Maintenance equipment for double-block ballastless track bed slab

A ballastless track and track bed slab technology, applied in track maintenance, track, track laying, etc., can solve the problems of high labor intensity of maintenance workers, uneven maintenance quality, and large labor force, so as to achieve good humidity control and improve construction efficiency. High quality, highly automated results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

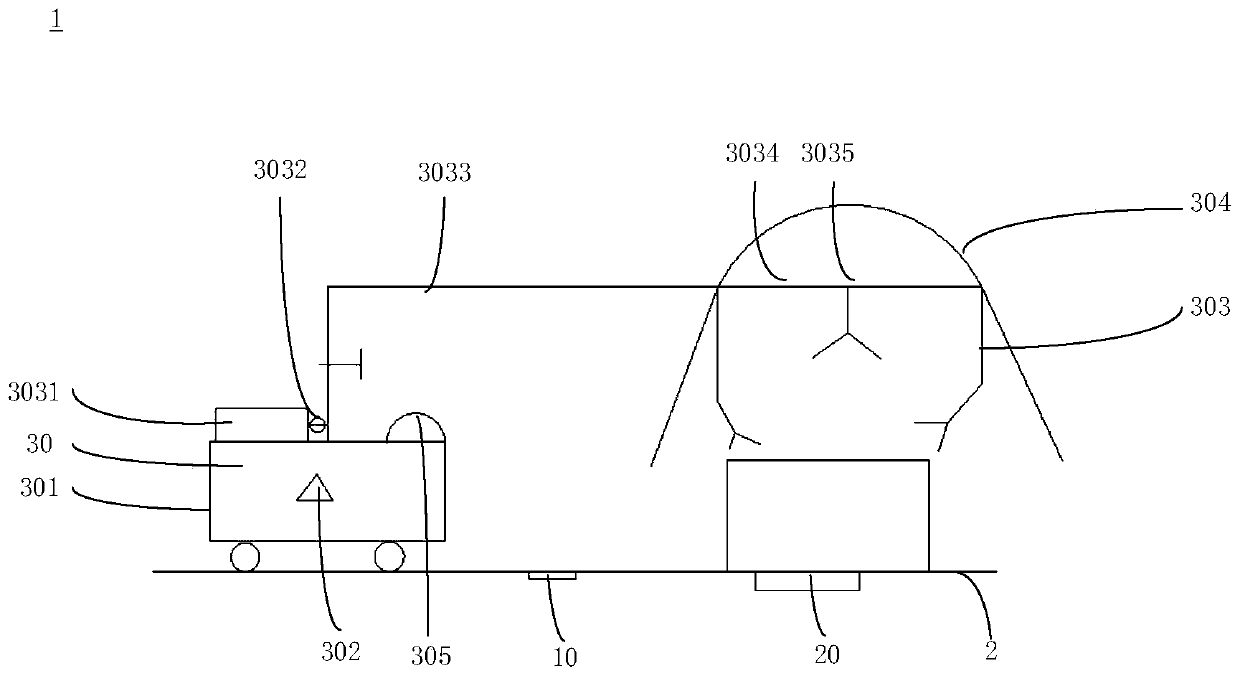

[0034] The specific steps for the construction of the maintenance equipment 11 for the double-block ballastless track 1 bed slab are:

[0035] S11: Laying of geotextiles and construction stakeout. Specifically, the following steps are included:

[0036]Before the construction of the track bed slab, reasonable tooling and equipment shall be provided according to the construction organization, and the equipment and equipment such as rail bent frame, steel formwork gantry crane, truck crane, water truck, pump truck, sleeper-dividing platform, rainproof shed and fine-tuning instrument are complete. When the track bent frame is equipped, it should be reasonably equipped according to the design form of the track bed slab, and special attention should be paid to the design size of the track bed slab with special structures such as continuous beams and abutments.

[0037] S12: Bottom reinforcement installation: use insulating coated reinforcement, place longitudinal reinforcement fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com