Environment-friendly friction material and brake pad and preparation method based on environment-friendly friction material

A friction material and environmental protection technology, applied in friction linings, chemical instruments and methods, mechanical equipment, etc., can solve the problems of low friction lining life, poor braking efficiency, damage to the dual disc, etc., and achieve long service life and comfortable braking. , does not damage the effect of the dual disk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

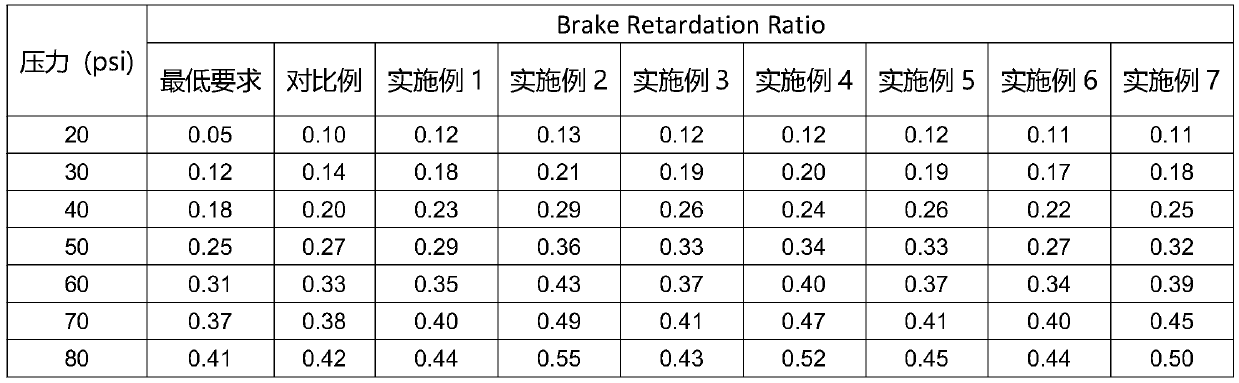

Examples

Embodiment 1

[0040] a) Components and mass percentage formula of environmentally friendly friction materials:

[0041] Silicon modified phenolic resin 5%, steel fiber 20%, mineral fiber 10%, aramid fiber 3%, graphite powder 15%, flake zinc powder 3%, barium sulfate 8%, titanate 8%, aluminum oxide 1 %, zirconia 8%, granular magnesium oxide 10%, calcium hydroxide 2%, rubber-based granules 7%.

[0042] b) Preparation of environmentally friendly friction materials:

[0043] (1) Weighing: Weigh all raw materials according to the composition and mass percentage of the environmental protection friction material;

[0044] (2) The first step of mixing: first take aramid fiber, mineral fiber, graphite powder, and barium sulfate according to the above ratio and add them to a 20L mixer, the stirring speed is 500 rpm, and the stirring time is 2-8 minutes;

[0045] (3) The second step of mixing: increase the stirring speed to 3000 rpm, and stir for 2-8 minutes;

[0046] (4) The third step of mixing m...

Embodiment 2

[0053] a) Components and mass percentage formula of environmentally friendly friction materials:

[0054] Silicon modified phenolic resin 8%, steel fiber 9%, mineral fiber 5%, aramid fiber 1%, graphite powder 30%, flake zinc powder 1%, barium sulfate 5%, titanate 5%, aluminum oxide 3 %, zirconia 15%, granular magnesium oxide 2%, calcium hydroxide 1%, rubber-based granular material 15%.

[0055] b) Preparation of environmentally friendly friction materials:

[0056] (1) Weighing: Weigh all raw materials according to the composition and mass percentage of the environmental protection friction material;

[0057] (2) The first step of mixing: first take aramid fiber, mineral fiber, graphite powder, and barium sulfate according to the above ratio and add them to a 20L mixer, the stirring speed is 500 rpm, and the stirring time is 8 minutes;

[0058] (3) The second step of mixing: increase the stirring speed to 3000 rpm, and stir for 2 minutes;

[0059] (4) The third step of mixi...

Embodiment 3

[0066] a) Components and mass percentage formula of environmentally friendly friction materials:

[0067] Silicon modified phenolic resin 3%, steel fiber 32%, mineral fiber 5%, aramid fiber 5%, graphite powder 10%, flake zinc powder 5%, barium sulfate 8.5%, titanate 10%, aluminum oxide 0.5% %, zirconia 8%, granular magnesium oxide 5%, calcium hydroxide 5%, rubber-based granules 3%.

[0068] b) Preparation of environmentally friendly friction materials:

[0069] (1) Weighing: Weigh all raw materials according to the composition and mass percentage of the environmental protection friction material;

[0070] (2) The first step of mixing: first take aramid fiber, mineral fiber, graphite powder, and barium sulfate according to the above ratio and add them to a 20L mixer, the stirring speed is 500 rpm, and the stirring time is 8 minutes;

[0071] (3) The second step of mixing: increase the stirring speed to 3000 rpm, and stir for 2 minutes;

[0072] (4) The third step of mixing: ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap