Paint composition for woodware and wood product made of paint composition

A composition and coating technology, which is applied in the direction of surface coating liquid device, coating, pretreatment surface, etc., can solve the problems of unsatisfactory application, failure to meet application requirements, low hardness of dry coating film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

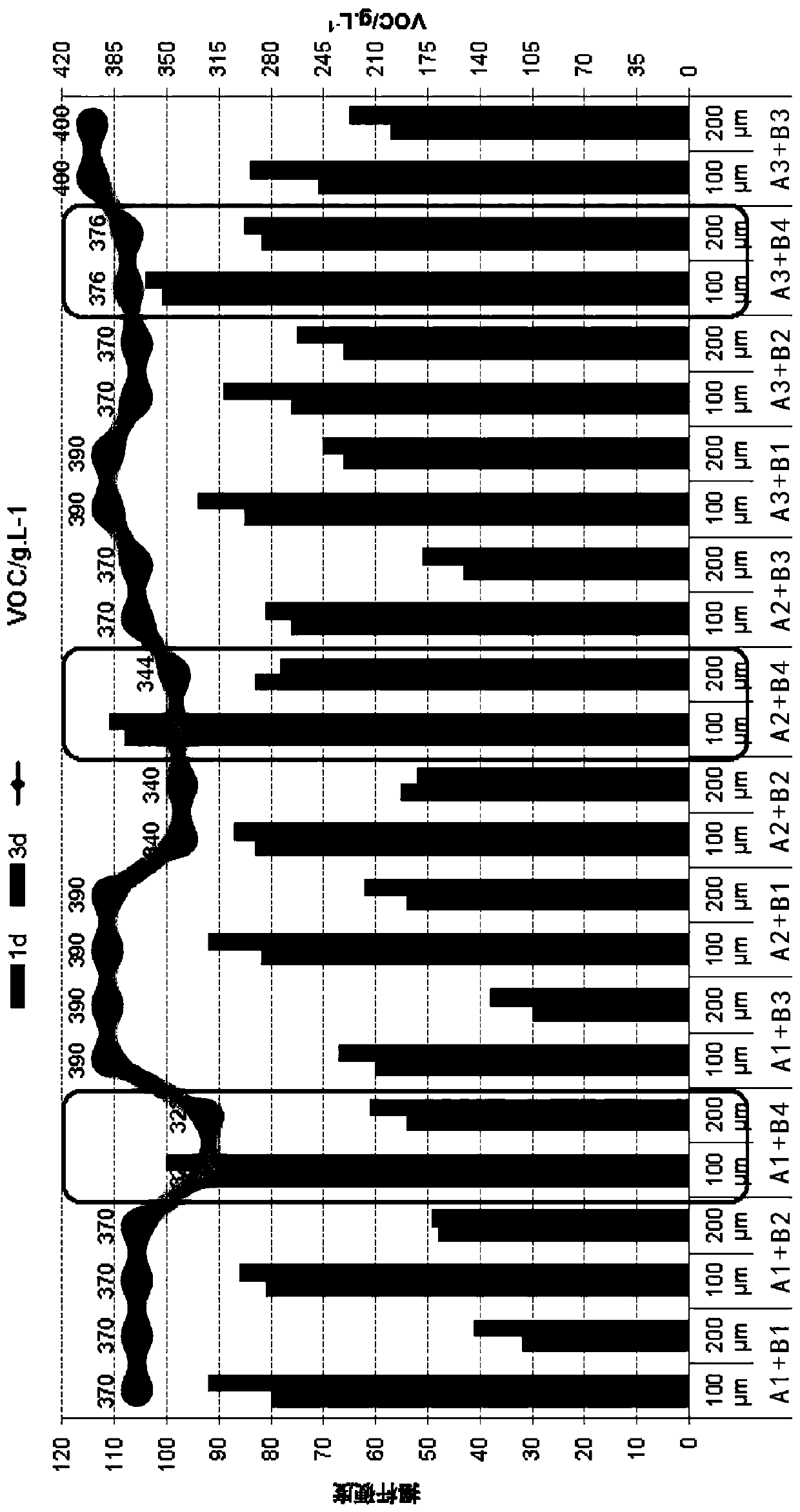

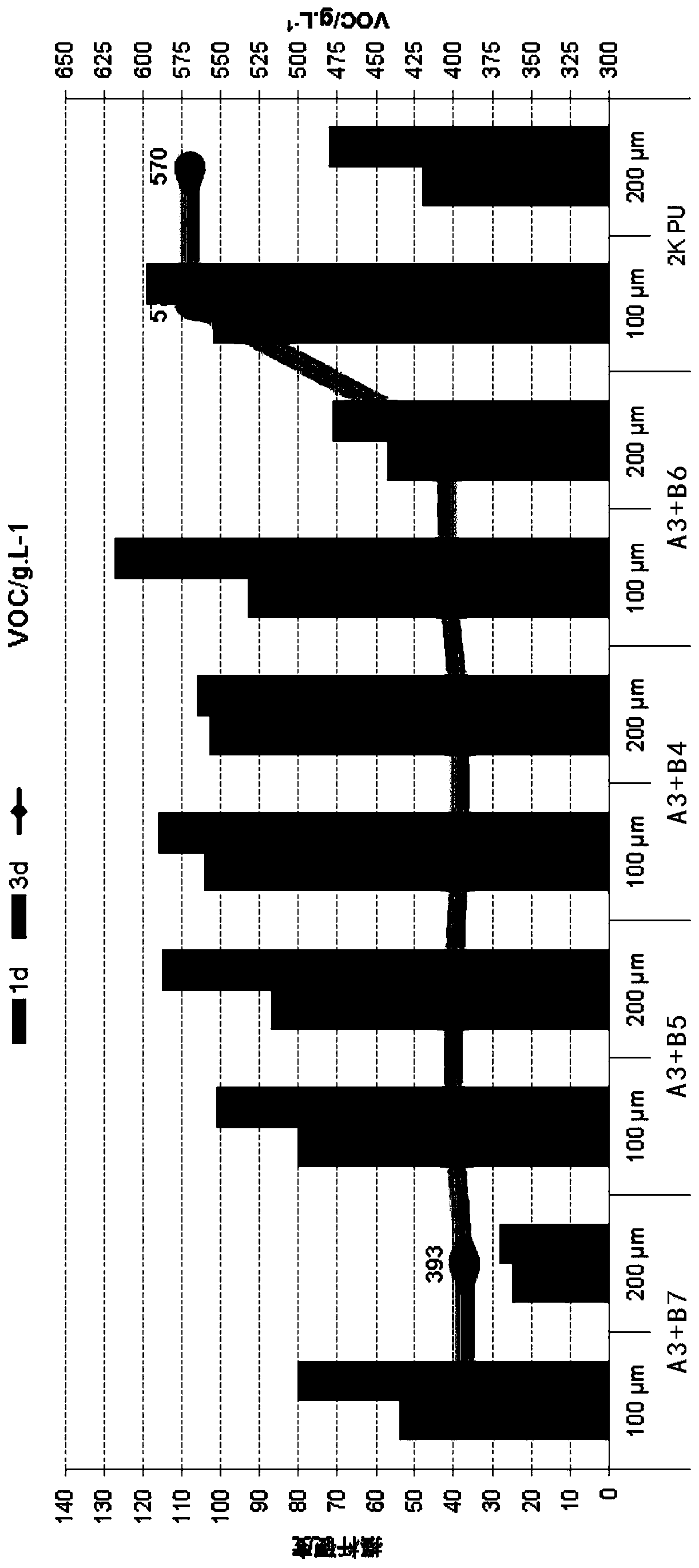

Image

Examples

Embodiment

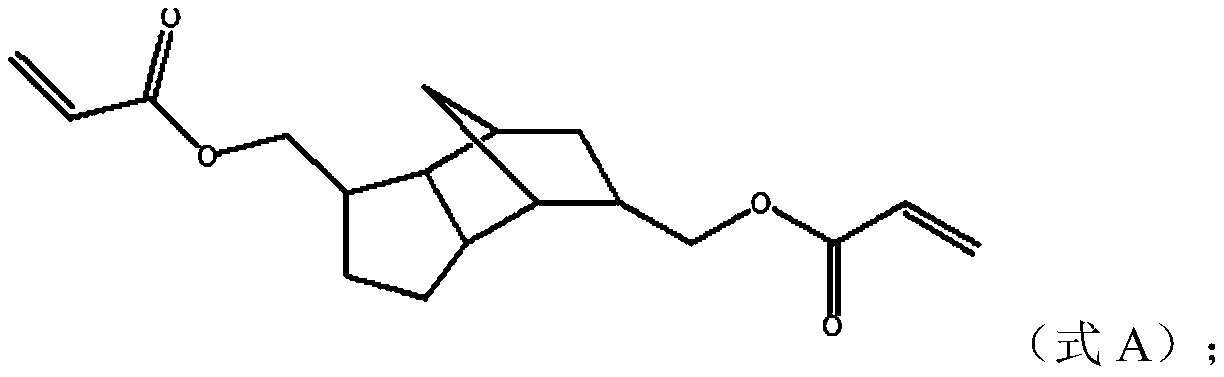

[0091] reactive donor

Synthetic example 1

[0092] Synthesis Example 1: Acetoacetate Epoxy Resin (A1)

[0093] At room temperature, 220.30 g of epoxy resin (NanYa, EEW: 471 g / mol) and 79.70 g of t-BAA were charged into a four-necked flask equipped with a thermometer, overhead stirrer, gas inlet and distillation apparatus. Supply N through the gas inlet 2 gas to provide N 2 Protect. The reaction mixture was then slowly heated to about 130°C and the distillate (tert-butanol) collected and maintained at this temperature until the distillation temperature did not exceed 78°C. Under these conditions (distillation temperature <= 78°C), the temperature of the mixture was raised to 160°C. When the temperature of the mixture reached 160°C, it was maintained until the distillation temperature was below 60°C. The mixture was then cooled to below 100°C and then mixed with n-butyl acetate (n-BA). The solids content is about 70%.

Synthetic example 2

[0094] Synthesis Example 2: Acetoacetate Epoxy Resin (A2)

[0095] Epoxy resin (NanYa, EEW: 622 g / mol), t-BAA and n-BA were 212.54, 87.46 and 101.02 g, respectively. The detailed synthesis procedure is the same as that of Synthesis Example 1 (A1). The solids content is about 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com