Double-stage track high speed railway transporting system

A high-speed railway and transportation system technology, applied in the direction of railway car body parts, etc., can solve the problems of high construction and operation costs, low high-speed railway carrying capacity, and difficulty in increasing the speed per hour, so as to achieve low construction and operation costs, increase carrying capacity, High safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

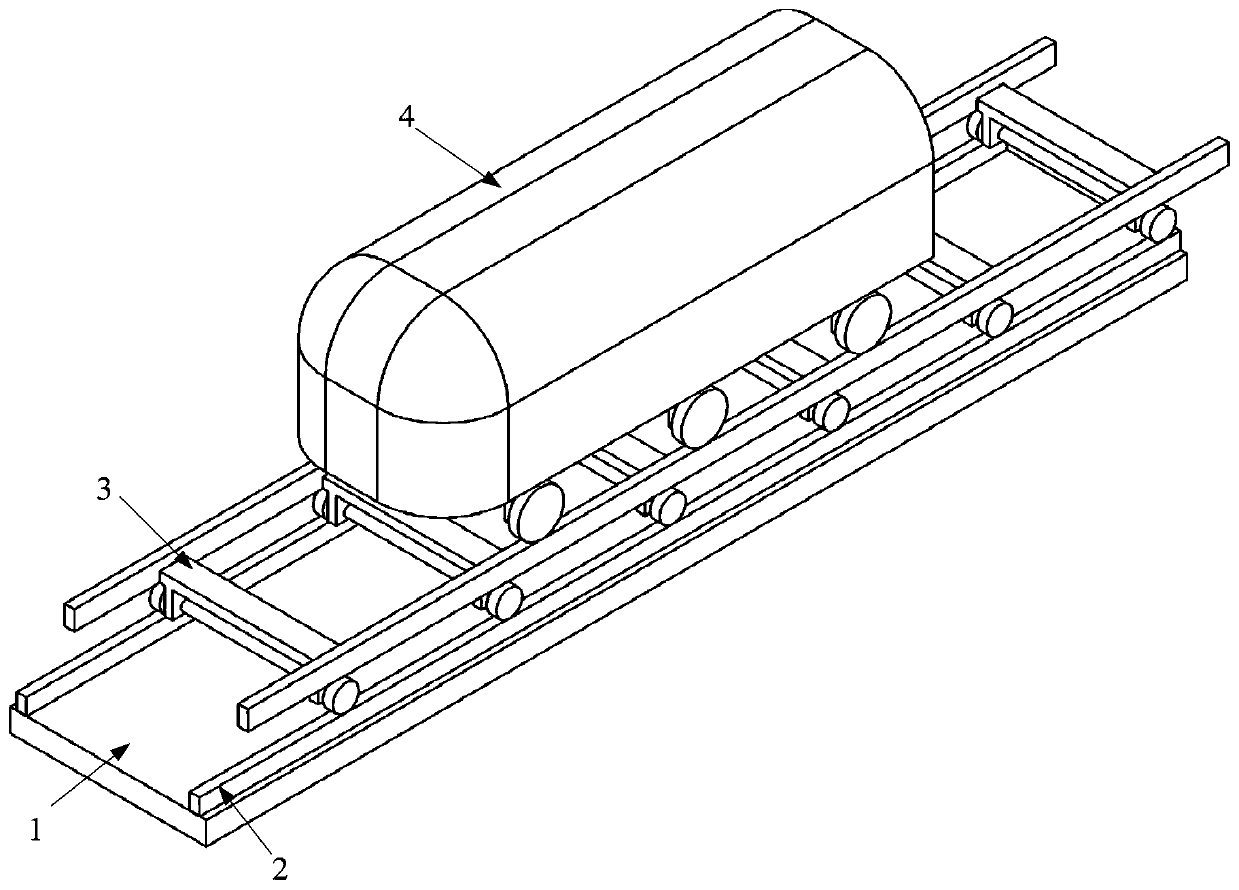

[0036] A two-stage rail-rail high-speed rail transportation system, the core of which is to use two-stage relative motion rails to realize ultra-high-speed rail. figure 1 A schematic diagram of an embodiment of a dual-stage hyperloop is presented. The whole system is divided into three parts: static track (referred to as "static track 2"), high-speed moving track system (referred to as "moving track system") and high-speed train 4. Static track-moving track-train constitutes a two-stage system;

[0037] The static rail 2 is fixedly installed on the subgrade 1 and arranged in a ring shape (the existing high-speed rail track can be directly used);

