Industrial liquid fermentation method of alkaline protease

A technology of liquid fermentation and protease, applied in the field of bioengineering, can solve the problems of high production costs, meet the needs of the market, the process is easy to operate, and the effect of optimizing the fermentation mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

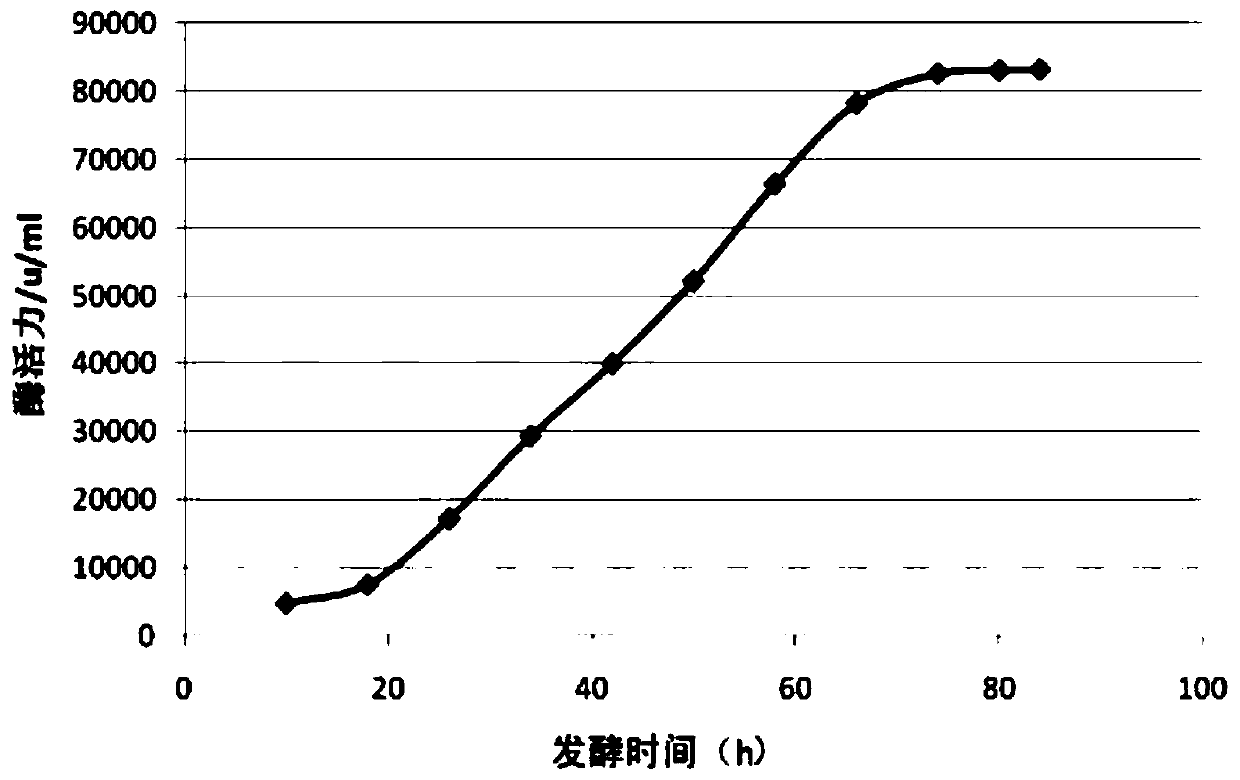

Image

Examples

Embodiment 1

[0021] The bacterial strain of alkaline protease of the present embodiment is the industrialized liquid fermentation method of bacterial classification, comprises the steps:

[0022] ① No. seed cultivation: Insert the bacterial strains capable of producing alkaline protease into a 1500 ml shake flask, choose Bacillus alkalophilus here, the medium loading capacity is 100 ml, the rotary shaker is 220 rpm, and the culture temperature is 36- 38°C, culture time 6-15h;

[0023] Cultivation of No. ② seeds: Inoculate No. ① seeds into 500 ml shake flasks according to 10% inoculum amount, the medium capacity is 100 ml, the rotary shaker is 220 rpm, the culture temperature is 36-38 °C, and the culture time is 6-6. 15h; culture conditions are the same as the first-class seeds;

[0024] Then carry out fermentation culture.

[0025] The medium used for fermentation is: fermentation medium g / L: yeast extract powder 20, cottonseed cake powder 30, maltodextrin 100, sodium citrate 3, calcium ...

