Gear-shifting method for electric drive system

A technology of an electric drive system and a shifting method, which is applied to electric power devices, motor vehicles, power devices, etc., and can solve problems such as motors not being able to decelerate vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

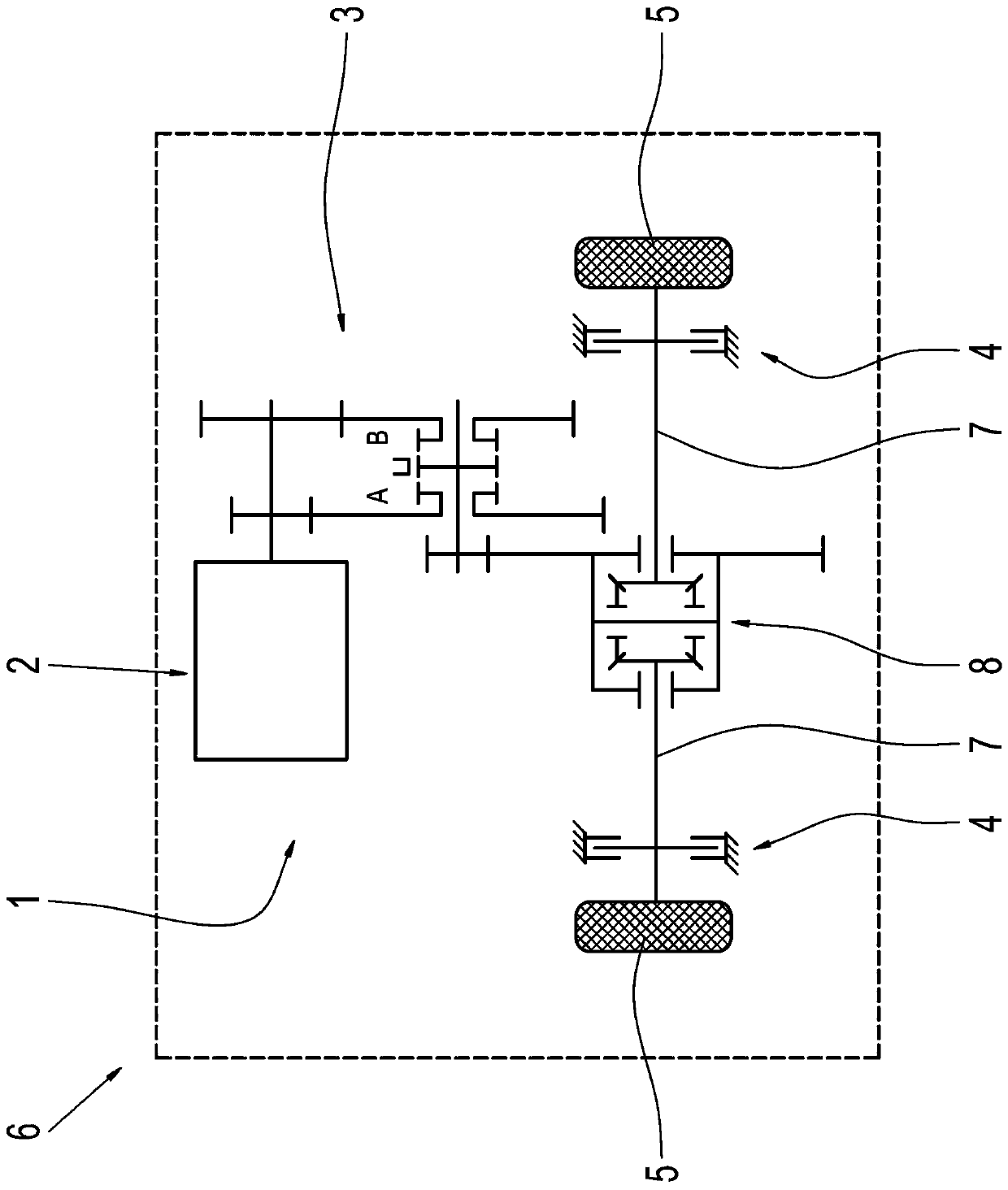

[0029] figure 1 A portion of an electric vehicle 6 is shown. The electric vehicle 6 has an electric drive system 1 with an electric machine 2 , a gearbox 3 and a brake 4 for braking wheels 5 . The electric motor 2 is drive-connected to the gearbox 3 , wherein the gearbox 3 is downstream of the electric motor 2 in terms of drive. exist figure 1 In the embodiment shown, the brake 4 is arranged on a shaft 7 drivable by the electric motor 2 . The shifting method according to the invention also functions when the brake 4 is arranged on another shaft which cannot be driven via the brake 4 .

[0030] The gearbox 3 includes a differential gearbox 8 via which the electric machine 2 can be drive-connected to the wheels 5 . Wheel 5 is drive-connected to shaft 7 . In this case, a respective brake 4 is assigned to each wheel 5 .

[0031]Transmission 3 is a 2-speed transmission with two spur gear stages. In order to realize the two gears, the gearbox 3 has a first shifting element A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com