Composite metal surface protection layer and preparation method thereof

A metal surface and protective layer technology, which is applied in the field of metal surface composite protective layer and its preparation, can solve the problems of high production cost and unsatisfactory protective effect, and achieve the effect of low cost, excellent protective effect and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Use 80-mesh, 100-mesh, and 200-mesh sandpaper to polish the flat steel substrate in order to ensure that the surface of the substrate is flat and free of small particle protrusions. The grinding time is 5 minutes, and then the polished steel substrate is cleaned with acetone ultrasonically After 20 minutes, remove debris particles and oil stains on the surface of the steel substrate, and then perform ultrasonic cleaning with absolute ethanol for 10 minutes. During ultrasonic cleaning, the acetone and ethanol can be immersed in the steel substrate, and then dry at 80°C for 10 minutes to make the polished steel substrate The surface is dry, clean and free of stains;

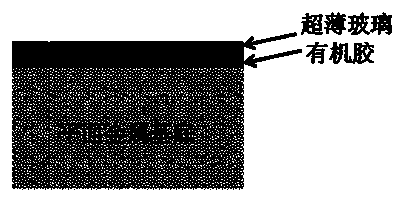

[0025] 2. On the surface of the steel substrate obtained in step 1), evenly brush a layer of 2 mm thick organic silica gel, and use a brush to repeatedly coat for 2 minutes so that the surface of the steel substrate (micro-sized surface defects such as pits and scratches) is covered with organic silica gel...

Embodiment 2

[0029] 1. Use 80-mesh, 100-mesh, and 200-mesh sandpaper to polish the flat steel substrate in sequence to ensure that the surface of the substrate is flat and free of small particle protrusions. The grinding time is 10 minutes, and then the polished steel substrate is ultrasonically cleaned with acetone for 10 minutes. , remove debris particles and oil stains on the surface of the steel substrate, and then perform ultrasonic cleaning with absolute ethanol for 15 minutes. During ultrasonic cleaning, acetone and ethanol can be immersed in the steel substrate, and then dry at 80°C for 20 minutes to dry the polished steel substrate surface. Clean and free of stains;

[0030] 2. On the surface of the steel substrate obtained in step 1), evenly brush a layer of 3mm-thick organic silica gel, and apply it repeatedly for 5 minutes with a brush to make the surface of the steel substrate (micro-sized surface defects such as pits and scratches) covered with organic silica gel cover;

[0...

Embodiment 3

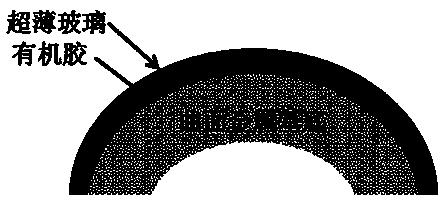

[0034] 1. Use 80-mesh, 100-mesh and 200-mesh sandpaper in sequence to polish the curved steel substrate with a curvature of 25% to ensure that the surface of the substrate is flat and free of small particle protrusions. The grinding time is 15 minutes, and then the polished curved steel substrate The substrate is ultrasonically cleaned with acetone for 15 minutes to remove debris particles and oil stains on the surface of the steel, and then ultrasonically cleaned with absolute ethanol for 15 minutes. During ultrasonic cleaning, the acetone and ethanol are immersed in the steel substrate, and then dried at 80°C for 30 minutes to make the grinding After the steel surface is dry, clean and free of stains;

[0035] 2. Evenly scrape and coat a layer of epoxy resin glue with a thickness of 1mm on the surface of the steel substrate obtained in step 1), and apply it repeatedly for 4 minutes with a brush to make the surface of the steel substrate (micro-sized surface defects such as pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com