Tool set for putty scraping and coating small-size sample plate

A complete set of tools and putty coating technology, applied in the preparation of test samples, etc., can solve the problems affecting the efficiency of scraping putty small samples, the relative position instability between the mold frame and the base material, and affecting the effect of putty scraping, etc., to achieve convenient Cleaning and maintenance, simple structure and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

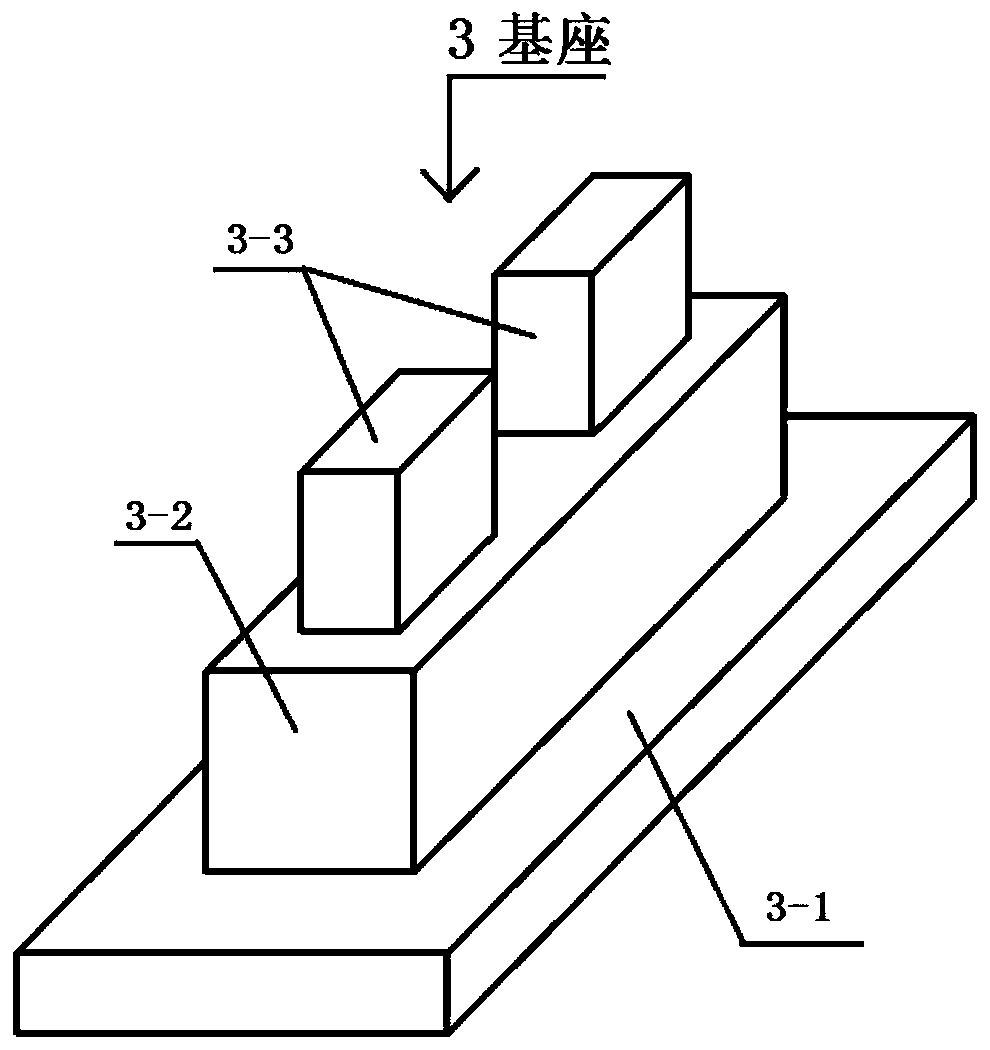

[0046] A complete set of tools for scraping putty small samples, the complete set of tools is composed of a frame 1, a support plate 2, a base 3 and a thickness limiting sheet 4, and the structures of each tool forming the complete set of tools are as follows:

