Stirring tank with intelligent heating function for production of special wax

An intelligent heating and stirring tank technology, applied in mixers with rotating stirring devices, mixer accessories, dissolution and other directions, can solve the problems of rapid heat loss, affecting product quality, uneven stirring, etc., to achieve convenient use and improve heat preservation. effect, the effect of improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

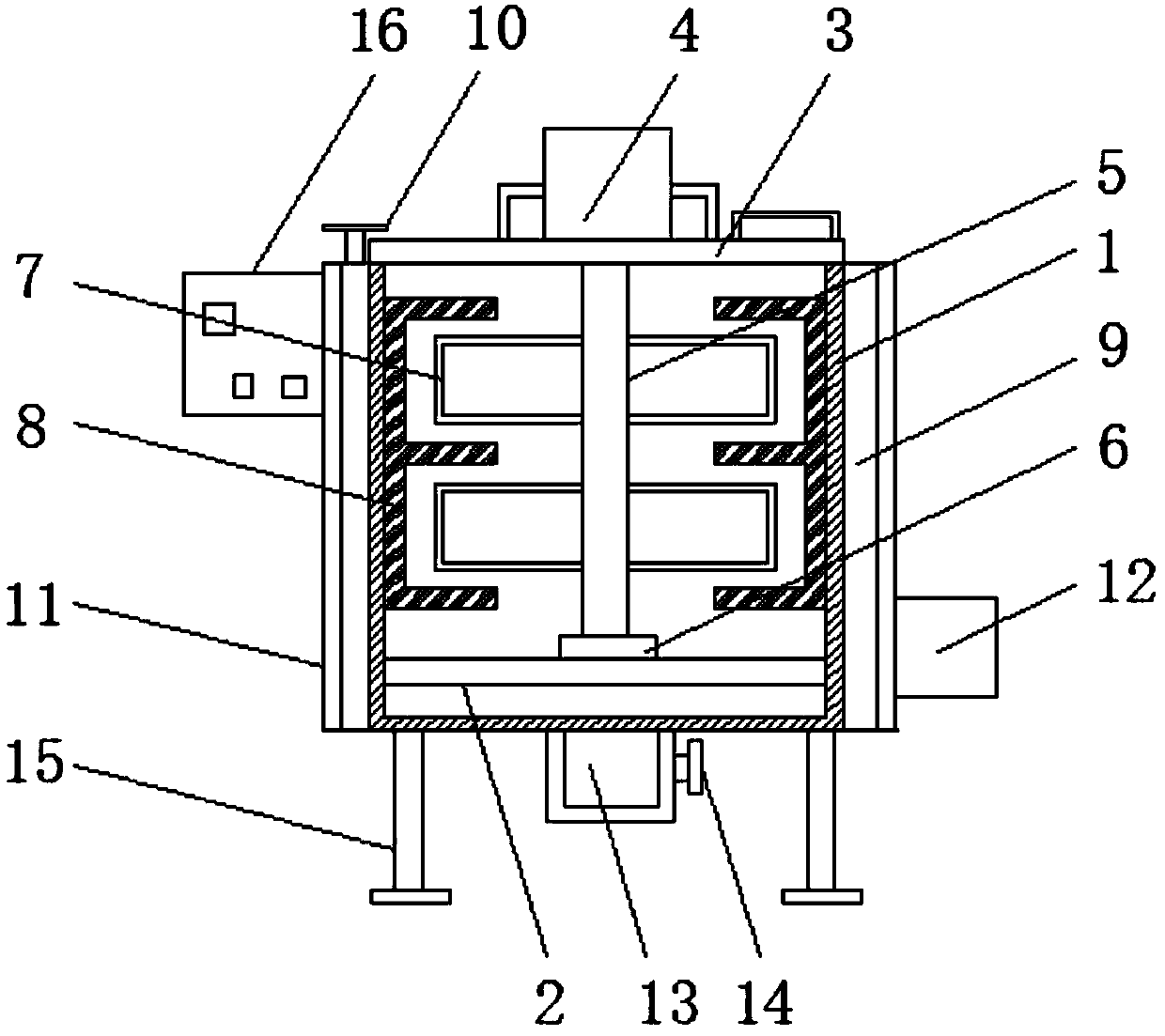

[0016] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

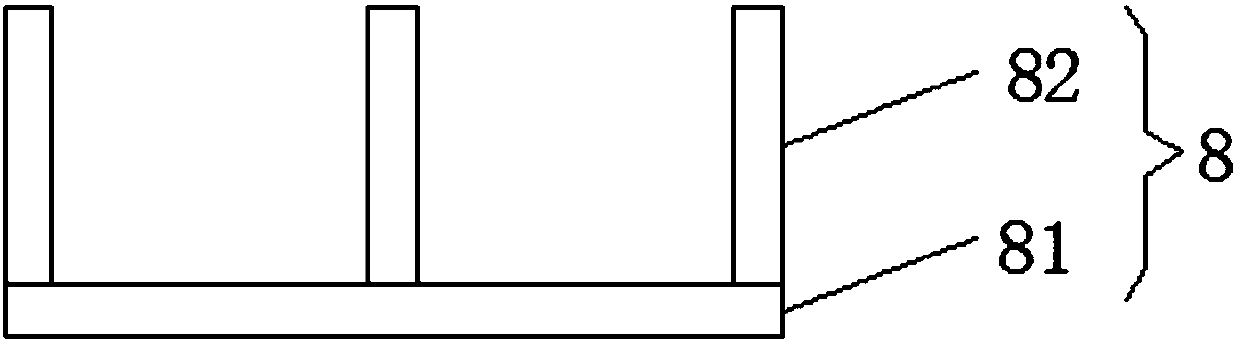

[0017] like Figure 1-2 As shown, a stirring tank with intelligent heating for special wax production includes a stirring tank body 1, and a filter plate 2 is arranged at the bottom of the inner cavity of the stirring tank body 1, which is beneficial to filtering and stirring the processed special wax. The tank cover 3 is installed on the top of the tank body 1, and the top of the tank cover 3 is provided with a motor 4, and the motor 4 is installed on the stirring tank body 1 through a fixed frame, and the output end of the motor 4 is installed with a stirring shaft 5, which is far away from the motor 4 One end of the shaft extends to the inner cavity of the mixing tank body 1 and the bearing 6 is installed, and the bearing 6 is fixed on the filter plate 2, the stirring paddle 7 is installed on the left and right sides of the stirring shaft 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com