Manufacturing method of triacetate interwoven fabric

A production method, the technology of triacetic acid, is applied in textiles, fabrics, textiles and papermaking, etc. It can solve the problems of poor experience and achieve scientific and reasonable technology, high safety, and soft luster.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

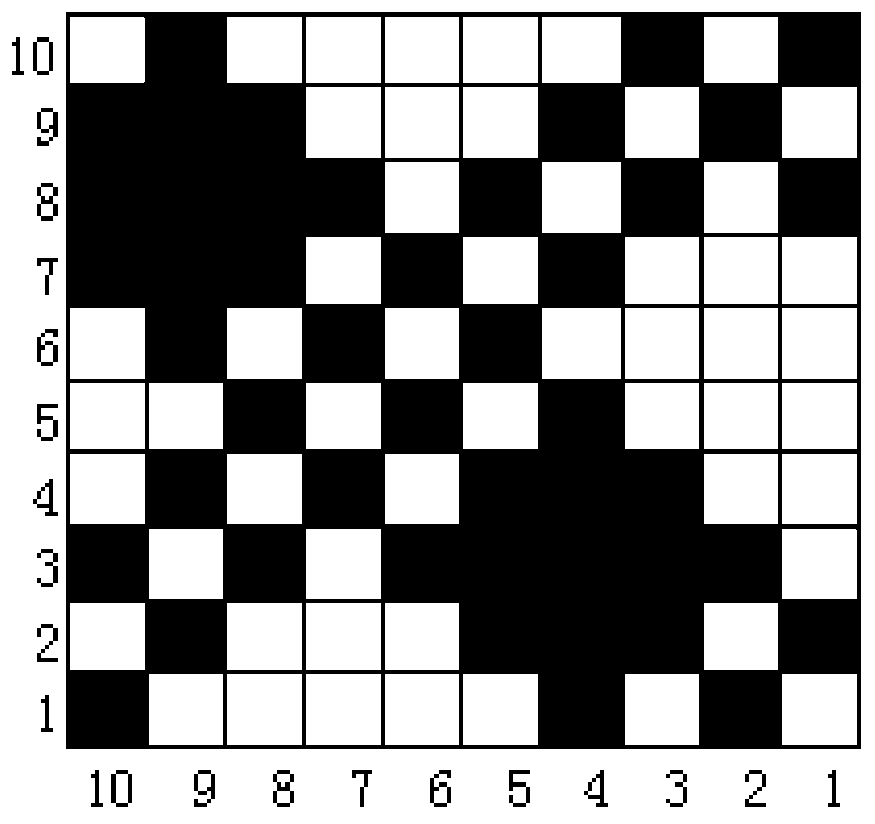

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] A kind of preparation method of triacetate interwoven fabric, described preparation method comprises the steps:

[0019] ①. Take triacetate filament and modal fiber and form a blended yarn according to 45:55, which is used as the warp yarn of the fabric for standby; the blended yarn is 40s / 1, and its twist is 700 twists, and the twist direction is S direction. Optionally, the matte POY and matte SSY used in step ② have a fineness of 50D and 100D respectively.

[0020] ②. Take the matte POY and matte SSY as the weft raw materials of the fabric for standby;

[0021] ③. Put the blended yarn formed in step ① in the moisturizing room to keep moisture. The temperature of the blended yarn in the moisturizing room is 25°C, the humidity is 75%, and the moisturizing time is 12 hours; moisturizing can make the blended yarn balance its ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com