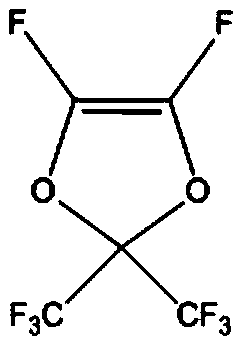

Preparation method of block copolymer containing perfluoro-2, 2-dimethyl-1, 3-dioxole

A dioxole and block copolymer technology, applied in chemical engineering and fields, can solve problems such as unreported, achieve the effect of promoting separation, ensure effective oxygen-promoting transport efficiency, and increase oxygen selective permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

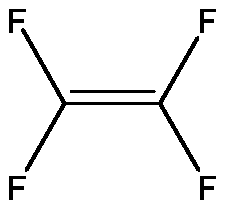

[0025]Add 100 grams of perfluoroheptane, 0.120 grams of diisopropyl peroxydicarbonate, and 0.062 grams of perfluoroiodobutane into the reaction kettle, seal the nitrogen and discharge oxygen until the oxygen concentration is less than 5ppm, and stir evenly; mix 20 grams of Perfluoro-2,2-dimethyl-1,3-dioxole and tetrafluoroethylene monomers (perfluoro-2,2-dimethyl-1,3-dioxole and tetrafluoroethylene The mass ratio of vinyl fluoride is 16.54:1) into the reaction kettle, stir evenly and heat up to 57°C, polymerize for 5 hours, cool to room temperature, remove unreacted tetrafluoroethylene monomer, and obtain iodine-terminated active poly(perfluoroethylene -2,2-Dimethyl-1,3-dioxole-co-tetrafluoroethylene) solution. To the resulting activated poly(perfluoro-2,2-dimethyl-1,3-dioxol-co-tetrafluoroethylene) solution was added 0.008 g of 1-vinyl cobalt complexable porphyrin imidazole, stir and heat up to 57°C, continue to polymerize for 4 hours, then cool to room temperature, the prod...

Embodiment 2

[0030] 100 grams of trifluorotrichloroethane / perfluoroheptane (perfluoroheptane: 30 wt%), 0.123 grams of diisopropyl peroxydicarbonate, and 0.236 grams of perfluoroiodohexane were added to the reaction kettle, and the Nitrogen exhausting oxygen until the oxygen concentration is less than 5ppm, stirring evenly; 20 grams of perfluoro 2,2-dimethyl-1,3-dioxole and tetrafluoroethylene monomer (perfluoro-2,2-di The mass ratio of methyl-1,3-dioxole to tetrafluoroethylene is 5.29:1) into the reaction kettle, stir evenly and heat up to 57°C, polymerize for 6 hours, cool to room temperature, and remove unreacted Tetrafluoroethylene monomer to obtain a solution of iodine-terminated living poly(perfluoro-2,2-dimethyl-1,3-dioxole-co-tetrafluoroethylene). To the resulting activated poly(perfluoro-2,2-dimethyl-1,3-dioxol-co-tetrafluoroethylene) solution was added 0.558 g of 4-vinyl cobalt complexable porphyrin Pyridine, stirred and raised to 57°C reaction setting temperature to continue pol...

Embodiment 3

[0035] 100 grams of trifluorotrichloroethane / perfluoro(2-n-butyltetrahydrofuran) (perfluoro(2-n-butyltetrahydrofuran): 30wt%), 0.123 grams of α-cumyl peroxyneodecanoate, Add 0.412 grams of 1,4-diiodoperfluorobutane into the reaction kettle, seal the nitrogen and discharge oxygen until the oxygen concentration is less than 5ppm, and stir evenly; add 20 grams of perfluoro 2,2-dimethyl-1,3-di Oxole and tetrafluoroethylene monomers (the mass ratio of perfluoro-2,2-dimethyl-1,3-dioxole to tetrafluoroethylene is 26.78:1) are added to the reactor , stir evenly and heat up to 50°C, polymerize for 6 hours, cool to room temperature, remove unreacted tetrafluoroethylene monomer, and obtain iodine-terminated active poly(perfluoro-2,2-dimethyl-1,3-diox Heterocyclopentene-co-tetrafluoroethylene) solution. To the resulting activated poly(perfluoro-2,2-dimethyl-1,3-dioxol-co-tetrafluoroethylene) solution was added 0.605 g of 4-butene that can complex cobalt porphyrin Pyridine, stir and heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com