System for co-processing household garbage and sludge in cement kiln

A domestic waste and co-processing technology, applied in dehydration/drying/thickened sludge treatment, combustion methods, lighting and heating equipment, etc., can solve the problems of large volume and inability to adapt to domestic land demand, so as to save construction and operation costs , social benefits and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

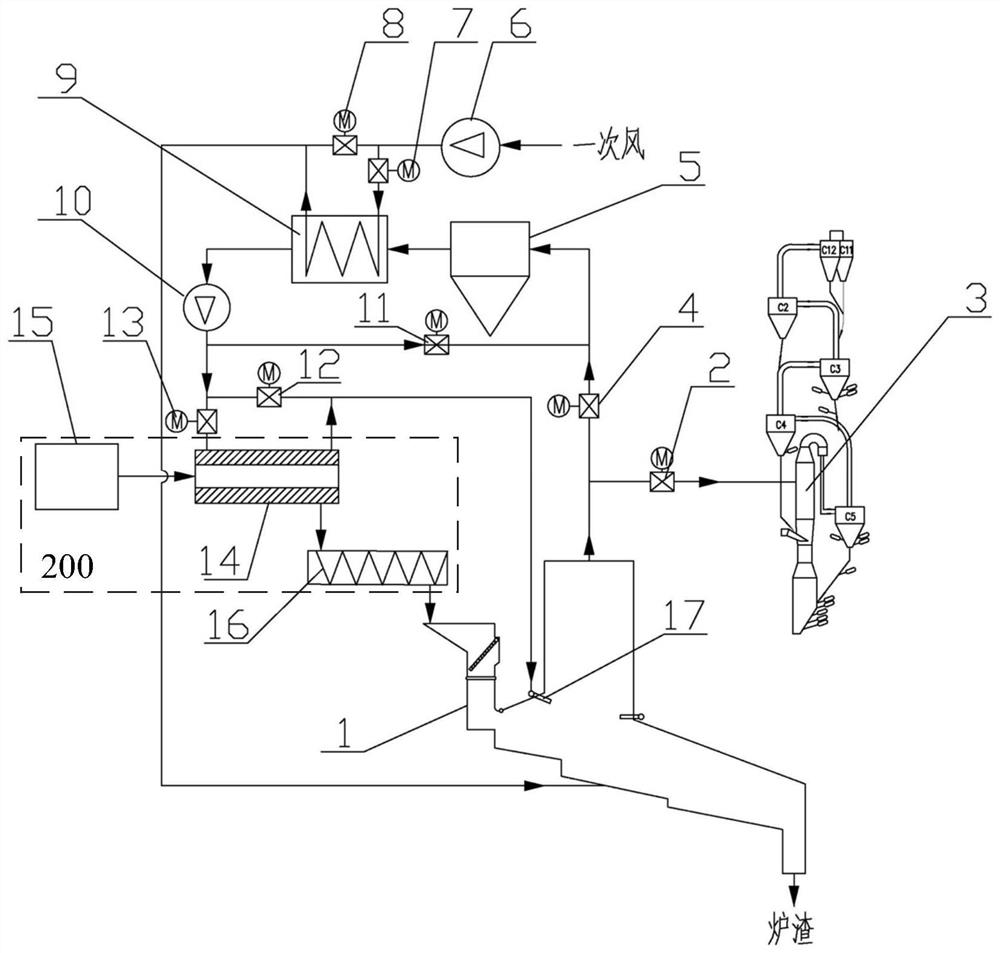

[0077] figure 1 Shown is a schematic diagram of the composition of a better cement kiln co-processing domestic waste and dried sludge system. This system includes the following components.

[0078] Waste incineration unit.

[0079] It is mainly composed of a garbage incinerator 1. The furnace outlet of the garbage incinerator 1 includes a main flue and a furnace flue, and the incinerated slag is used as a cement raw material.

