Construction method of subway station continuous wall

A technology for subway stations and construction methods, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve problems such as endangering the safety of buildings and underground pipelines, land subsidence, collapse, and unfavorable tank wall stability, and achieves guaranteeing the construction progress. Strong bearing capacity and the effect of reducing hidden dangers of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

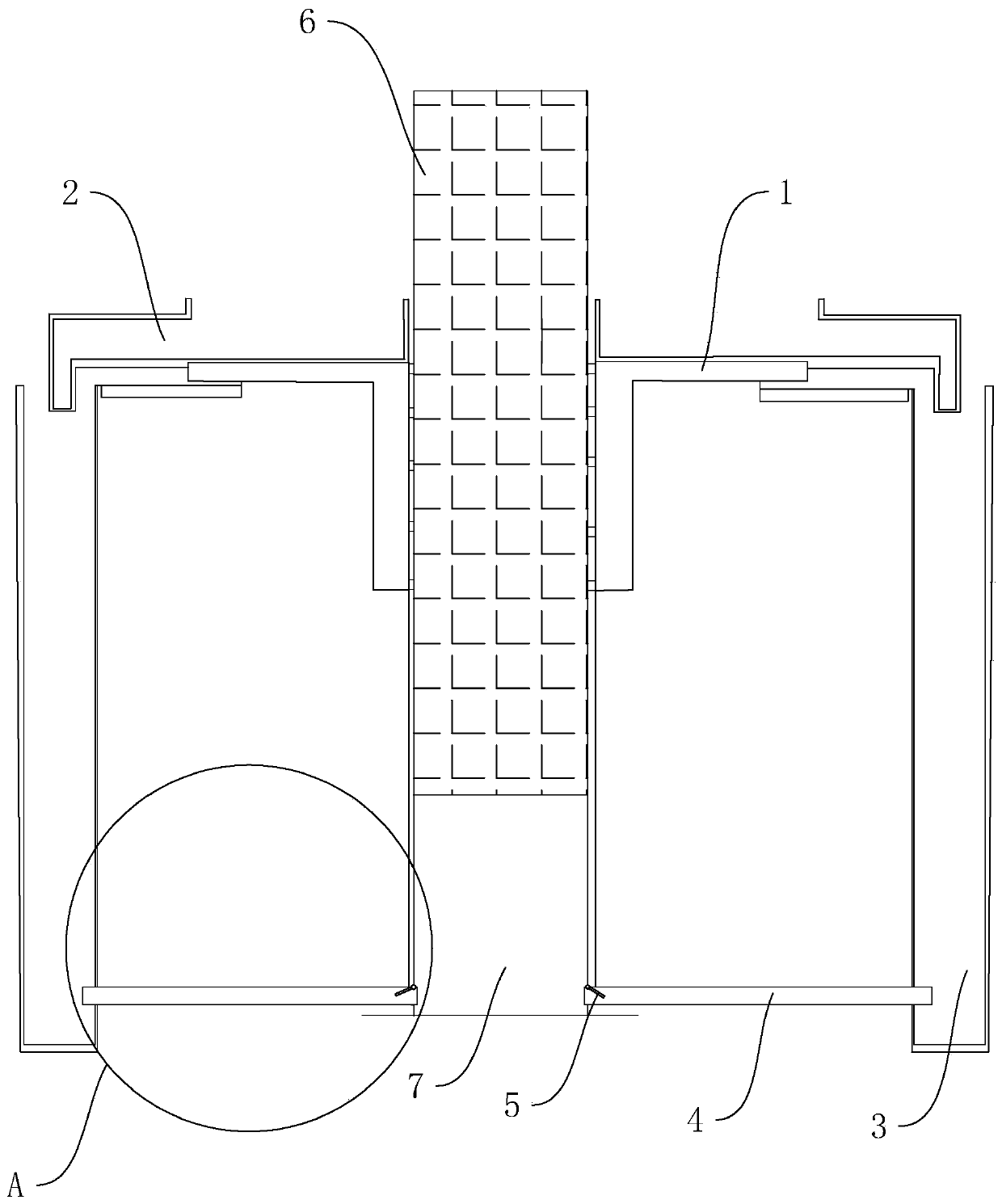

