CO2 pressurization metering system and use method

A metering system, CO2 technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of agitator corrosion, pulse, and test simulation functions that cannot be fractured, and achieve stability The effect of injecting functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

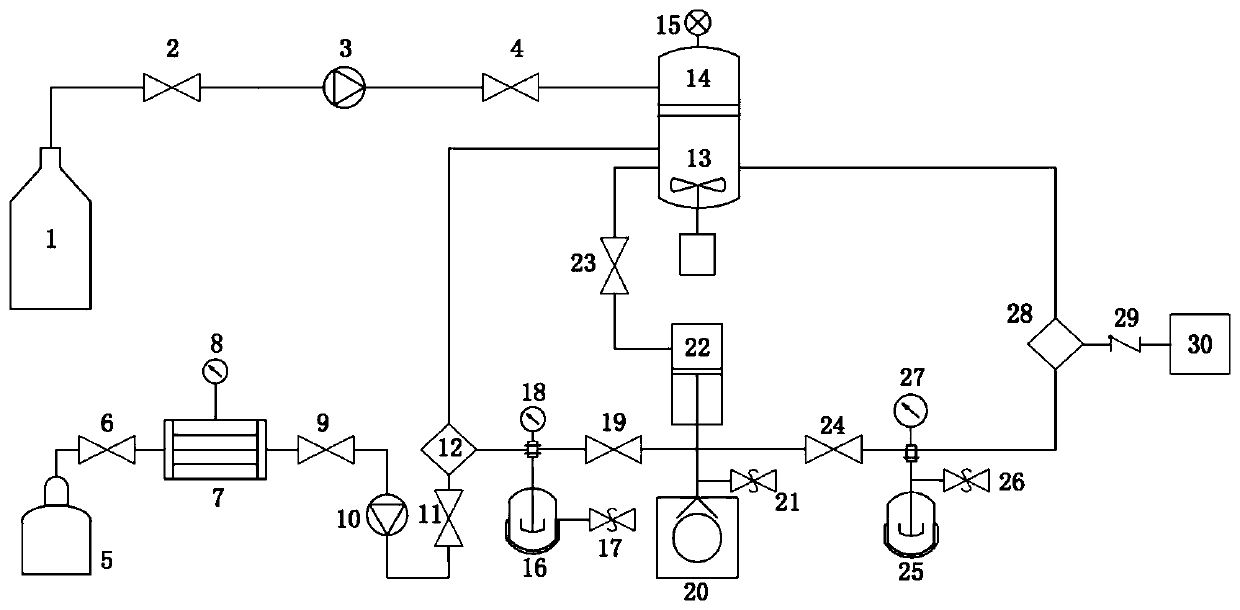

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0036] Compared with the conventional true triaxial fracturing simulation equipment that only has the function of hydraulic fracturing, this experimental system focuses on adding CO 2Mixed with chemical reagents, pressurized injection and accurate metering functions, with the help of this system for CO 2 Fracturing injection functions for better control. During the experiment, it is necessary to apply a certain confining pressure to the experimental rock sample with the help of conventional true triaxial fracturing simulation equipment (well known in the industry), which can facilitate better research on fracture initiation pressure and fracturing effect.

[0037] like figure 1 As shown, the present invention provides a CO 2 Boost metering control system, including liquid storage tank 1, first valve 2, mixed liquid metering pump 3, second valve 4, gas stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com