Lifting and drilling integrated machine

An all-in-one machine and drilling mechanism technology, which is applied to cranes, earthwork drilling, drilling equipment, etc., can solve problems such as low hoisting efficiency, increased mechanical shifts, and inconvenient mechanical transitions, so as to improve safety and work efficiency. The effect of reducing installation space and reducing manual participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

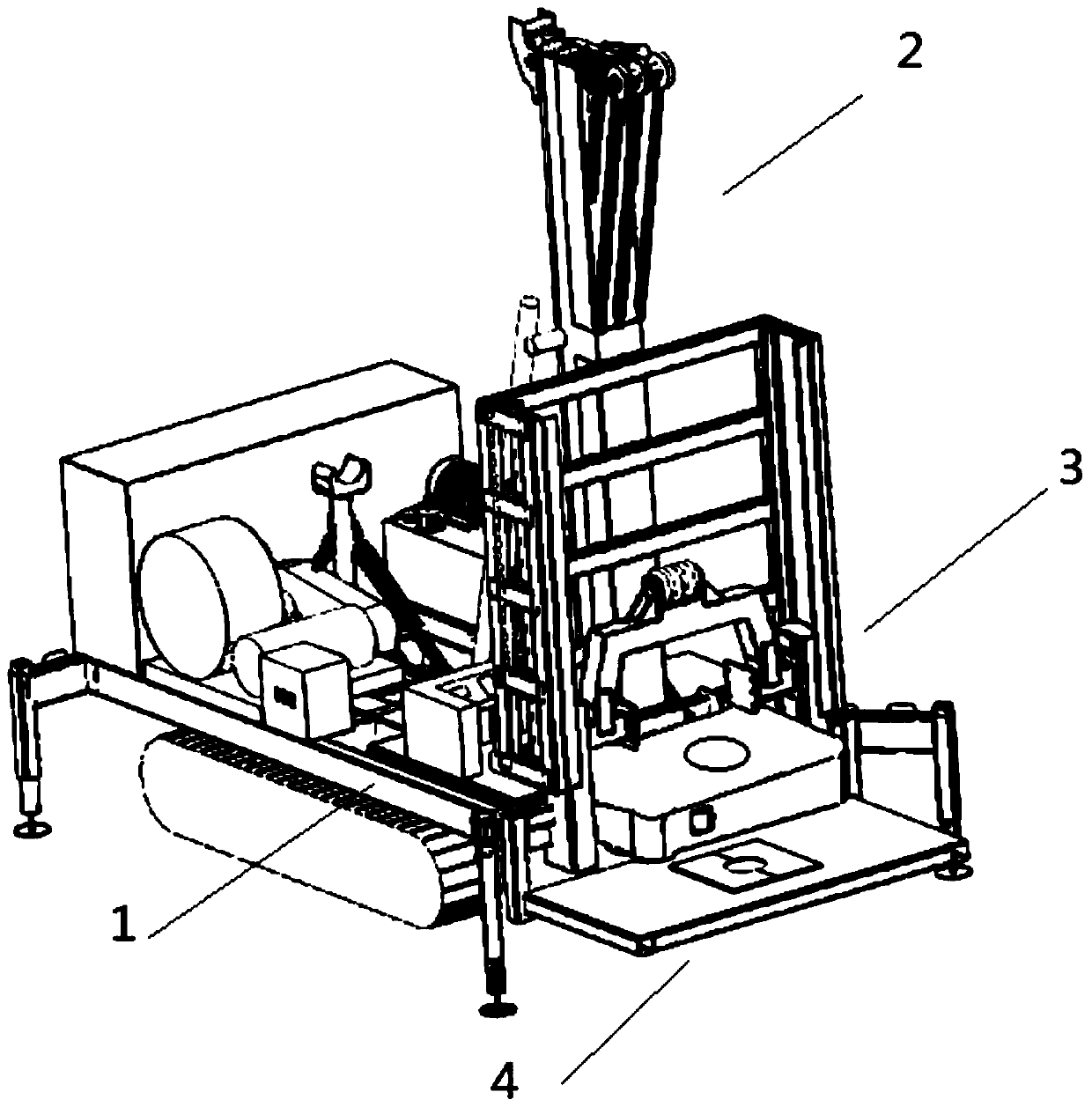

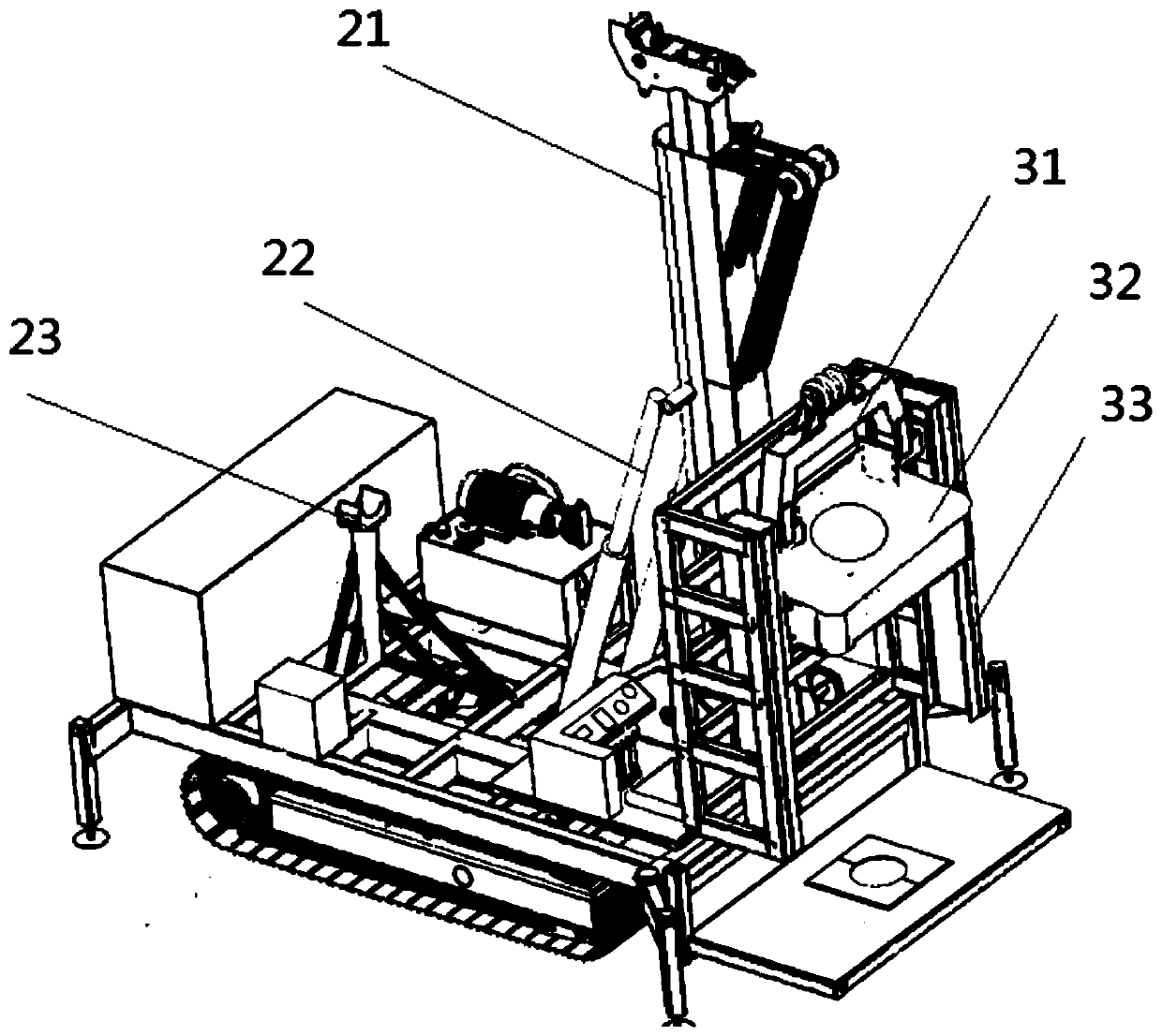

