Device and method for testing radial permeability of concrete gas

A gas permeation and testing device technology, applied in measuring devices, liquid tightness measurement using liquid/vacuum degree, permeability/surface area analysis, etc., to achieve fast and accurate testing, simple device structure, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

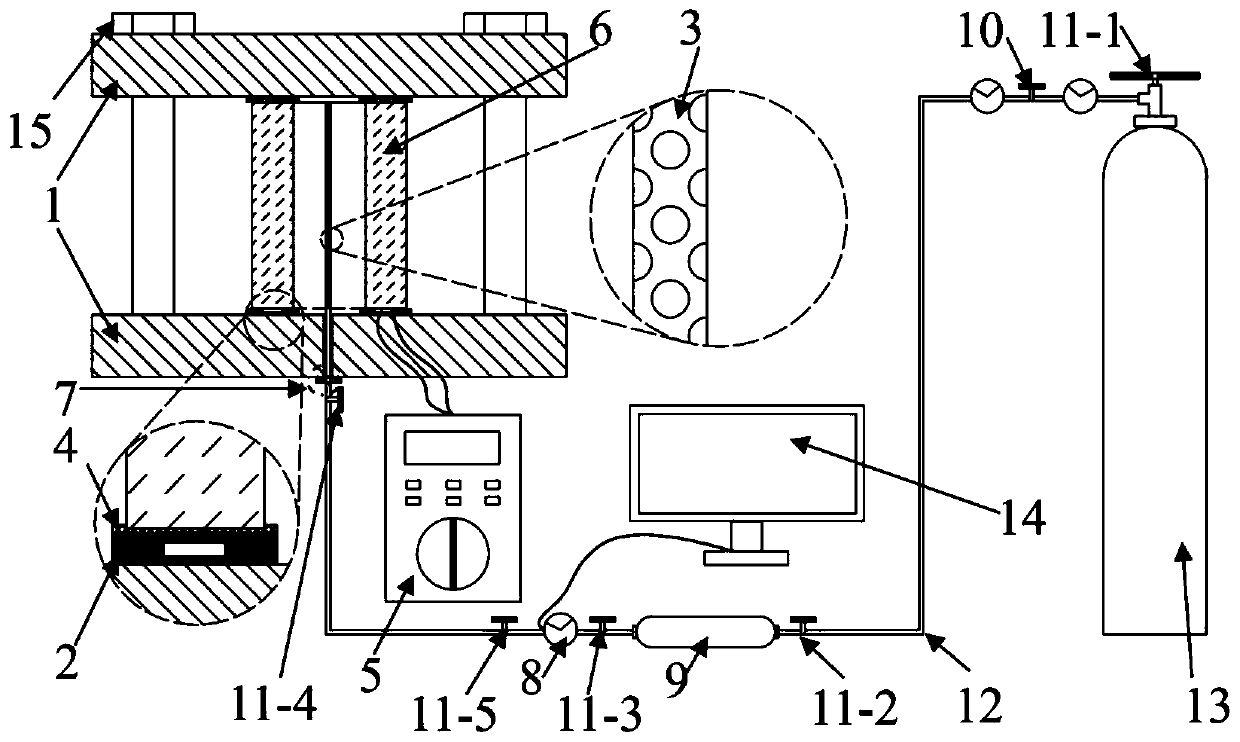

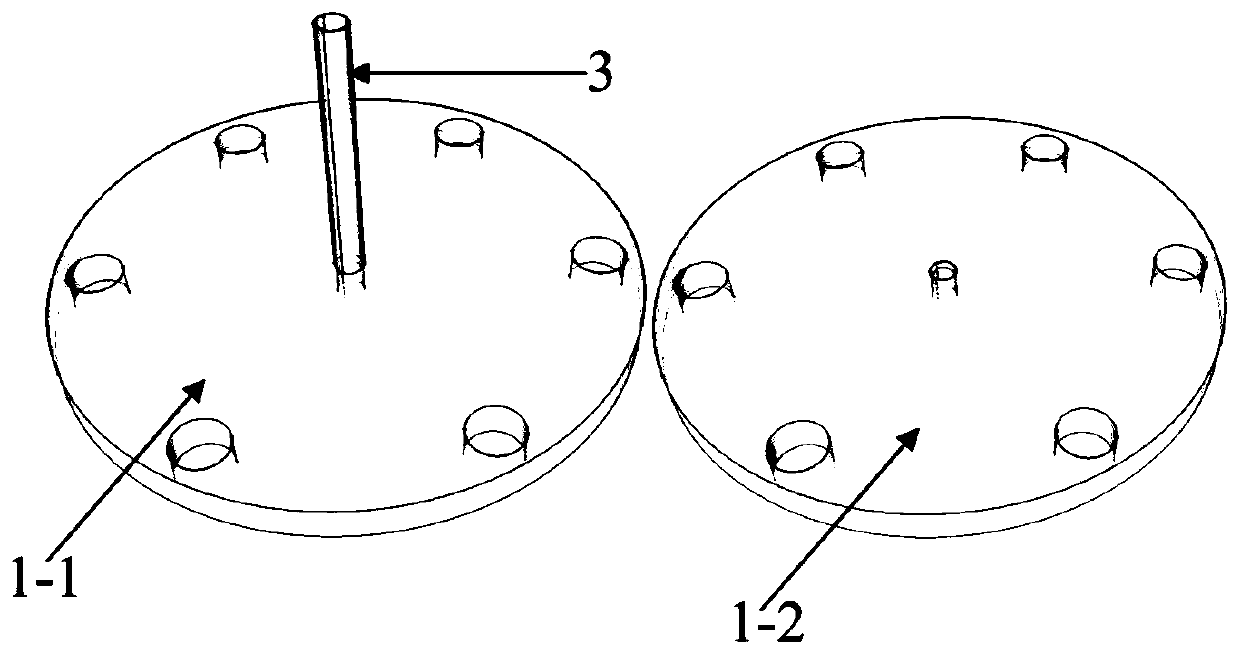

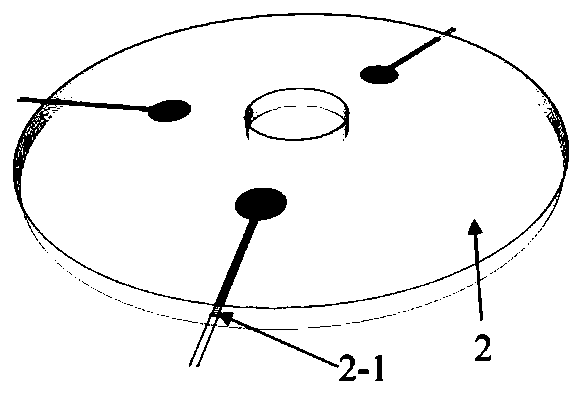

[0039] Such as figure 1 As shown, among them: 1-1 upper rigid sealing device, 1-2 lower rigid sealing device, 2 induction gasket, 3 gas diffusion tube, 4 adhesive, 5 multimeter, 6 sample, 7 gas nozzle, 8 barometer, 9 gas buffer bottle, 10 air pressure micro regulator, 11-1 first air valve, 11-2 second air valve, 11-3 third air valve, 11-4 fourth air valve, 11-5 fifth air valve , 12 gas conduits, 13 cylinders, 14 computers, 15 loading devices. The concrete gas radial permeability test device of the present invention includes a pressure device and a gas delivery device. The pressure device includes sample 6. Sample 6 in this embodiment is a concrete annular sample. Samples of different shapes can be set according to needs during testing; Bond the induction gasket 2, and then re-coat the self-leveling adhesive 4 on the surface of the induction gasket 2, and paste it in the middle of the whole body between the upper rigid sealing device 1-1 and the lower rigid sealing device 1-2...

Embodiment 2