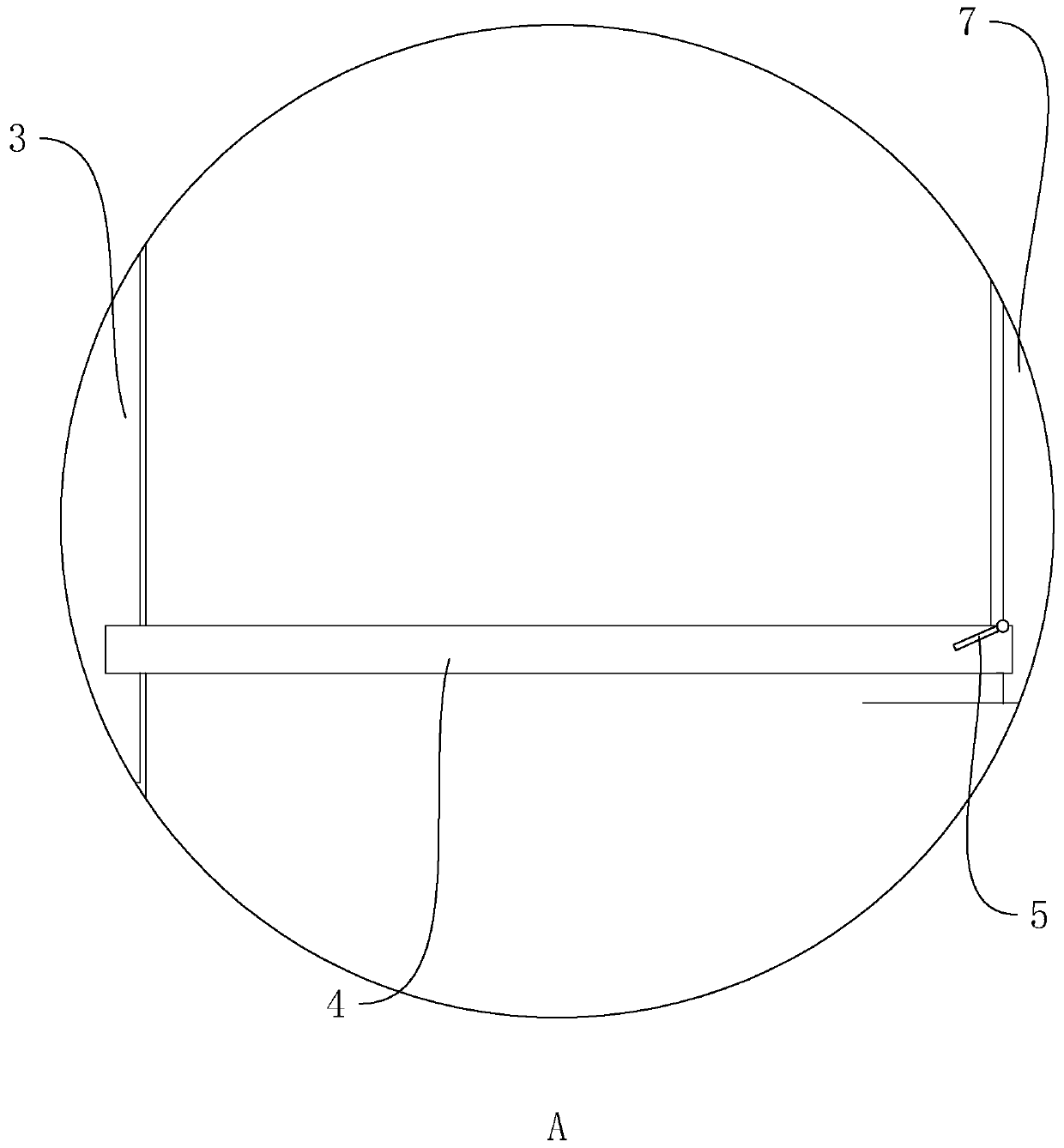

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

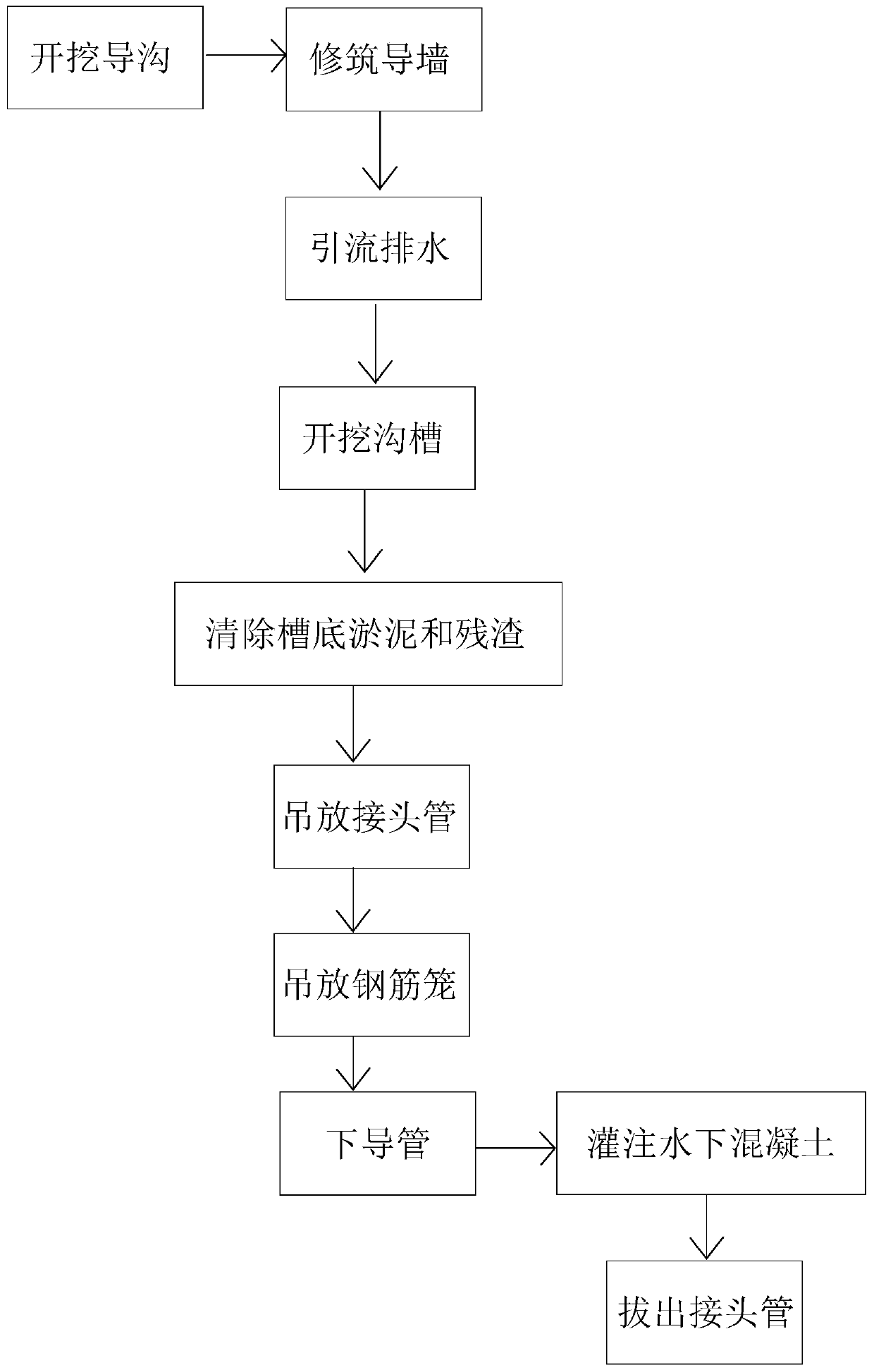

[0043] refer to figure 1 , is the construction method of a kind of subway station diaphragm wall disclosed by the present invention, comprises the following steps:

[0044] 1) Excavation of guide ditch: Level the site, put in the control points of each main axis according to the closed wire and reference point around the foundation pit, use a total station to measure and position, measure and position each axis, and then close the periphery of the foundation pit The conductors, reference points, and control points are measured and calibrated multiple times until the error value is within the preset range, and then the guide trench is excavated and the spoil is disposed of.

[0045] Level the site to remove obstacles and keep the excavation surface flat, which is beneficial for measuring and positioning the position of the guide wall 1 .

[0046] 2) Build gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com