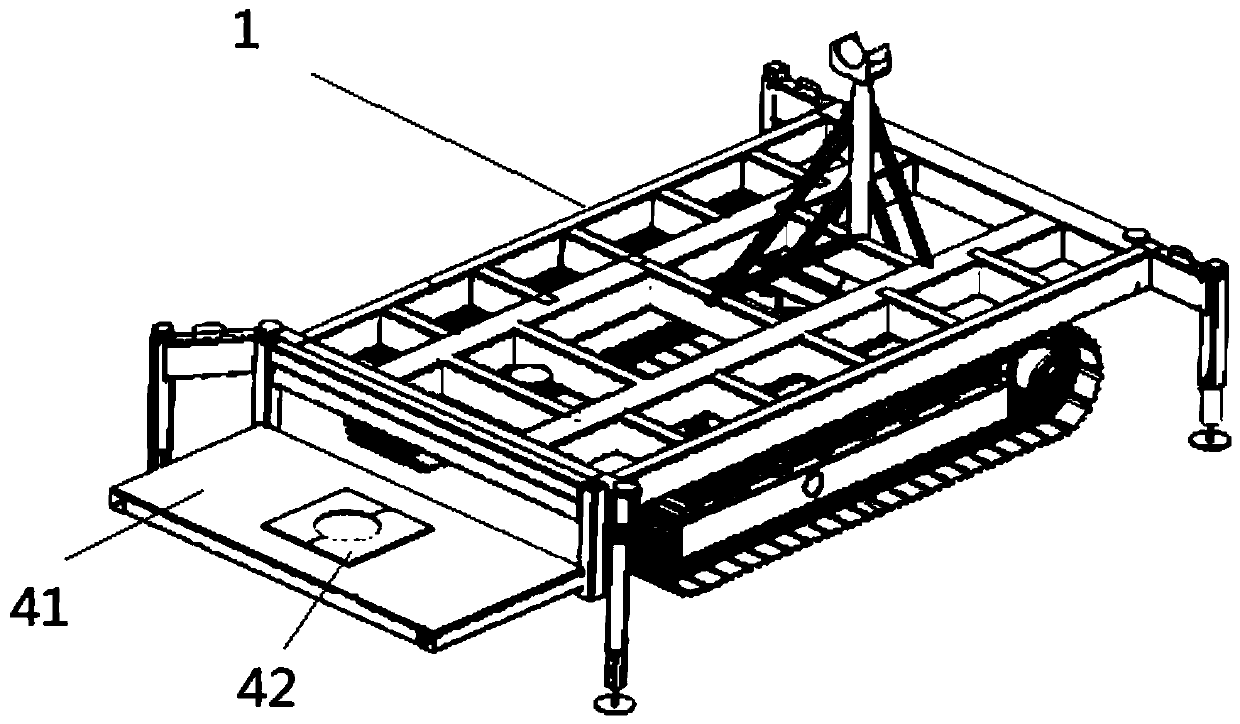

[0019] In order to make the purpose, technical solutions and advantages of the present invention clearer, the following in conjunction with specific examples, and with reference to the appended Figure 1-4 , to further describe the present invention in detail.

[0020] In one embodiment of the present invention, the integrated hanging and drilling machine includes: an underframe 1 , a lifting mechanism 2 , a drilling mechanism 3 , a wellhead plate mechanism 4 , and a slewing mechanism.

[0021] Underframe 1 is used as the skeleton of the whole machine, and is used for installing all assemblies and components, so that the whole machine becomes a whole.

[0022] In one embodiment, the crane-drilling machine includes a walking device, which is used to support the body, and convert the driving torque and rotational motion transmitted from the engine to the driving wheels into the driving force and forward and backward motion required for the work and travel of the tracked vehicle....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com