Precision quenching device for weld joint area

A quenching device, precise technology, applied in the direction of quenching devices, furnaces, heat treatment equipment, etc., can solve the problem of fixed quenching area, unable to adjust, etc., to achieve the effect of improving quenching effect, large room for adjustment, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

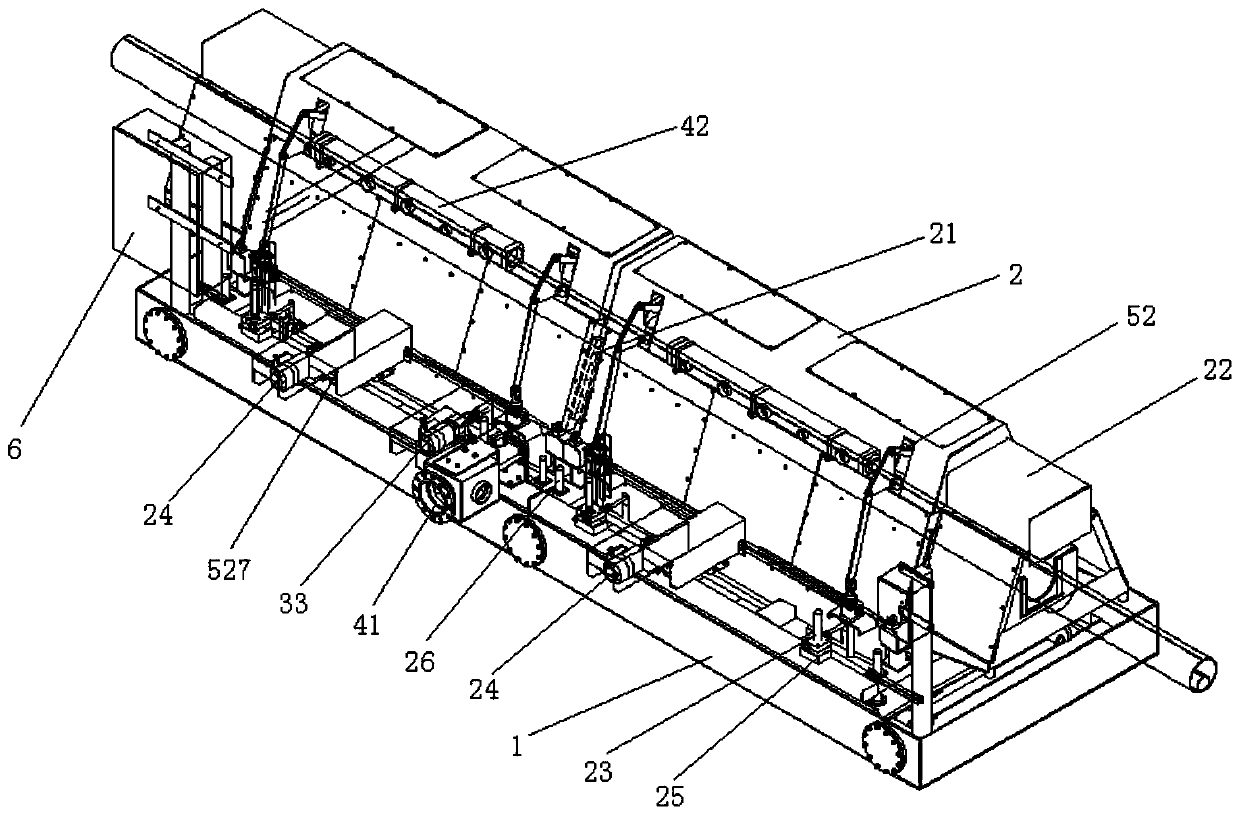

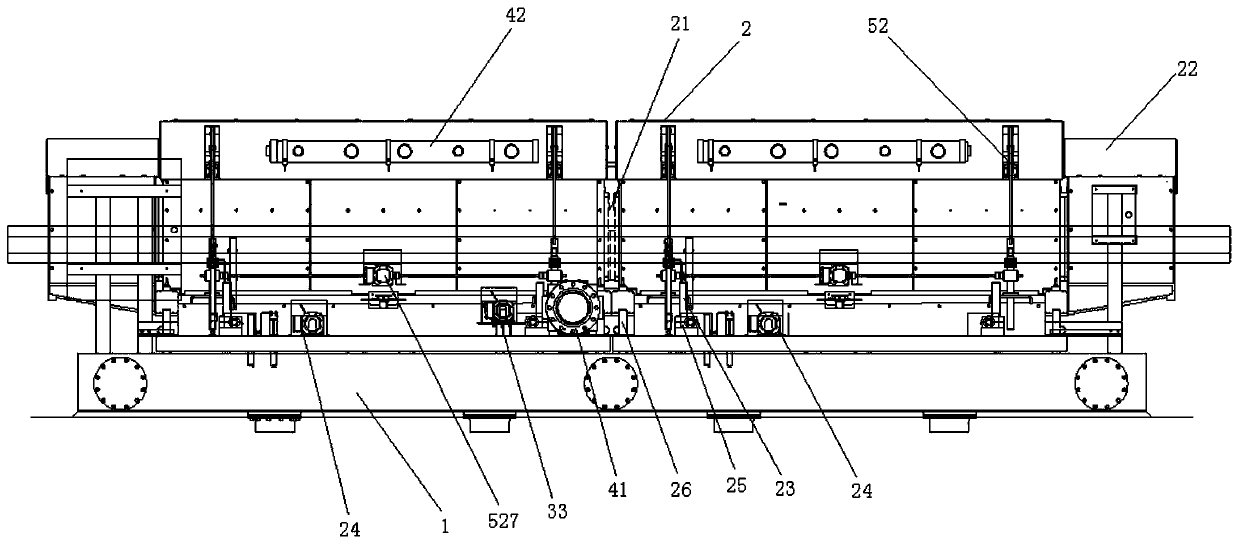

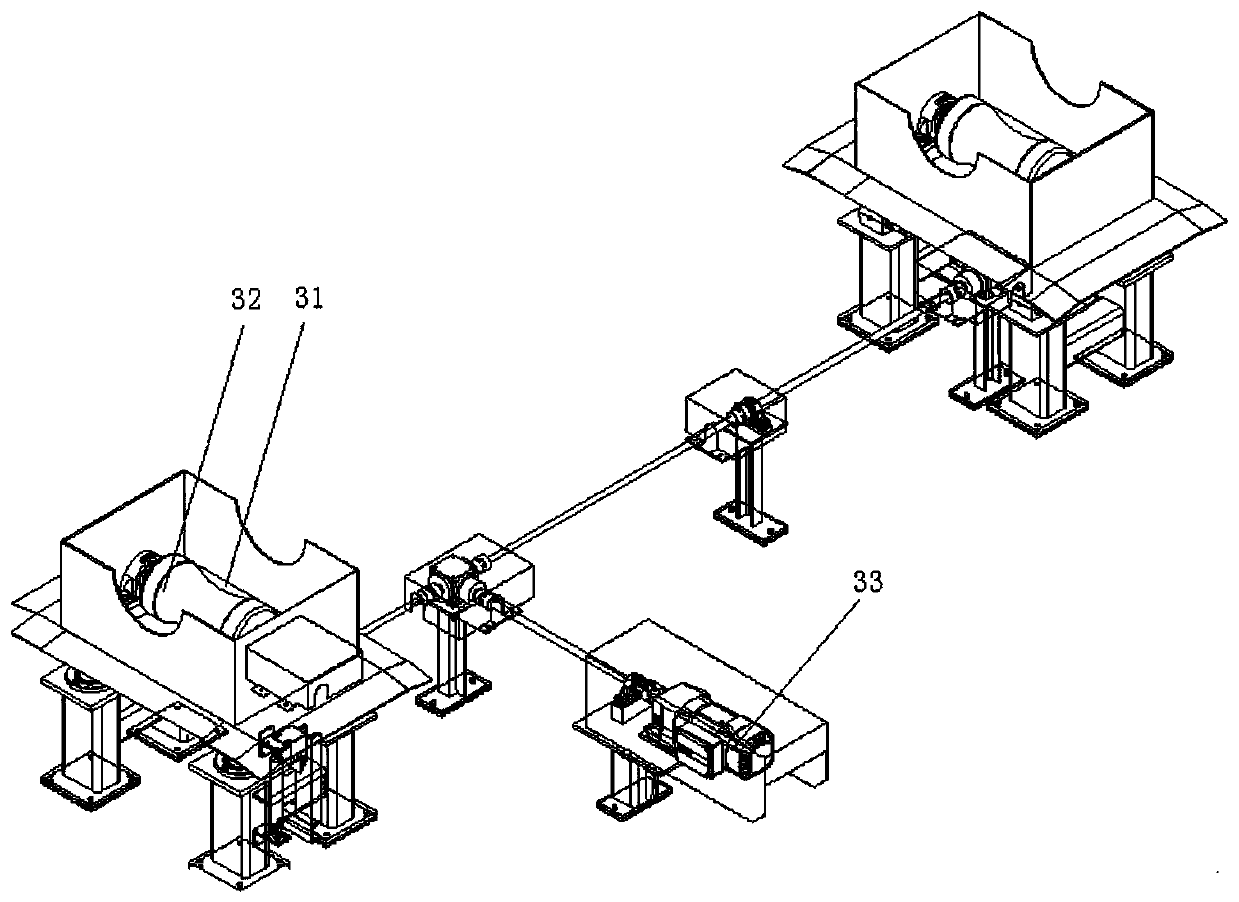

[0041] see Figure 1 to Figure 8 , in order to better understand the technical solution of the present invention, the following will be described in detail through specific embodiments in conjunction with the accompanying drawings:

[0042] see figure 1 and figure 2 , a precision quenching device for the weld area of the present invention, comprising a base 1, two quenching stations are arranged on the base 1, and a base frame 2 is respectively arranged on each quenching station. The end face of the base frame 2 is trapezoidal, and its upper surface and side slopes are respectively covered by sealing plates. At the same time, the two opposite end faces of the base frame 2 of the two quenching stations are connected to each other through the connecting plate 21, and the two outward end faces There is a sealing cover structure 22 at the place, so as to realize the complete sealing of the quenching station, so that when the quenching operation is performed, the splashing of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com