Preparation process for high-purity pralatrexate intermediate

A preparation technology of pralatrexate, which is applied in the field of preparation technology of high-purity pralatrexate intermediates, can solve the problems of high production cost, and achieve the effects of simple structure, accelerated cooling, and improved automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

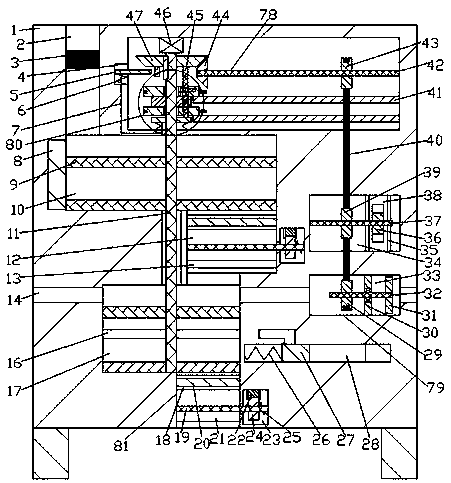

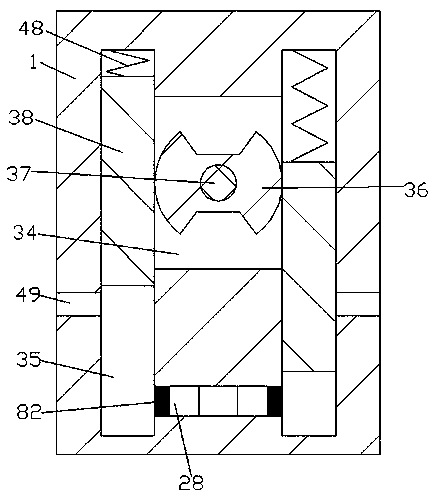

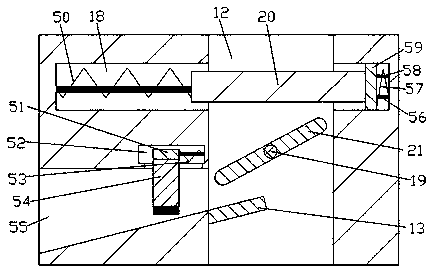

[0017] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0018] combined with Figure 1-5 The mechanical structure diagram of the preparation process of a high-purity pralatrexate intermediate mainly includes a purification box 1, and a drive chamber 61 is provided in the purification box 1, and a motor 46 and a motor 46 are arranged in the drive chamber 61. The motor 46 is connected to the drive shaft 11, and the purification box 1 is provided with a driving mechanism 78 that provides power for the operation of the device. The purification box 1 is also provided with a dissolution chamber 10 and a crystallization chamber 17. The dissolution chamber 10 and the lower end wall of the crystallization chamber 17 are provided with a filter mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com