[0056] The difference from Example 1 is that the mix ratio (g) of the prefabricated annular concrete sample 6 is: cement-433.0, sand-655, coarse aggregate (5-20mm)-1117, water-195, admixture-2.20. During the loading process, a multimeter was used to detect that each resistance in the induction washer was 2.6KΩ, and based on the characteristics of the sensor, the pressure on the induction washer was equivalent to the pressure of the sample, which was 0.5MPa. During the test, open the air valve on the high-pressure gas cylinder to make the air pressure reach about 4.01Bar, and use the air pressure micro-regulator to fine-tune the air pressure in the gas conduit to about 4.01Bar. The test results are as follows: Figure 5 shown.

Embodiment 3

[0058] The difference from Example 1 is that the mixing ratio (g) of the prefabricated annular concrete sample 6 is: cement-445.0, sand-652, coarse aggregate (5-20mm)-1142, water-156, admixture-4.45. During the loading process, a multimeter was used to detect that each resistance in the induction gasket was 1.62KΩ, and based on the sensor characteristics, the pressure on the induction gasket was converted to be 10.0MPa, which was equivalent to the pressure of the sample. During the test, open the air valve on the high-pressure gas cylinder to make the air pressure reach about 8.01Bar, and use the air pressure micro-regulator to fine-tune the air pressure in the gas conduit to about 8.01Bar. The test results are as follows: Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com