Main outgoing line improvement mechanism of through-flow hydropower station generator

A hydroelectric power generator, through-flow technology, applied in the direction of using the reel/photosensitive drum layout, etc., can solve the problems of inability to use, inability to move and adjust, inability to connect, etc., to avoid direct connection , Increase the length and shorten the connection distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

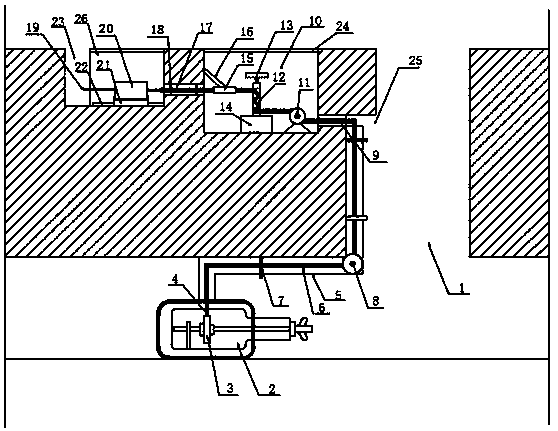

[0024] see Figure 1~2 , in an embodiment of the present invention, an improved mechanism for the main lead-out line of a tubular hydropower station generator includes a water turbine well 1, and a water turbine 2 is installed in the water turbine well 1, through which the energy of the water flow is converted into rotational mechanical energy , the water turbine 2 is protected by a protective cover, which can improve the stability of the water turbine 2, the water turbine 2 is provided with a stator 3, the stator 3 is connected to the cable 6 through the stator copper bar 4, and the stator 3, the stator copper bar 4 and the The cable 6 can transfer corresponding energy, so it can be used in daily life.

[0025] Further, the cable 6 is arranged in the connecting pipe 5, and the cable 6 is protected through the connecting pipe 5, which avoids the problem that the cable 6 is damaged by water, and has a very good protective effect. The connecting pipe 5 is arranged in the water t...

Embodiment 2

[0030] The difference between the embodiment of the present invention and embodiment 1 is that the top of the first equipment room 10 and the second equipment room 26 are provided with a cover plate 24, and the first equipment room 10 and the second equipment room 26 can be controlled by the cover plate 24. Cover to prevent people from getting lost. When it is necessary to increase the length of the connection, open the cover plate 24 and enter the first equipment room 10 and the second equipment room 26.

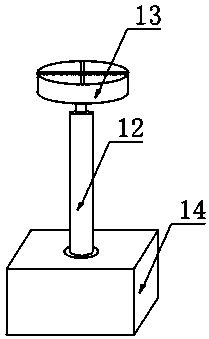

[0031] The working principle of the present invention is: when it is necessary to adjust the length of the connecting line, open the cover plate 24, enter the first equipment room 10 and the second equipment room 26, and by turning the rotating shaft 12, the cable 6 in the connecting pipe 5 will be straightened, thereby The length of the cable 6 in the first equipment room 10 and the second equipment room 26 is increased. By moving the slider 21, the length of the copper bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com