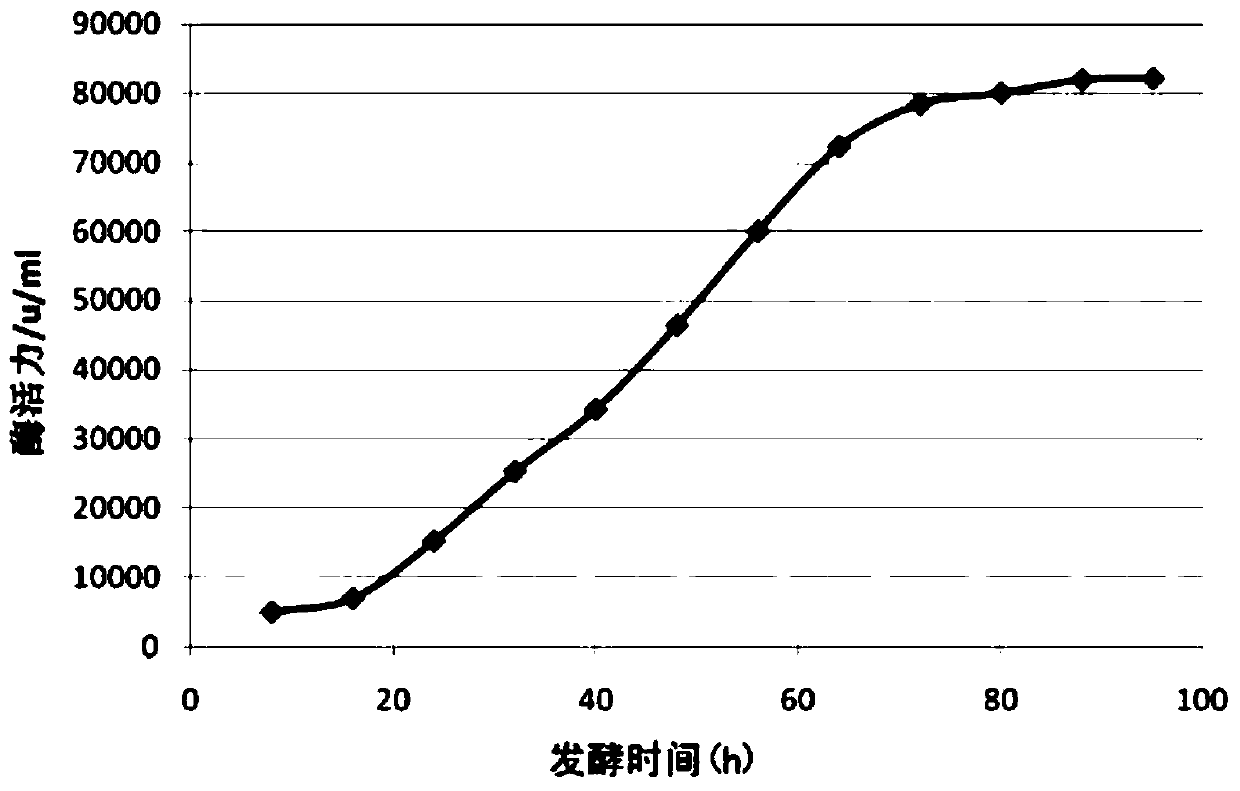

Embodiment 2

[0034] The bacterial strain of alkaline protease of the present embodiment is the industrialized liquid fermentation method of bacterial classification, comprises the steps:

[0035] ① Seed cultivation: Inoculate the strain of Bacillus alkalophilus into a 500ml shaker flask, with a medium capacity of 100ml, a rotary shaker at 240 rpm, a culture temperature of 36°C, and a culture time of 15 hours;

[0036] Cultivation of No. ② seed: Inoculate No. ① seed into a 500 ml shake flask according to 10% inoculum amount, the medium capacity is 100 ml, the rotary shaker is 240 rpm, the culture temperature is 36°C, and the culture time is 15 hours; culture conditions Same as Tier 1 seed;

[0037] Cultivation of No. ③ seed: Inoculate No. ② seed with 10% inoculum amount into a 500 ml shake flask, the medium capacity is 1000 ml, the rotary shaker is 100 rpm, the culture temperature is 34° C., and the culture time is 10 h.

[0038] Then carry out fermentation culture.

[0039] The medium us...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap