Efficient grade enhancing machine

A hoist and high-grade technology, which is applied in the field of mining machinery, can solve problems such as environmental pollution, low production efficiency, and difficult adjustments, and achieve the effects of simplifying the process flow, reducing the floor area of the workshop, and uniform magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

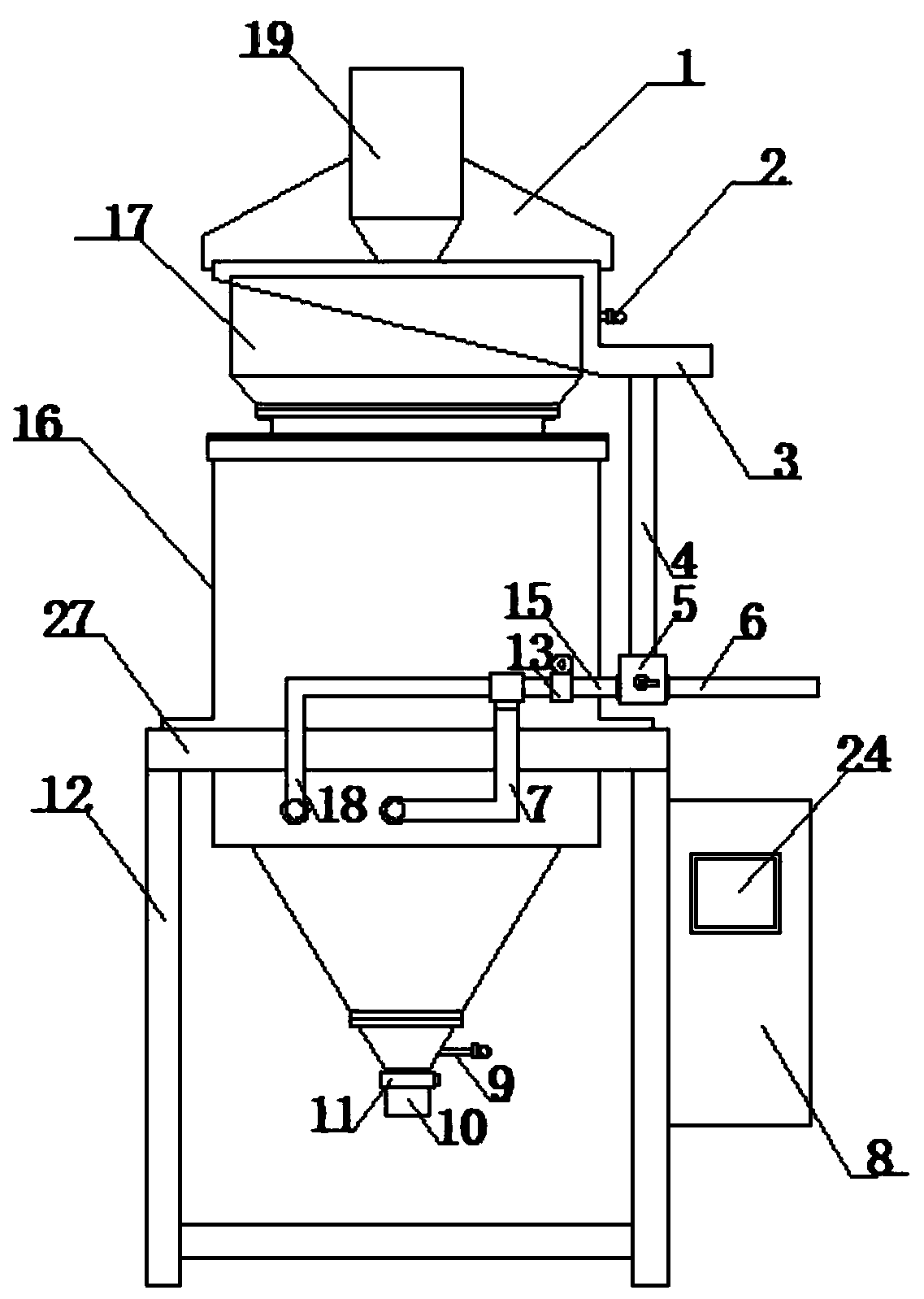

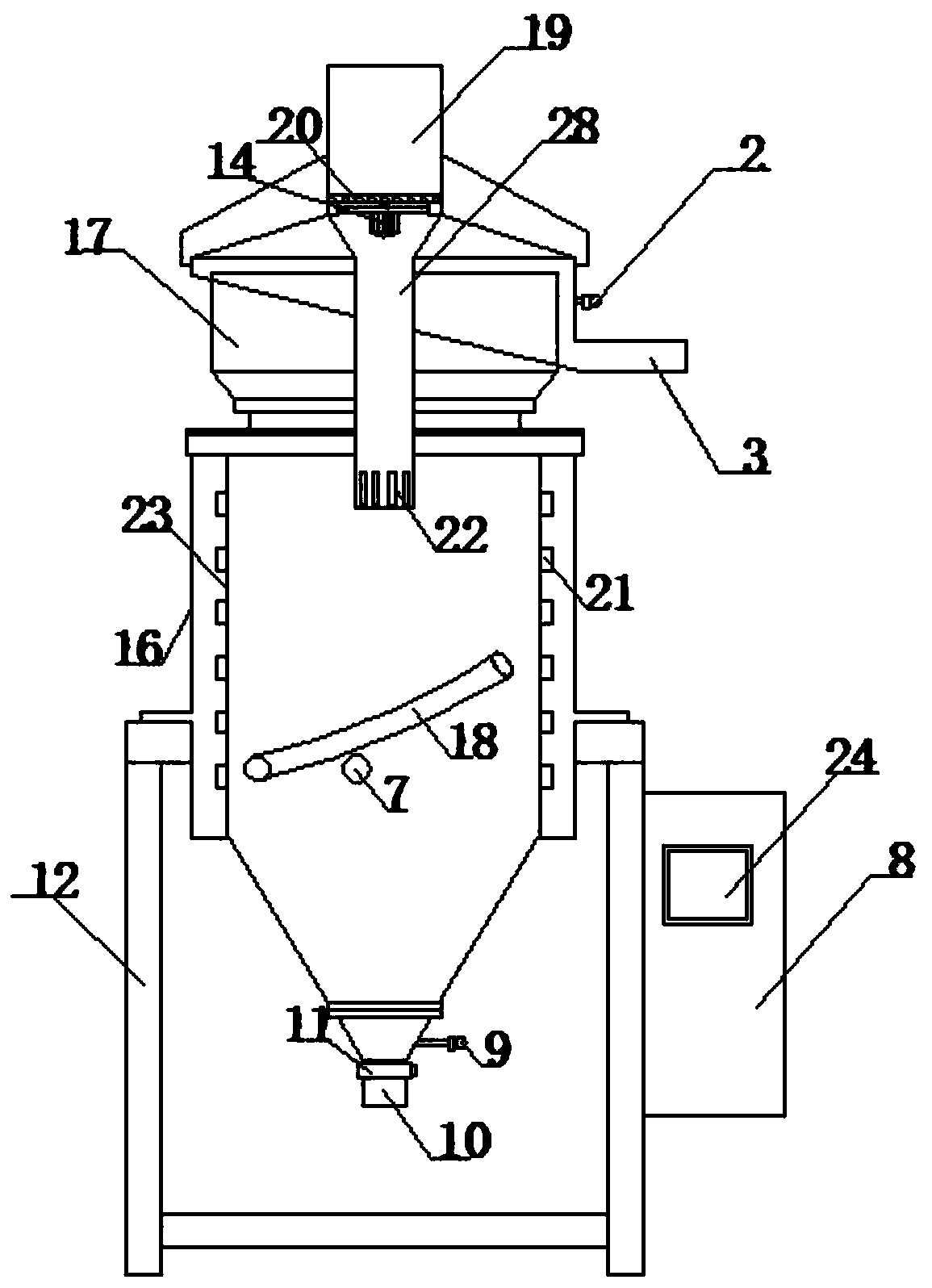

Embodiment 1

[0023] Such as Figure 1-3 As shown, a high-efficiency grade hoist includes a protective outer cylinder 16, a sorting inner barrel 23, an overflow box 17, a feed funnel 19, a control cabinet 8 and a support frame 12, and the protective outer cylinder 16 is sleeved with a sorting Inner barrel 23, the two sides of the sorting inner barrel 23 are equipped with electromagnets 21 through screws, and the top of the protection outer cylinder 16 is installed with an overflow box 17 connected to the top of the sorting inner barrel 23 through a mounting plate, and the overflow box 17 is a The overflow pipe 3 is welded on the side, the bottom of the overflow pipe 3 is connected to the return pipe 4, the bottom end of the return pipe 4 is connected to the three-way valve 5, one side of the three-way valve 5 is connected to the water inlet pipe 6, and the three-way valve 5. The other side is connected to the water main pipe 15, and the top of the overflow tank 17 is installed with a feed f...

Embodiment 2

[0032] Such as Figure 1-3As shown, a high-efficiency grade hoist includes a protective outer cylinder 16, a sorting inner barrel 23, an overflow box 17, a feed funnel 19, a control cabinet 8 and a support frame 12, and the protective outer cylinder 16 is sleeved with a sorting Inner barrel 23, the two sides of the sorting inner barrel 23 are equipped with electromagnets 21 through screws, and the top of the protection outer cylinder 16 is installed with an overflow box 17 connected to the top of the sorting inner barrel 23 through a mounting plate, and the overflow box 17 is a The overflow pipe 3 is welded on the side, the bottom of the overflow pipe 3 is connected to the return pipe 4, the bottom end of the return pipe 4 is connected to the three-way valve 5, one side of the three-way valve 5 is connected to the water inlet pipe 6, and the three-way valve 5. The other side is connected to the water main pipe 15, and the top of the overflow tank 17 is installed with a feed fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com