[0080] The garbage incinerator 1 is used for synergistically incinerating dried sludge and domestic garbage. The high-temperature flue gas after the incineration enters the main flue and the exhaust flue through the furnace outlet respectively, and passes through the flue gas respectively arranged on the two flues. The main flue control switch 2 and the furnace flue control switch 4 realize the control of the amount of smoke entering the high-temperature flue. Decomposition unit.

[0081] The decomposition unit is composed of a cement decomposition ...

Embodiment 2

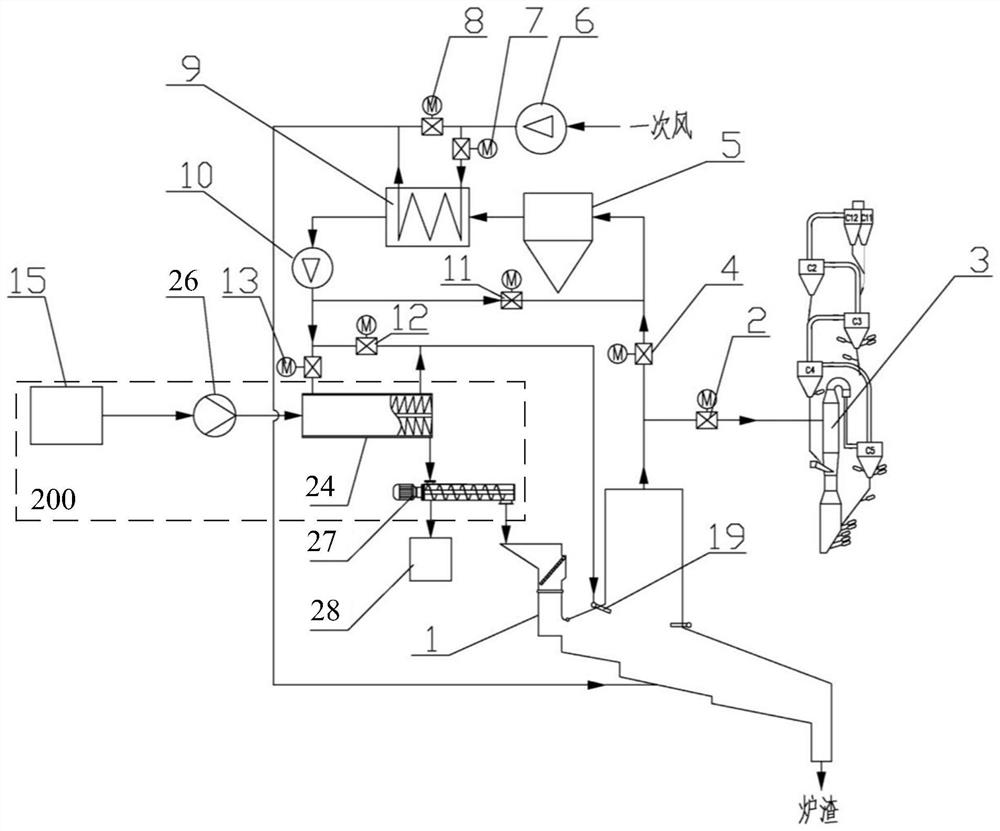

[0107] figure 2 The shown embodiment 2 of this case also includes a waste incineration unit, a decomposition unit, and a flue gas recirculation unit. It is different from embodiment 1 in that the sludge treatment unit 200 uses a sludge low-temperature carbonization unit.

[0108] Specifically, the sludge low-temperature carbonization unit includes a wet sludge storage bin 15, a pressurized pump 26, a sludge carbonization machine 24, and a sludge dehydrator 27, wherein the wet sludge storage bin 15 is connected to the sludge storage bin 15 through a pressurized pump 26. The inlet of the peatization machine 24 and the outlet of the sludge carbonization machine 24 are connected to a sludge dehydrator 27 , and the dehydrated sludge is sent into the garbage incinerator 1 .

[0109] In order to cooperate with the waste water generated after sludge dehydration, this embodiment also adopts a waste water treatment unit 28 .

[0110] Furthermore, the sludge carbonization machine 24 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com