Construction method of horizontal construction joint stagnant water steel plate not penetrating stirrups at buttress column

A technology of horizontal construction joints and water-stop steel plates, applied in water conservancy projects, underwater structures, artificial islands, etc., can solve problems such as structural safety hazards, leakage, disconnection, etc., to improve technical management capabilities and save construction costs , Improve the effect of corporate image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the invention, and are not intended to limit the scope of the present invention.

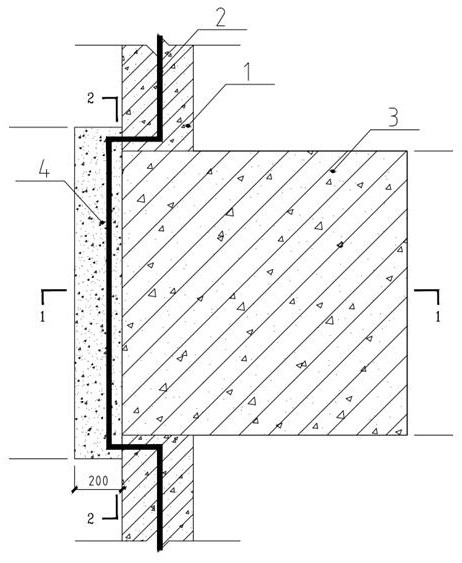

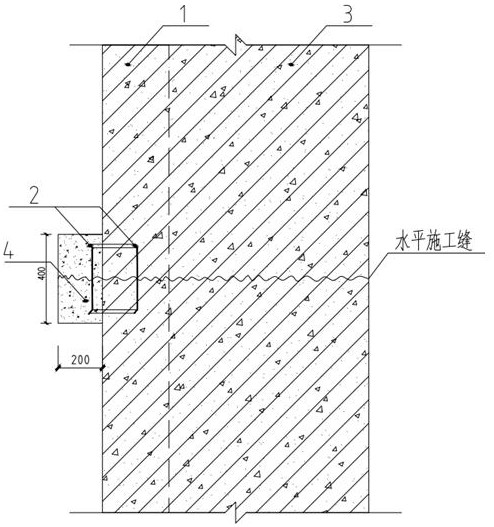

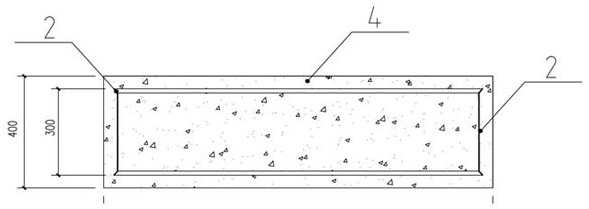

[0020] Such as figure 1 As shown, the construction method of the horizontal construction joint waterproof steel plate at the buttress column of the present invention does not penetrate the stirrup, by setting the outer side of the buttress column 3 connected with the basement exterior wall 1 for the installation of the horizontal construction joint waterproof steel plate 2 The conversion channel structure column lug 4, the waterproof steel plate 2 is pre-embedded and installed during the construction, the water-stop steel plate 2 is directly bypassed and installed between the column lugs 4 beside the buttress column 3, and then converted back to the original after passing the buttress column 3 In the horizontal construction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com