Preparation method of PEDOT:PSS high-conductivity porous flexible film

A flexible film and high conductivity technology, which is applied in the field of preparation of PEDOT:PSS high conductivity porous flexible film, can solve the problems of low capacitance performance, limited capacitance and active material loading, and achieve high charge and discharge stability and high rate Performance, Effect of High Conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

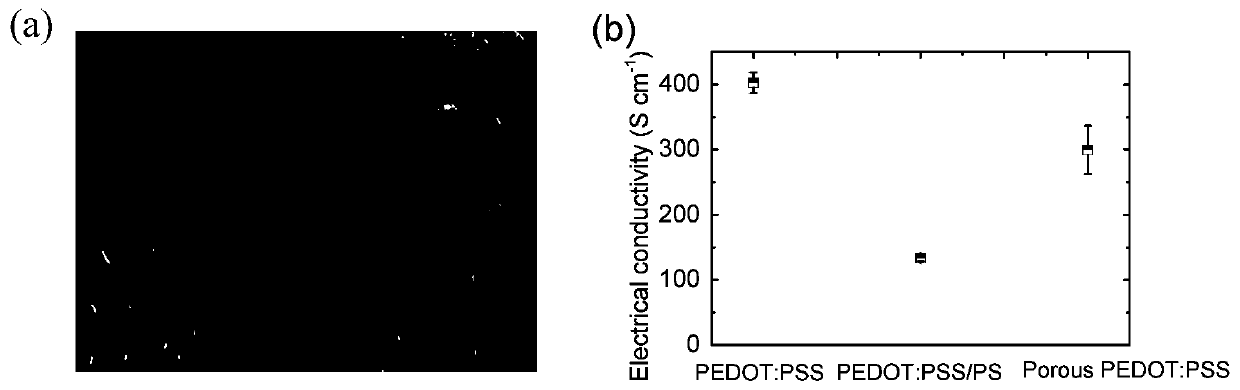

[0030] A preparation method of PEDOT:PSS highly conductive porous flexible film, comprising the following steps:

[0031] (1) Disperse 1000 μL PEDOT:PSS dispersion in 15 mL of ethanol, oscillate rapidly for 3 minutes, and ultrasonically disperse to obtain a mixture;

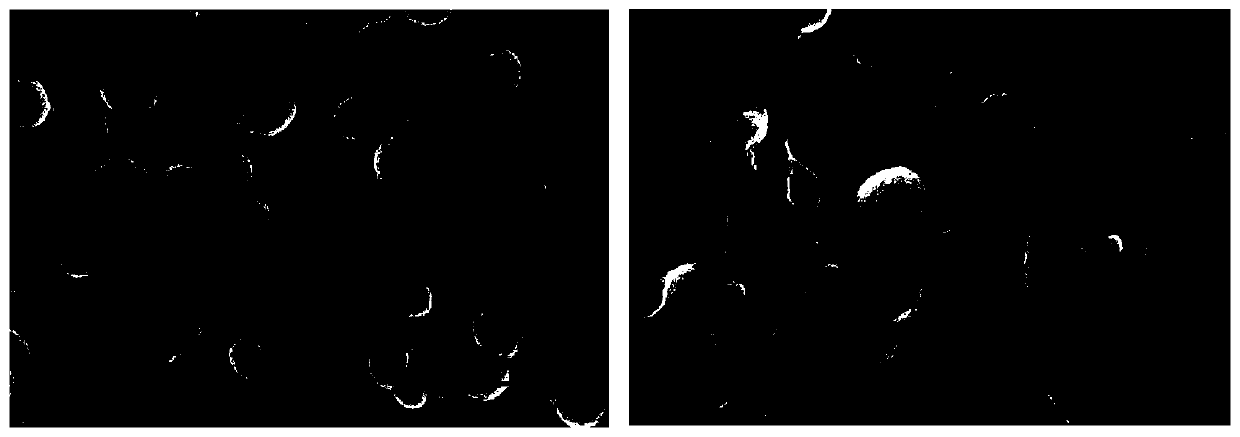

[0032] (2) Take 108 μL of PS nanosphere (100-300nm) dispersion solution and add it to the above mixture, and use an ultrasonic cell pulverizer with 30% power to sonicate for 30 minutes;

[0033] (3) Carry out vacuum suction filtration with the PVDF (0.45 μm) filter membrane of the above-mentioned ultrasonic solution;

[0034] (4) After suction filtration, immerse in deionized water to separate the filter membrane from the film and complete the stripping;

[0035] (5) rinse the film with ethanol, then dry naturally, and the film obtained is called PEDOT:PSS / PS film;

[0036] (6) Utilize tetrahydrofuran (THF) soaking 10min after drying, the film obtained is named porous PEDOT:PSS film;

[0037] (7) The porous PE...

Embodiment 2

[0041] A preparation method of PEDOT:PSS highly conductive porous flexible film, comprising the following steps:

[0042] (1) Disperse 1000 μL PEDOT:PSS dispersion in 15 mL of ethanol, oscillate rapidly for 3 minutes, and ultrasonically disperse to obtain a mixture;

[0043] (2) Take 108 μL of PS nanosphere (100-300nm) dispersion solution and add it to the above mixture, and use an ultrasonic cell pulverizer with 30% power to sonicate for 30 minutes;

[0044] (3) Carry out vacuum suction filtration with the PVDF (0.45 μm) filter membrane of the above-mentioned ultrasonic solution;

[0045] (4) After suction filtration, immerse in deionized water to separate the filter membrane from the film and complete the stripping;

[0046] (5) rinse the film with ethanol, then dry naturally, and the film obtained is called PEDOT:PSS / PS film;

[0047] (6) Utilize toluene to soak 10min after drying, the film obtained is named porous PEDOT:PSS film;

[0048] (7) The porous PEDOT:PSS film w...

Embodiment 3

[0052] A preparation method of PEDOT:PSS highly conductive porous flexible film, comprising the following steps:

[0053] (1) Disperse 1000 μL PEDOT:PSS dispersion in 15 mL of ethanol, oscillate rapidly for 3 minutes, and ultrasonically disperse to obtain a mixture;

[0054] (2) Take 108 μL of PS nanosphere (100-300nm) dispersion solution and add it to the above mixture, and use an ultrasonic cell pulverizer with 30% power to sonicate for 30 minutes;

[0055] (3) Carry out vacuum suction filtration with the PVDF (0.45 μm) filter membrane of the above-mentioned ultrasonic solution;

[0056] (4) After suction filtration, immerse in deionized water to separate the filter membrane from the film and complete the stripping;

[0057] (5) rinse the film with ethanol, then dry naturally, and the film obtained is called PEDOT:PSS / PS film;

[0058] (6) Utilize chloroform soaking 10min after drying, the film obtained is named as porous PEDOT:PSS film;

[0059] (7) The porous PEDOT:PSS ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com