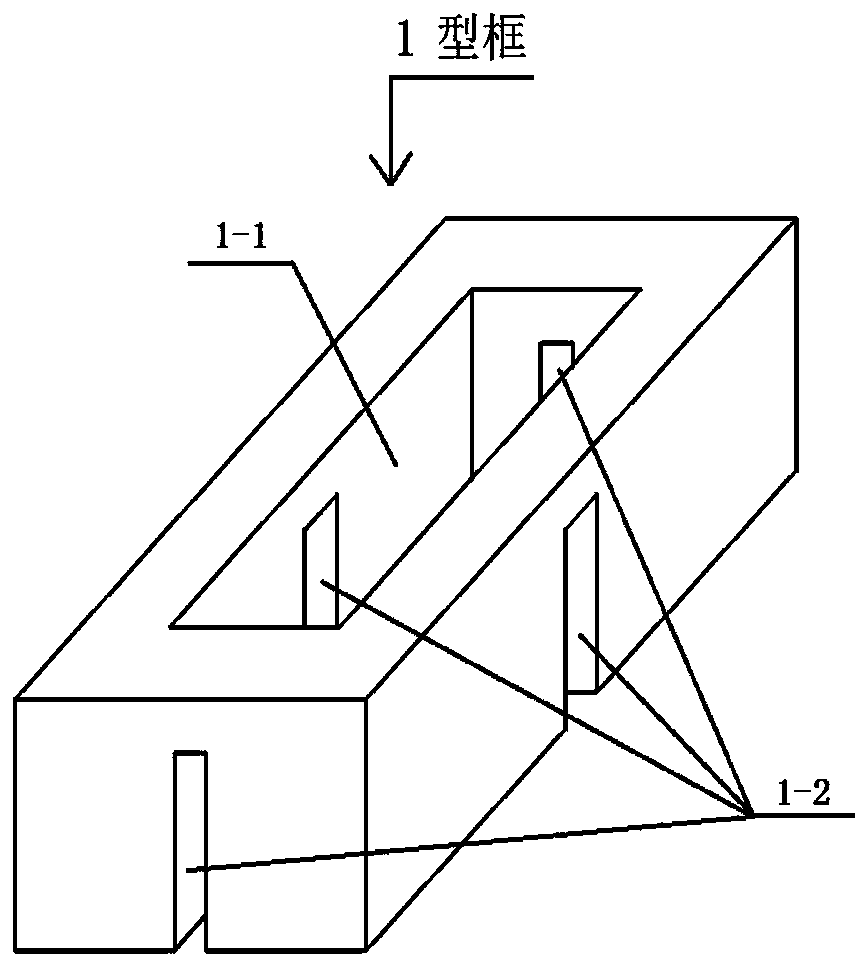

[0047] frame 1

[0048] Its shape structure is a rectangular body with a hollow structure, such as figure 1 As shown, the surface of the rectangular body is flat and smooth, and it has a hollow structure 1-1 in the shape of "Hui". , the hollow structure 1-1 of this embodiment is designed to have a length of 70mm x width of 150mm x thickness of 70mm. ×55mm Groove 1-2;

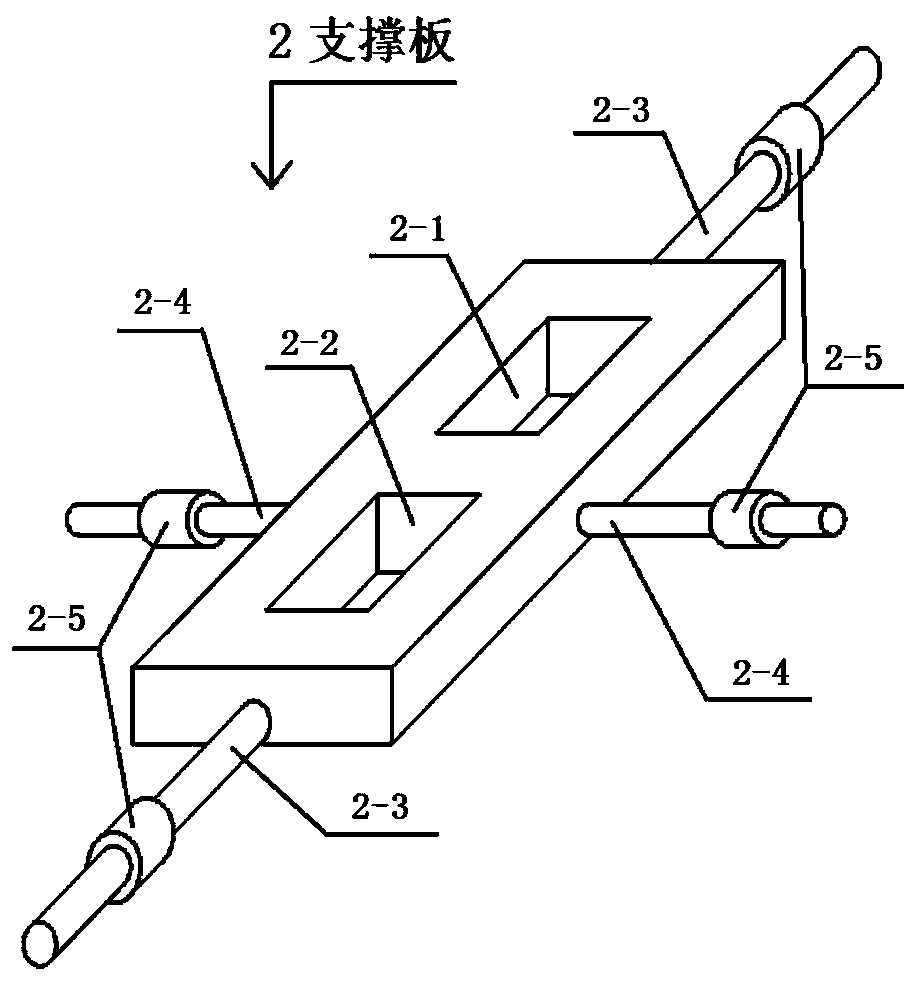

[0049] support plate 2

[0050] Such as figure 2 As shown, its external structure size is a cuboid with a length of 70mm~150mm×width 150mm~200mm×thick 20mm. Both are two hollow structures 2-1 and 2-2 with a length of 40 mm to 120 mm × a width of 30 mm to 80 mm × a thickness of 20 mm. The dimensions of the two hollow structures 2-1 and 2-2 in this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com