Phase change control device and control method of variable-capacitance linear electrostatic motor

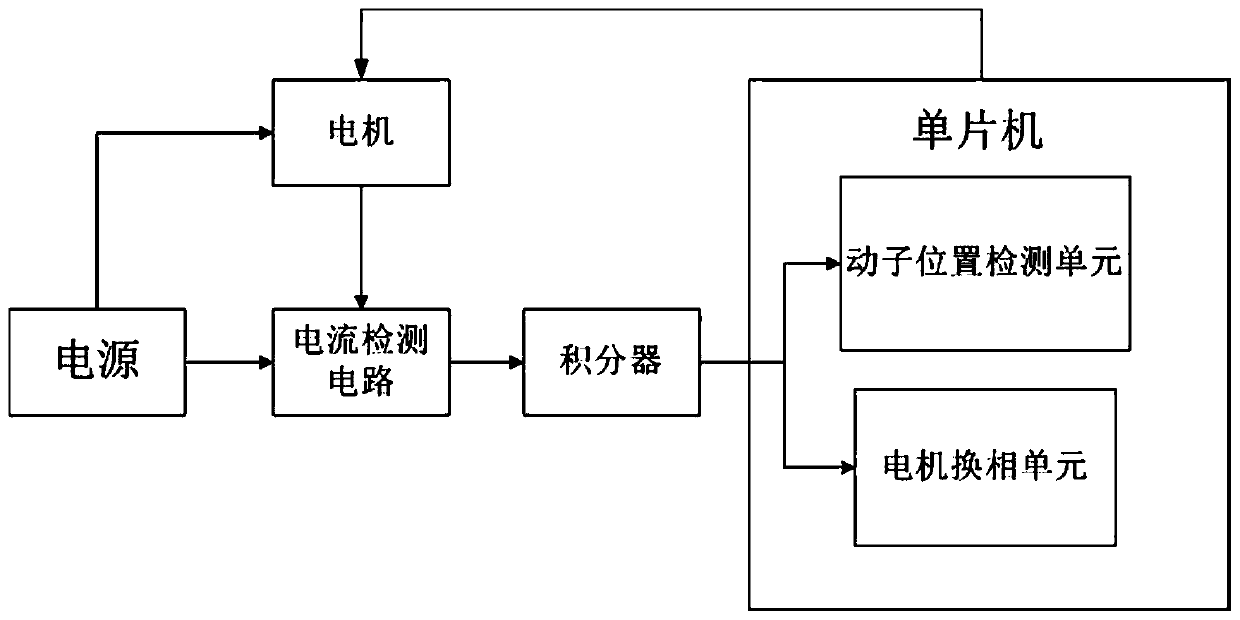

A variable capacitance, phase control technology, applied in electrostatic motors, electrostatic generators/motors, generators/motors, etc., can solve problems such as slow motion speed, motor out-of-step, high-efficiency motor operation and long-term stable operation difficulties, etc. To solve the effect of running too slow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions and beneficial effects of the present invention will be described in detail below in conjunction with the accompanying drawings.

