Iron-indium annular composite microcrystal turntable

A microcrystalline, ring-shaped technology, applied in the direction of tubular articles, metal layered products, applications, etc., to achieve the effect of uniform performance distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

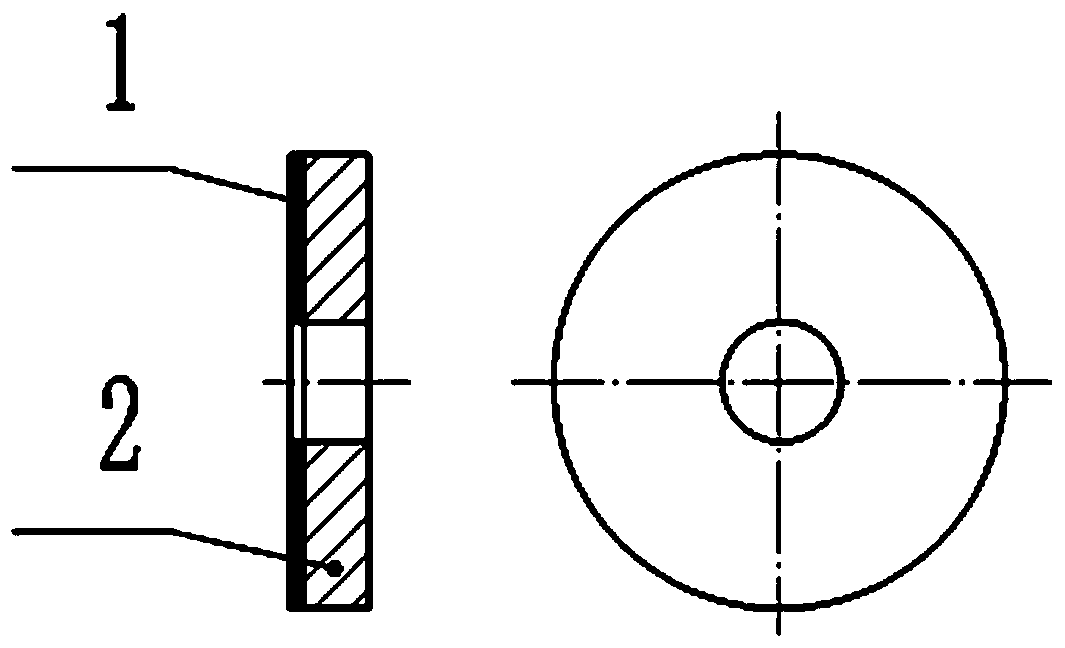

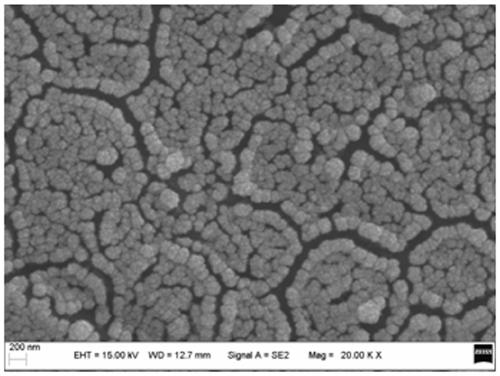

[0017] figure 1 It is a schematic structural diagram of the iron-indium annular composite microcrystal turntable in Example 1 of the present invention, figure 2 It is a scanning electron microscope image of the surface material layer of the iron-indium annular composite microcrystal turntable sample in Example 1 of the present invention. In the drawings, 1 is the surface material layer, and 2 is the matrix material.

[0018] The feature of the iron-indium annular composite microcrystal turntable of the present invention is that in a dry and clean air environment, the 40Cr steel material is kept at 170°C for 5 minutes, cooled rapidly, and the turntable parts are made by mechanical processing. After grinding, cleaning, degreasing and derusting the corresponding surface of the turntable parts, after fine grinding, ultrasonic cleaning and drying, a surface material layer is set on the turntable parts. The main component of the surface material layer is iron containing more than 4...

Embodiment 2

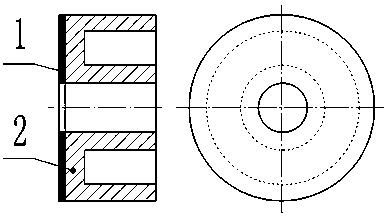

[0021] image 3 It is a schematic structural diagram of an iron-indium annular composite microcrystal turntable according to Example 2 of the present invention. In the drawings, 1 is a surface material layer, and 2 is a matrix material.

[0022] The main difference between the embodiment of the present invention and embodiment 1 is that the embodiment of the present invention processes an annular concave hole in the turntable part, and can place an opto-electromagnetic device in it, so as to precisely restrict the flowing liquid or gas and change the flowing liquid or gas. path and state and speed etc.

[0023]The feature of the iron-indium ring-shaped composite microcrystal turntable of the present invention is that in a dry and clean air environment, the 40Cr steel material is kept at 170°C for 5 minutes, cooled rapidly, and the turntable parts are made by mechanical processing. It has a circular inner concave hole. After grinding, cleaning, degreasing and rust removal on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com