Overturning feeding device for semiconductor encapsulation bonding equipment

A semiconductor and pusher technology, applied in conveyor control devices, transportation and packaging, conveyors, etc., can solve problems such as deformation of the frame base island and scratches on the surface of the frame base island, so as to improve profits and reduce hidden dangers in quality. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

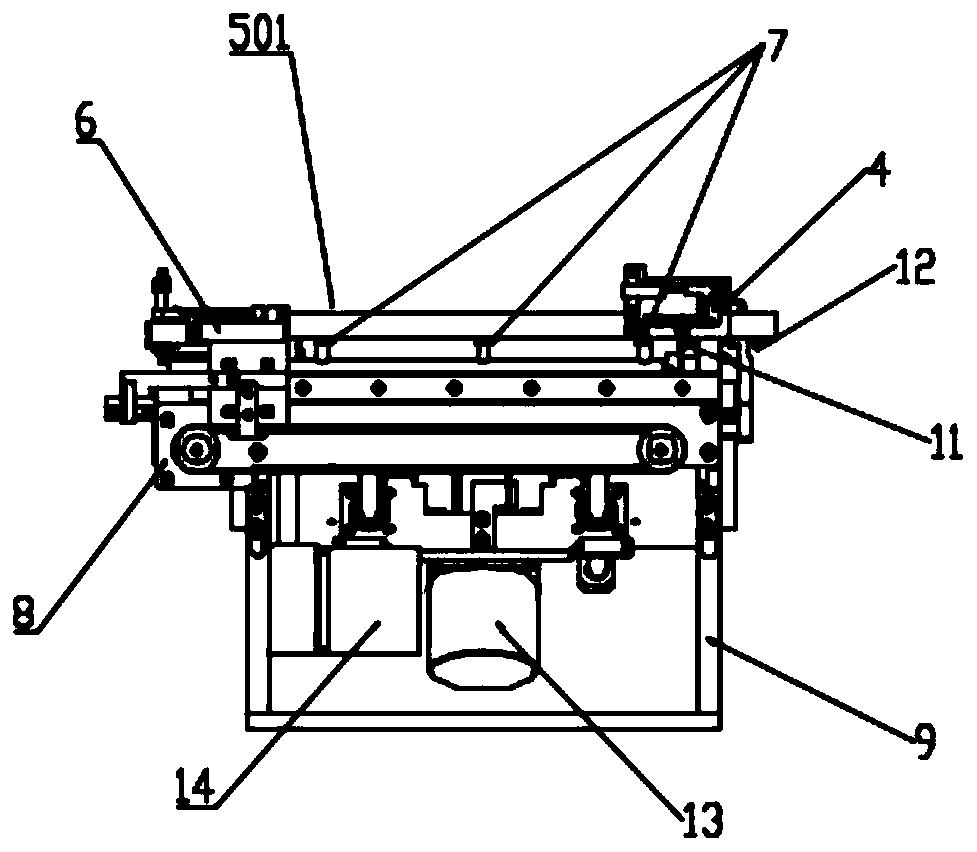

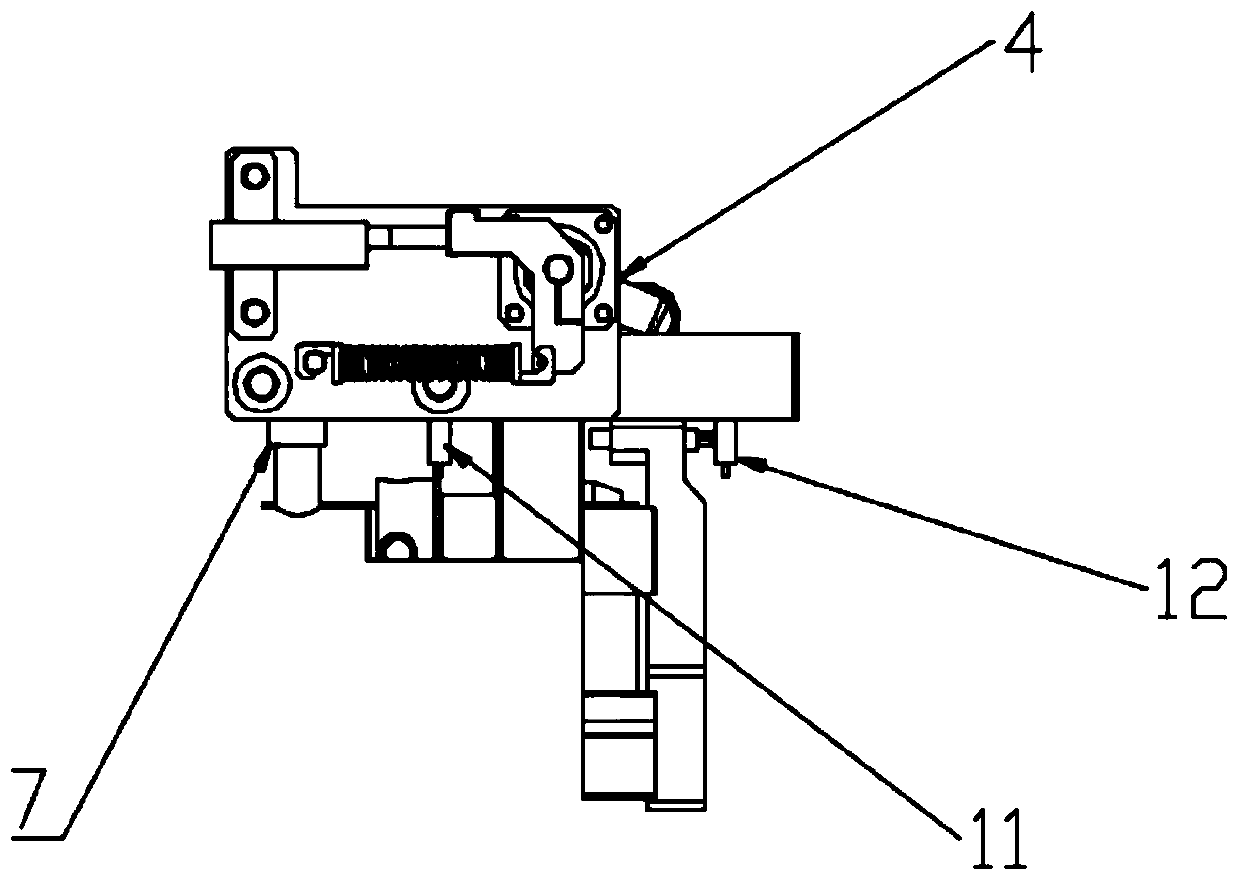

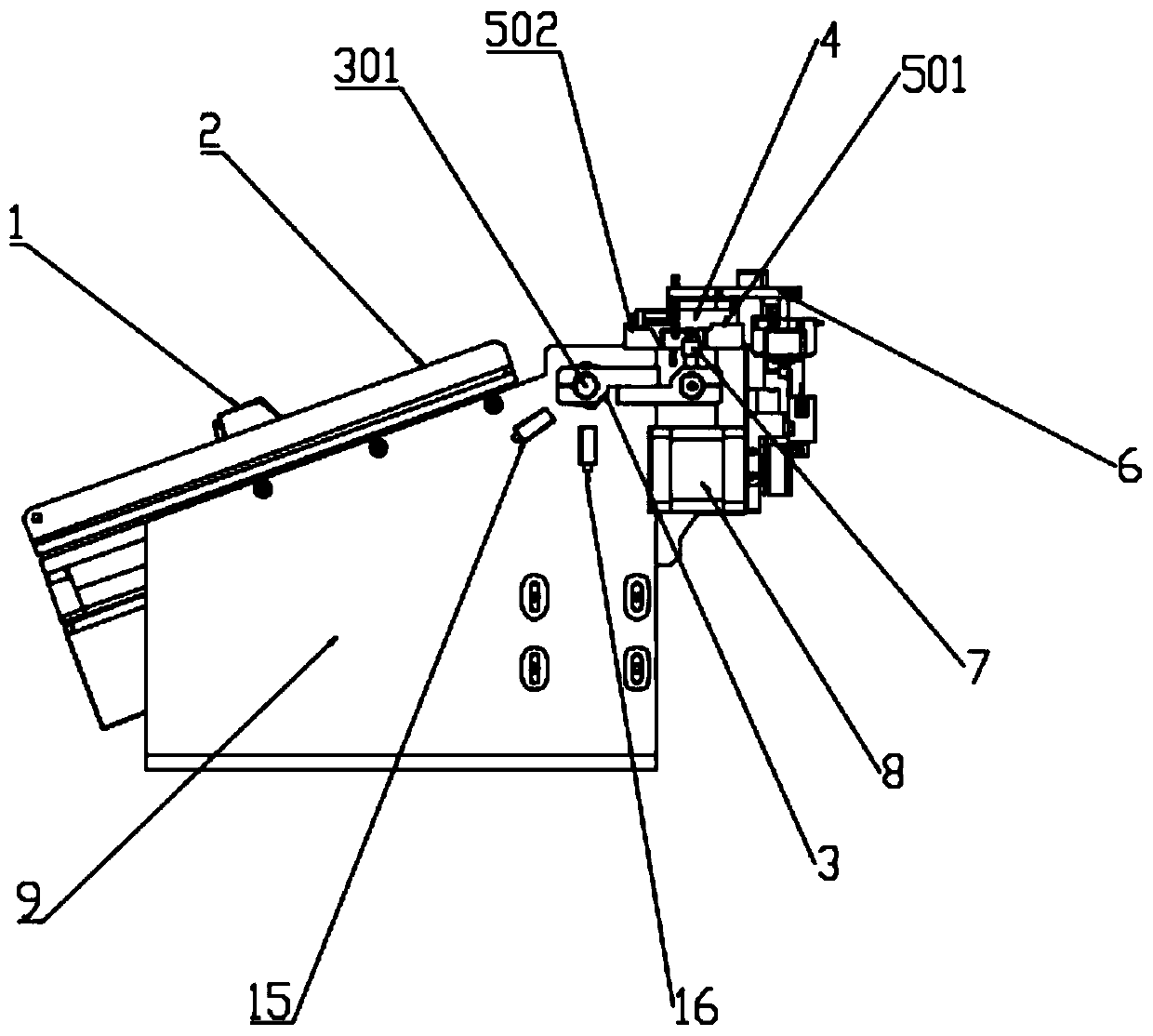

[0044] Such as Figure 1A , Figure 2A , image 3 , Figure 4A , Figure 5 , Figure 6A and combine Figure 1B , Figure 2B , Figure 4B , Figure 6B As shown, a flipping and feeding device for semiconductor packaging die bonding equipment includes the following devices or components:

[0045] (1) turning over feeding device mount 9, turning over feeding device mount 9 comprises base plate and being vertically connected with base plate and two side plates symmetrically arranged on the left and right sides of base plate, the top front end of turning over feeding device mount 9 ( That is, the top front ends of the two side plates) are parallel to the ground, and the main body after the top front end of the overturning feeding device seat frame 9 is inclined downward, and the inclination angle is 30 degrees (that is, the angle between the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com