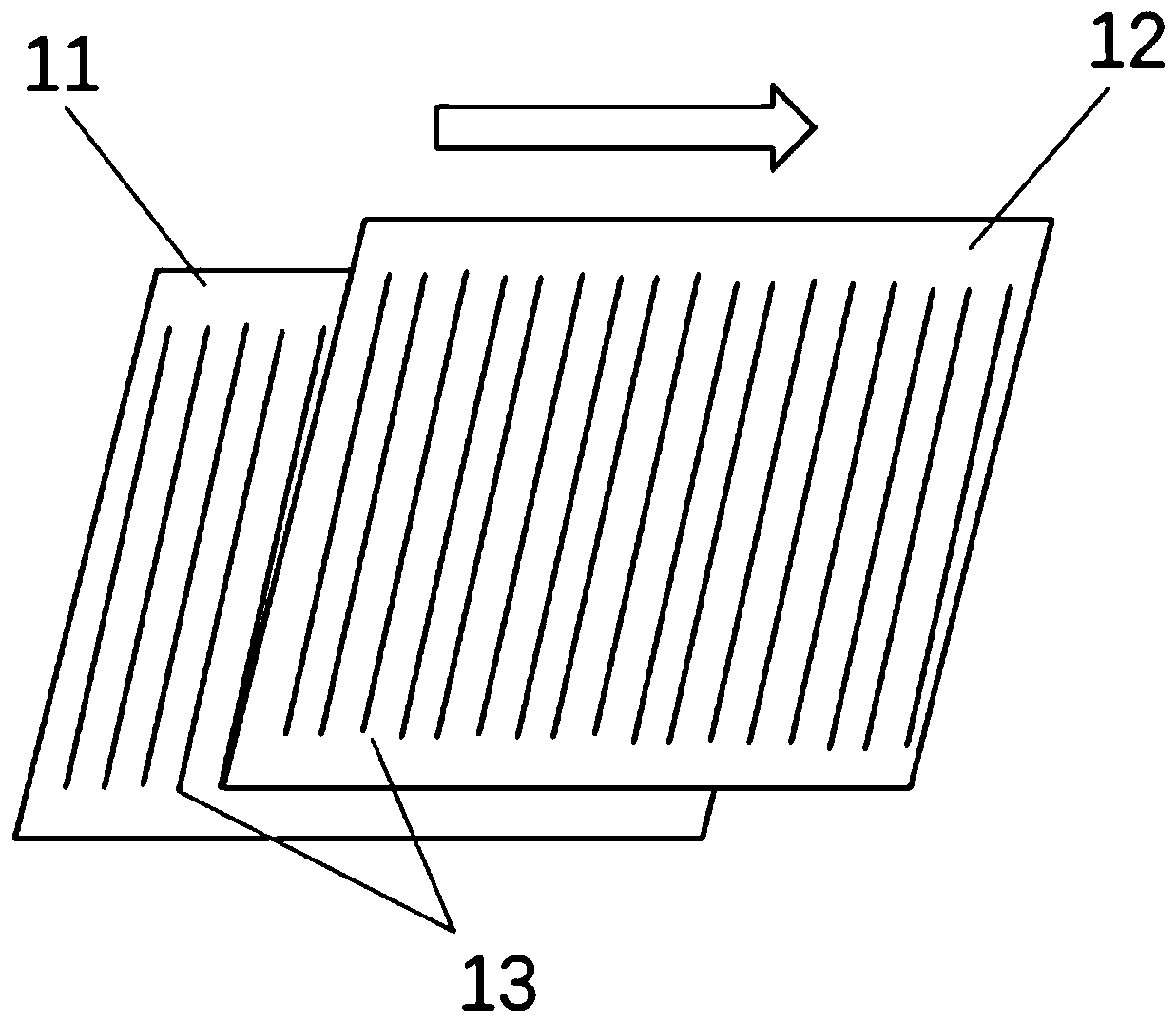

[0024] Such as figure 1 As shown, the variable capacitance linear electrostatic motor used in the present invention is composed of a pair of flexible films 11 and 12, which are used as the mover and the stator respectively. Electrodes 13 are neatly arranged on each film to accumulate charges. The potential difference between the upper and lower plates leads to electrostatic repulsion between the upper and lower films. The normal component of the electrostatic repulsion acts to reduce the friction between the stator and the mover. The tangential component of the electrostatic repulsion pushes the slider along the surface of the stator. There are micron-level gaps between the stator and the mover and between the electrodes.

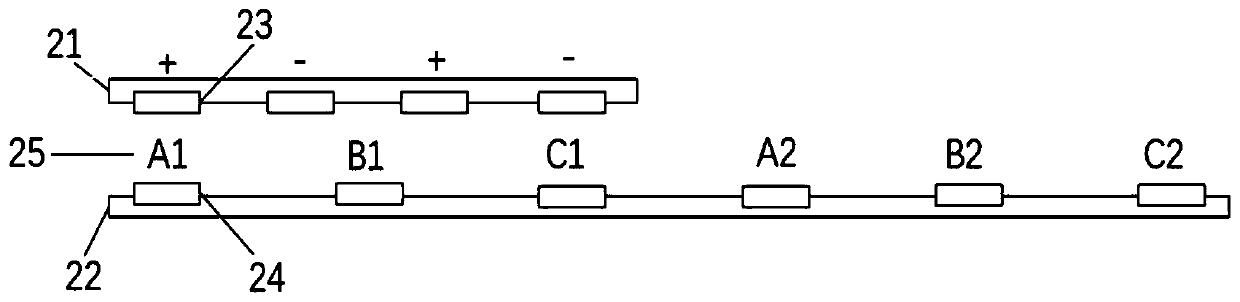

[0025] Such as figure 2 As shown, in order to make the electrostatic motor run, the films 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com