Continuous production line for mine stone

A production line and stone material technology, applied in fixed filter element filter, filtration separation, grain processing, etc., can solve problems such as lack of water filtration and recycling devices, water can not achieve the effect of spray washing, and reduce water utilization efficiency. Achieve the effects of increasing production income, safe and convenient use, and reducing entry difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

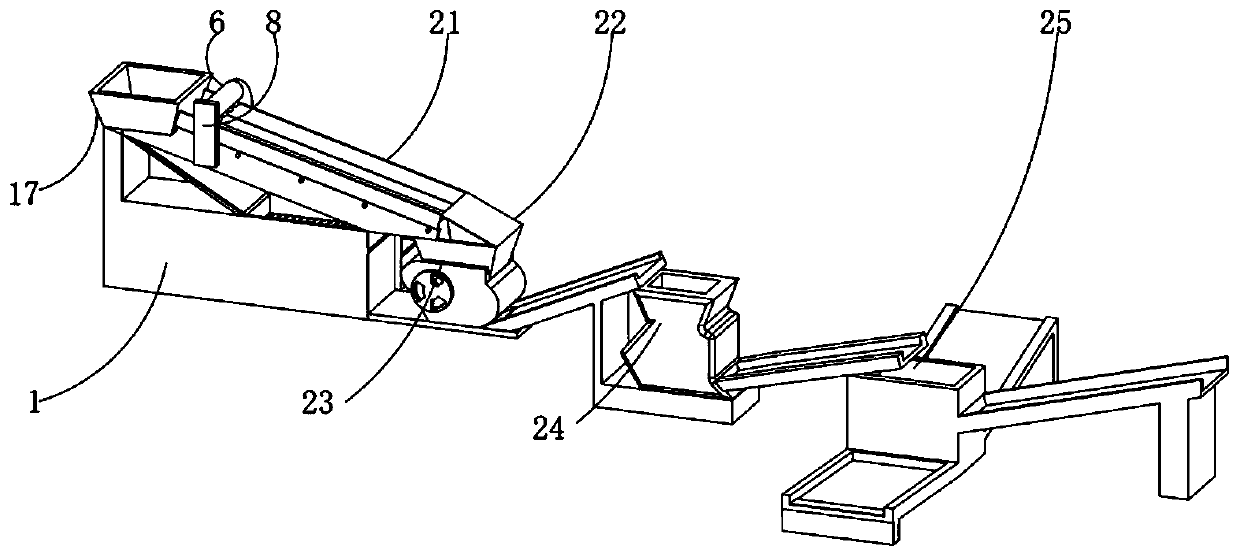

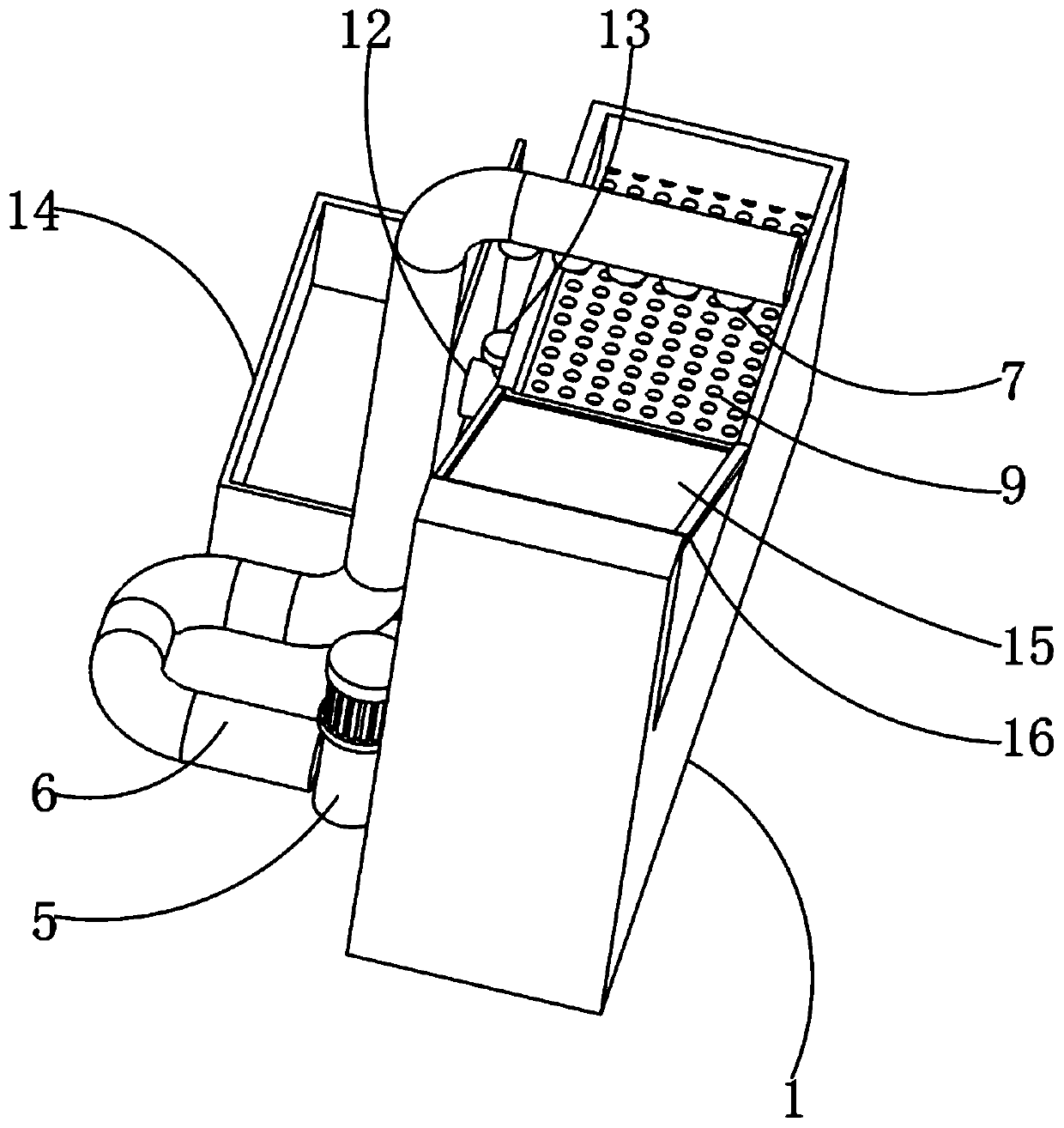

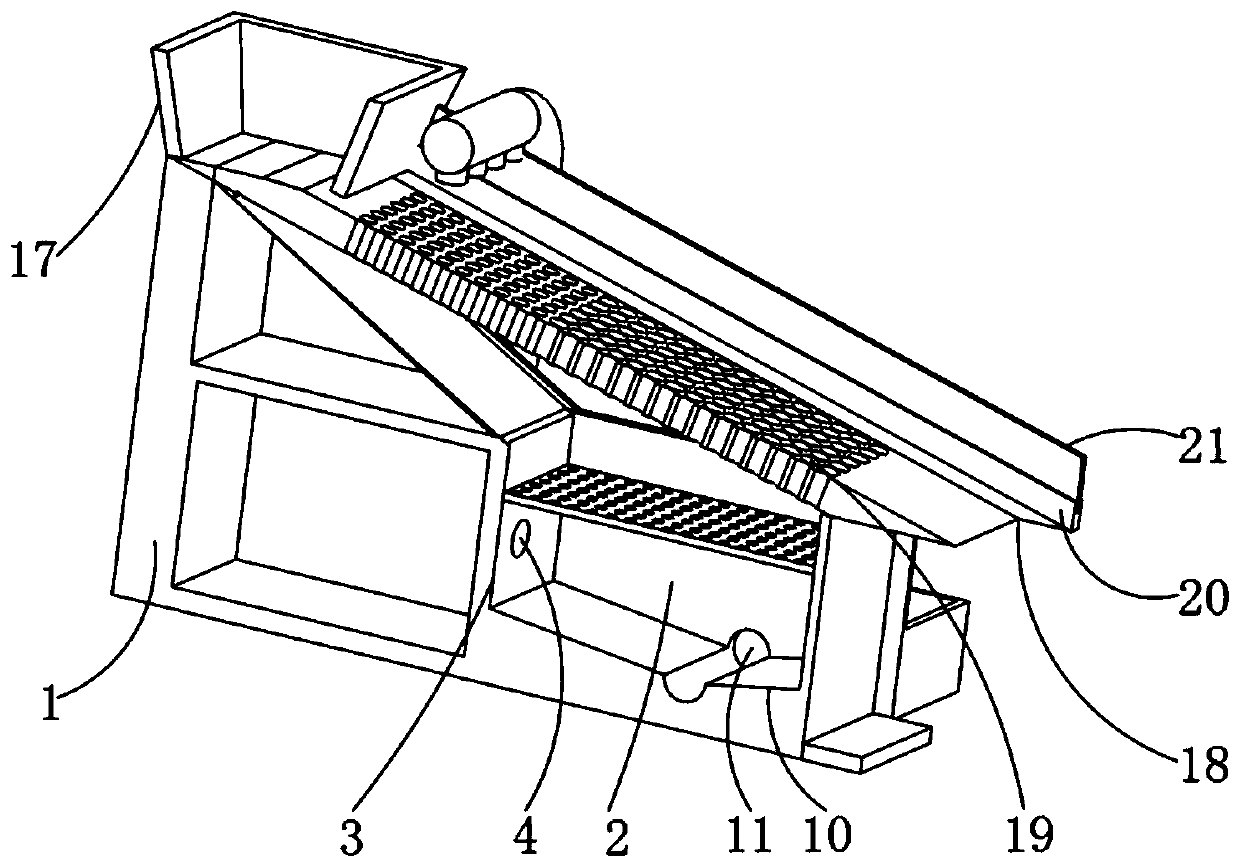

[0022] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a continuous mine stone production line, including a support base 1, an impact crusher 23 is connected to one end of the support base 1, and a jaw crusher 24 is connected to one end of the impact crusher 23, One end of the jaw crusher 24 is connected to a vibrating screen 25, and the impact crusher 23, the jaw crusher 24 and the vibrating screen 25 are all connected by a conveyor belt. 2 A partition plate 3 is installed in the middle of the inner wall, a through hole 4 is opened in the middle of one end of the partition plate 3, and a liquid suction pump 5 is installed on one side of the back side of the storage chamber 2. The model of the liquid suction pump 5 is JK-3P. One end of the liquid pump 5 is connected to a water pipe 6, and the top of the outer surface of the water pipe 6 is equidistantly embedded with nozzles 7, and the middle part of one end of the water pipe 6 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com