Method for visually evaluating quality of electrotinning solution on line

A technology of electroplating tin and solution, applied in the direction of electrical program control, program control, instruments, etc., can solve the problems of complex device manufacturing, inability to detect, difficult online detection system, etc., to reduce hidden quality problems and avoid the effect of hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to clearly illustrate the solution of the present invention, the present invention will be further described below in conjunction with specific examples.

[0029] The present invention provides a method for visually evaluating the quality of electroplating tin solution on-line. The method includes the following steps:

[0030] (1) On-line sampling: obtain the electroplating solution in a transparent container in real time from the running tank of the electroplating unit;

[0031] (2) Data acquisition: move the transparent container containing the electroplating solution to the camera detection area, and collect the online solution color parameters of the pixels in the detection area;

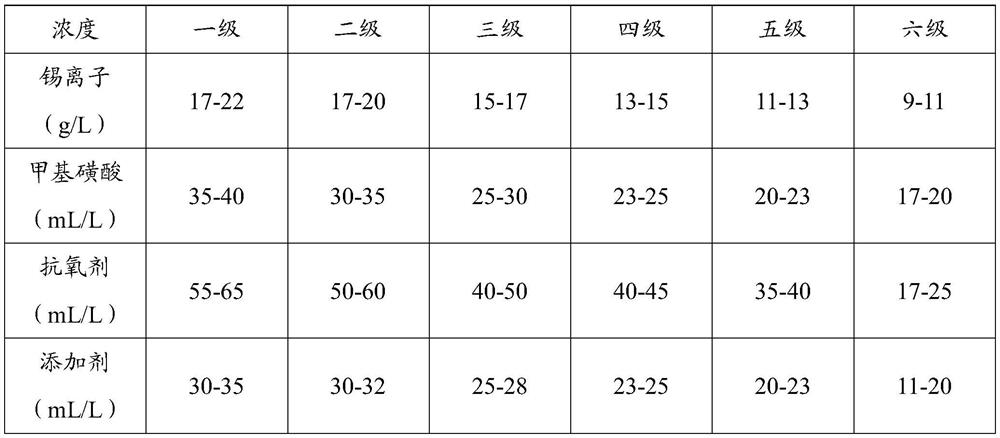

[0032] (3) Evaluation and grading: compare the online solution color parameters with the grading solution color parameters, determine the grading corresponding to the best grading solution color parameters matching with the online solution color parameters, thereby determining th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com