A device for naturally drying cutting slag and pressing bricks

A technology of natural drying and cutting slag, applied in drying chamber/container, drying solid materials, drying gas arrangement, etc., can solve the problems of incomplete drying, affecting the quality of finished bricks in drying efficiency, and ensure drying uniformity and stability. Contact area, the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

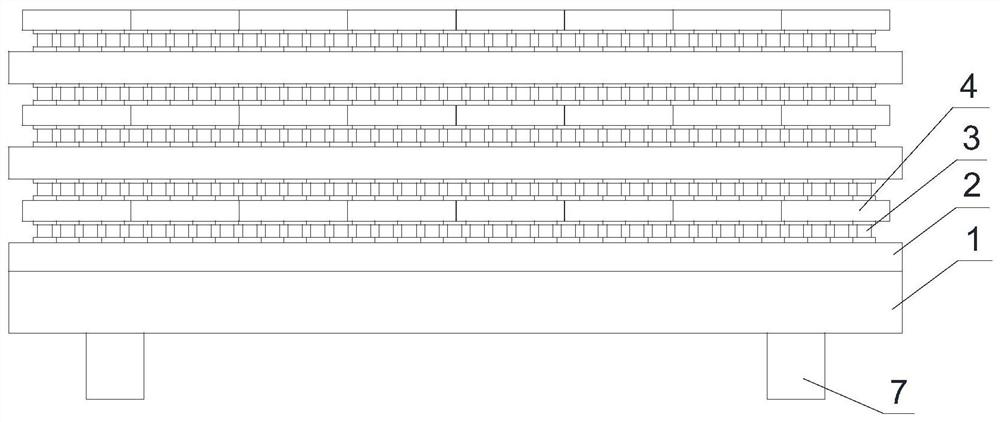

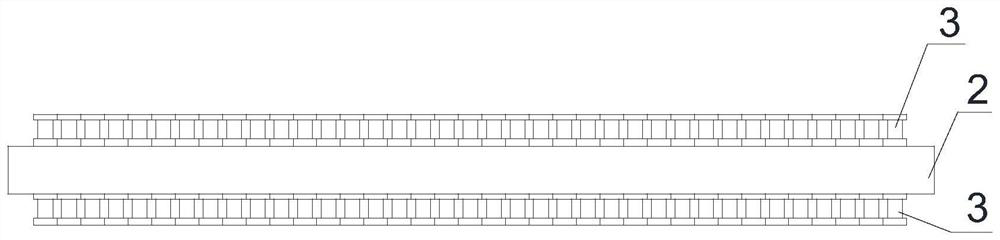

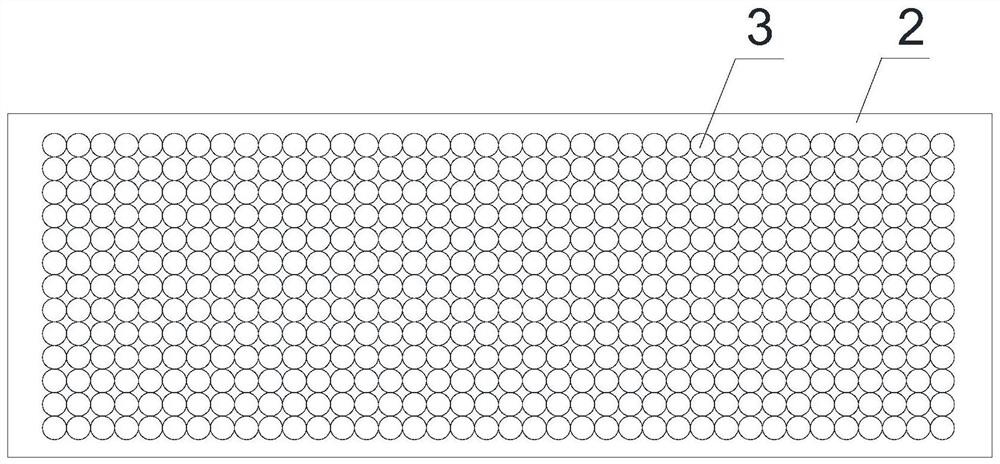

[0035] This embodiment provides a device for naturally drying cutting slag and pressing bricks, which includes a base 1 and a plurality of support plates 2, and a plurality of prefabricated cylinders 3 are distributed on the upper and lower surfaces of the support plate 2, and each prefabricated cylinder One axial end of the member 3 is in contact with the upper or lower plate surface of the support plate 2, and the other axial end is used to contact the pressed brick 4, and a plurality of ventilation holes 5 are opened on the side wall of the prefabricated cylinder member 3; the support plate 2 and pressed bricks 4 are stacked alternately on the upper surface of the base 1, and the prefabricated cylinders 3 have a cylindrical structure, and adjacent prefabricated cylinders 3 may partially contact each other, or leave sufficient gaps between them.

Embodiment 2

[0037] Further improvement on the basis of Embodiment 1, the prefabricated cylindrical member 3 includes a cylindrical body 31, a first ring plate 32 is provided along the circumferential direction at the open outer edge of the axial top end of the cylindrical body 31, and the first ring plate 32 is used for contact with the pressure The brick 4 contacts, and the outer edge of the axial bottom end of the cylinder 31 is provided with a second ring plate 33 along the circumference, and the second ring plate 33 is used to contact the upper or lower plate surface of the support plate 2 . The first ring plate 32 is provided with a plurality of ventilation grooves 34 on the plate contacting with the pressed bricks 4, and the plurality of ventilation grooves 34 are uniformly distributed in a radial shape along the circumference of the first ring plate 32, and each ventilation groove 34 is used for communication. The internal and external environment of the cylinder 31; the chamfering ...

Embodiment 3

[0039] Further improvement on the basis of Example 2, the upper and lower surfaces of the support plate 2 are provided with a plurality of columnar protrusions 6, and the axial end of the prefabricated cylinder 3 is interference fit sleeved on the columnar protrusions. 6, that is, the cylindrical boss 6 is adapted to be embedded in the bottom port of the cylinder body 31; the second ring plate 33 is an integrally formed structure of the cylinder body 31 with the outer flange at the bottom end of the axial direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com