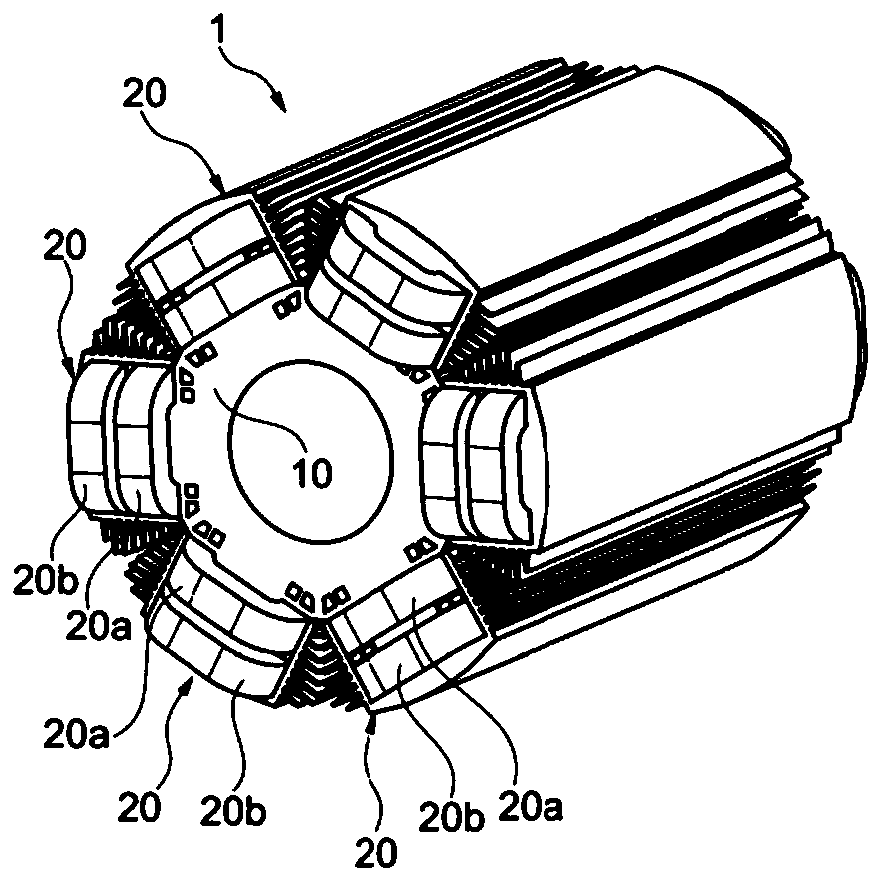

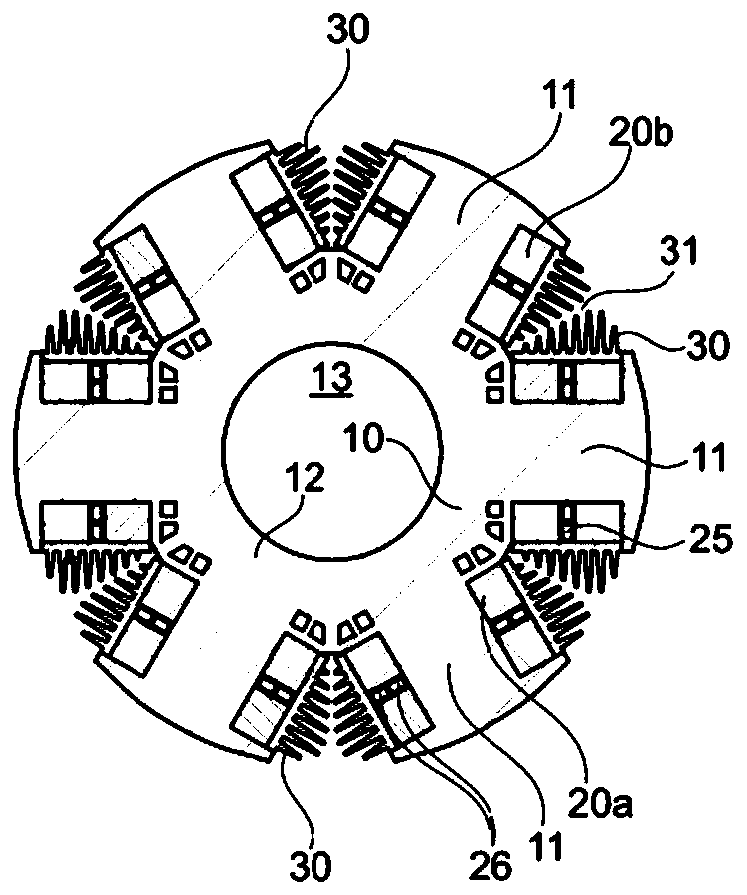

[0034] The rotor 1 according to the invention shown in the figures comprises a magnetic core 10 which is called an armature and which may be formed by a bundle of superimposed magnetic plates.

[0035] This magnetic core 10 comprises teeth 11 connected at their bases by an annular part 12 provided with a central hole 13 for mounting a shaft, not shown.

[0036] In the example considered, the rotor 1 has six poles and comprises six teeth 11 .

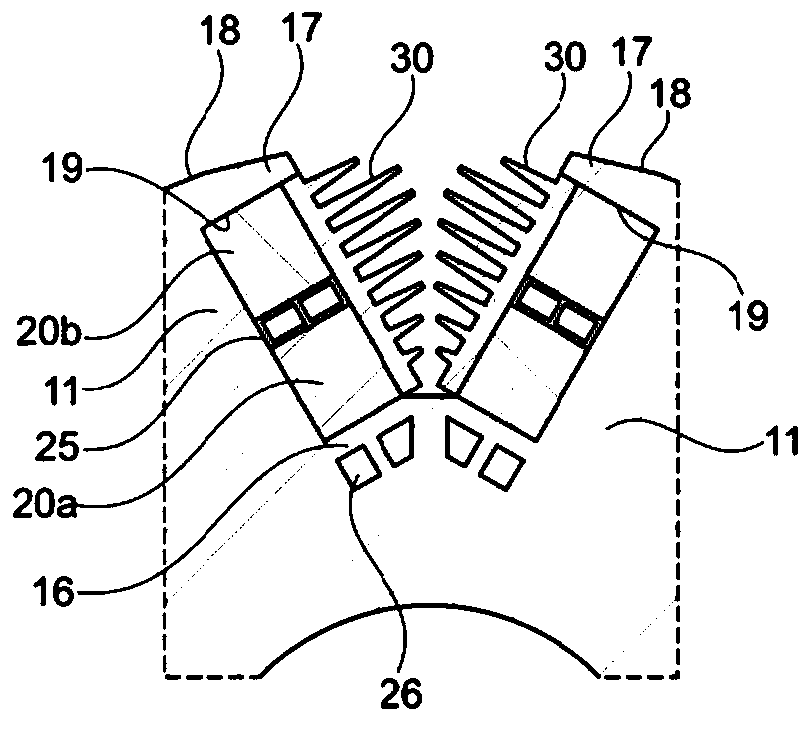

[0037] Vent channels 14 may be made between the teeth 11 as shown. These channels 14 may be formed between the annular part 12 and a partition 16 oriented at right angles to the longitudinal axis X of the adjacent tooth 11 .

[0038] In the example shown, each tooth 11 has two channels 14 on each side of its base, it being understood that other arrangements without ventilation channels, or with a different number of channels, are possible.

[0039] Each tooth 11 has at its radially outermost end two pole shoes 17 , also called pole tip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com