Mixing barrel for coal water slurry additive

A mixing tank and additive technology, which is applied to mixer accessories, mixers with rotating stirring devices, mixers, etc., can solve the problems of mixing dead angle, equipment cleanliness, and low mixing efficiency, so as to avoid mixing dead angle and reduce resources Damage, the effect of improving stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

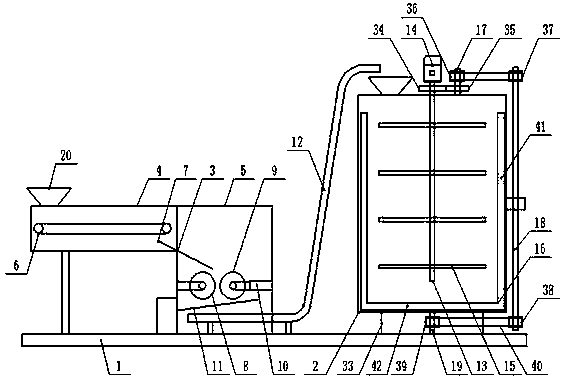

[0017] Embodiment 1: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6, now a description of a mixing tank for coal-water slurry additives provided by the present invention, including a base base 1, the upper end of the base base 1 is provided with a mixing tank 2, the upper end of the base base 1 is located in the mixing tank 2 A feeding mechanism 3 is provided on the side of the position, and the feeding mechanism 3 includes a feeding box body 4, a grinding box body 5, a conveying assembly 6, an inclined material guide plate 7, an active grinding roller 8, a driven grinding roller 9, a telescopic Cylinder 10, inclined vibrating mesh screen 11 and large inclination angle conveyor 12, the top of the mixing tank 2 is provided with a solid feed port and a liquid feed port, and the inner cavity of the mixing tank 2 is vertically provided with a stirring shaft 13, The outer top of the mixing bucket 2 is provided with a rotating motor 14 and the output sha...

Embodiment 2

[0018] Example 2: see figure 1 , a kind of mixing tank for the additive of coal-water slurry provided by the present invention is described now, and the upper end side of described grinding box body 5 is fixedly provided with described feed box body 4, and described feed box body 4 and described The fixed end faces of the grinding box 5 are all provided with guide ports, and the conveying assembly 6 is arranged in the feeding box 4 and the conveying assembly 6 is an existing equipment belt conveyor, and the feeding box The inner end wall of the body 4 is provided with a heating plate, and the upper end of the feeding box 4 is provided with a feeding port corresponding to the position of the feeding end of the conveying assembly 6. The upper end of the feeding box 4 and the upper end of the mixing barrel 2 are corresponding to The positions of the feeding inlet, the solid feeding inlet, and the liquid feeding inlet are respectively provided with a feeding funnel 20, and an air ...

Embodiment 3

[0019] Embodiment 3: see figure 1 , figure 2 , image 3 Now, a description is given to a mixing tank for coal-water slurry additive provided by the present invention, the inclined material guide plate 7 is arranged through the material guide port, and it is located below the position of the discharge end of the conveying assembly 6, The active grinding roller 8 is arranged in the grinding box 5 and below the position of the bottom end in the inclined direction of the inclined material guide plate 7, and the positions in the grinding box 5 and corresponding to the driving grinding roller 8 are spaced parallel to each other. The driven grinding roller 9 is arranged horizontally, the telescopic cylinder 10 is respectively arranged between the two ends of the length direction of the driven grinding roller 9 and the inner end wall of the grinding box 5, and the active grinding roller 8 An inclined vibrating screen 11 is arranged below the position, and the outer end wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com