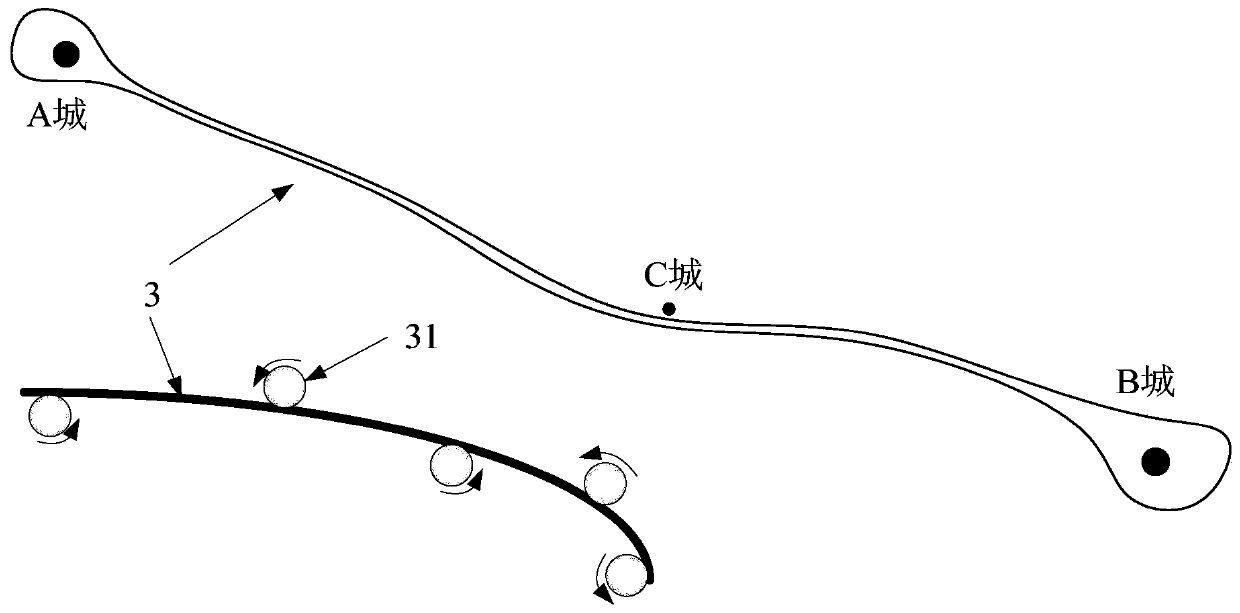

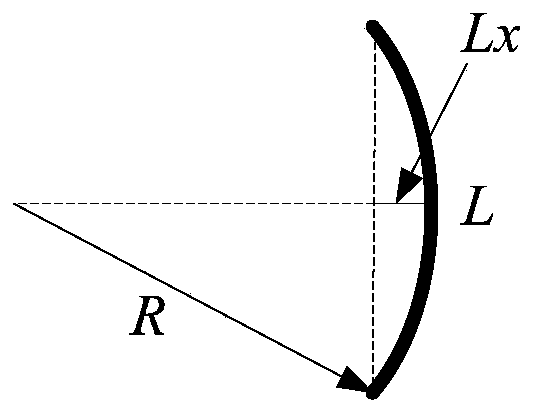

[0038] The moving rail mechanism (i.e. the aforementioned moving rail system) includes a deformable moving rail 3, a drive part and a control unit (see the control system of the moving rail); the moving rail 3 is annular, and can be Moving cyclically on the static rail 2, the control unit causes the moving rail 3 to deform to achiev...

Embodiment 2

[0069]As a specific implementation of the docking device in Embodiment 1, the docking device includes:

[0070] The stop rail 8, comprising a rising section and a horizontal section, is arranged on the outside of the moving rail 3, and the rising section gradually rises to the height of the horizontal section along the moving direction of the moving rail 3, for the train 4 to platform stop;

[0071] The train 4 includes an underframe, and the underframe includes a traveling wheel pair and a parking wheel pair; the traveling wheel pair cooperates with the moving rail 3 , and the parking wheel pair cooperates with the parking rail 8 . see Figure 10a , 10b , 10c;

[0072] see Figure 11-12 , Figure 13a , Figure 13b , when running normally, the wheels of the train 4 cooperate with the moving rail 3. During the parking process, when running to the position where it intersects with the stop rail 8, the first stop wheel pair cooperates with the horizontal section of the stop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com