High-level parallel drilling gas extraction method in swelling rock strata

A technology of gas drainage and rock formation, which is applied in the field of coal mine gas drainage to achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

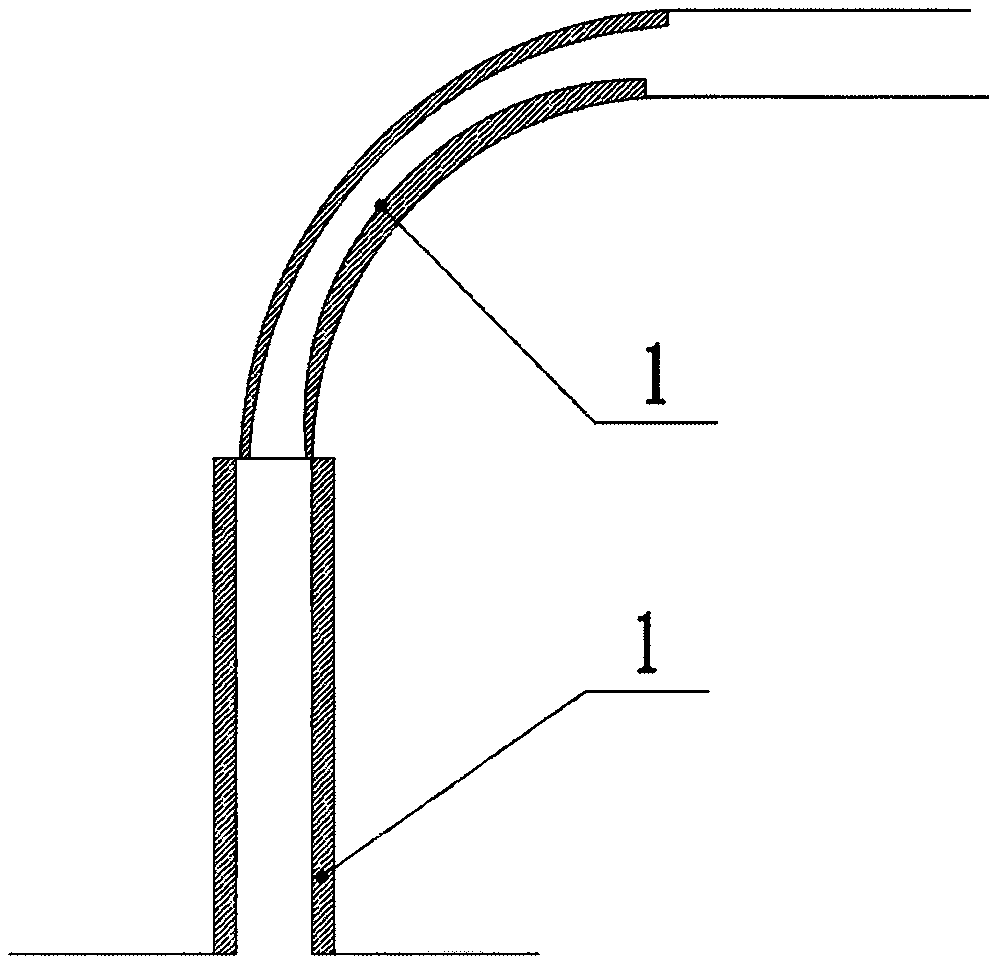

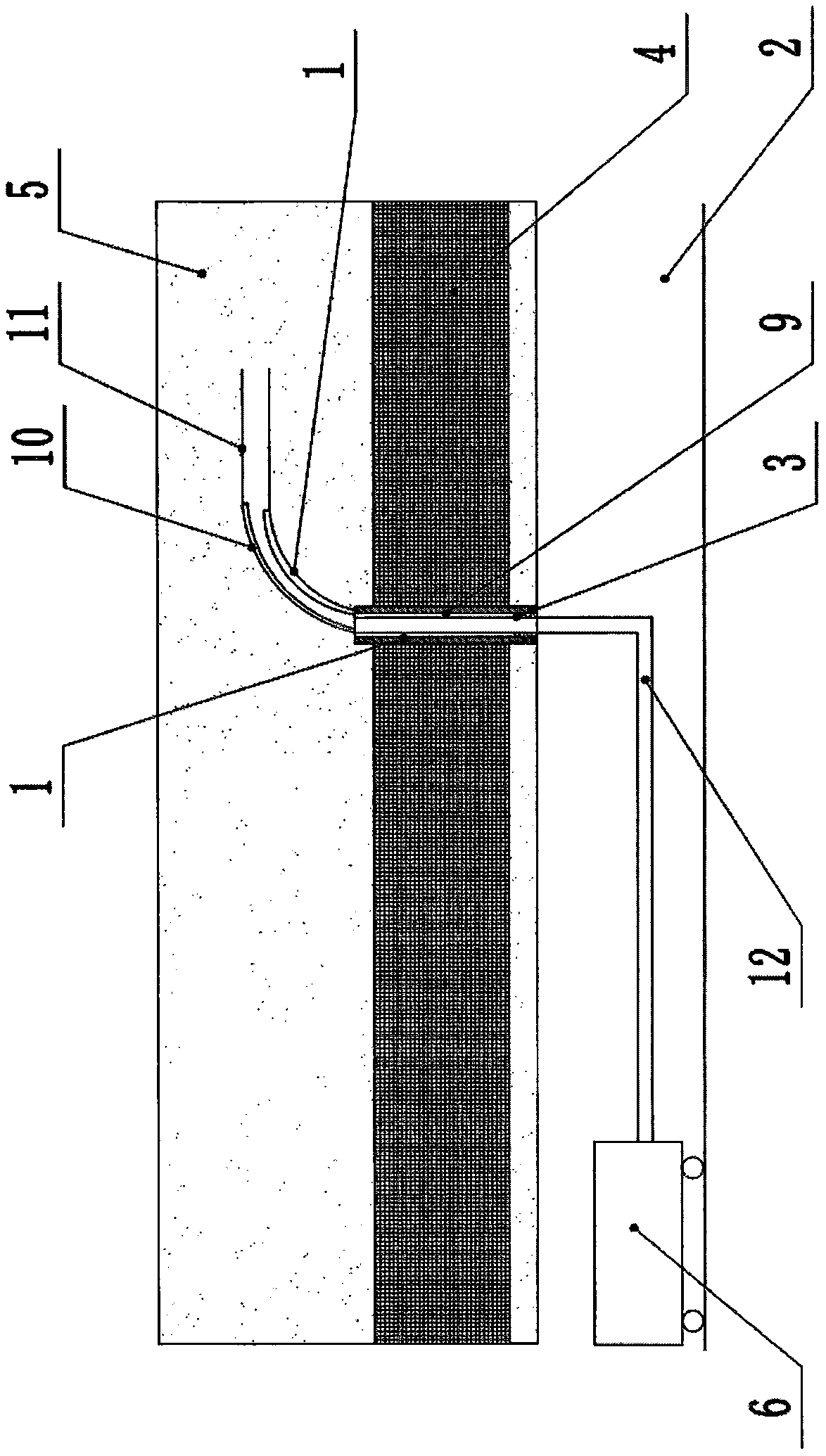

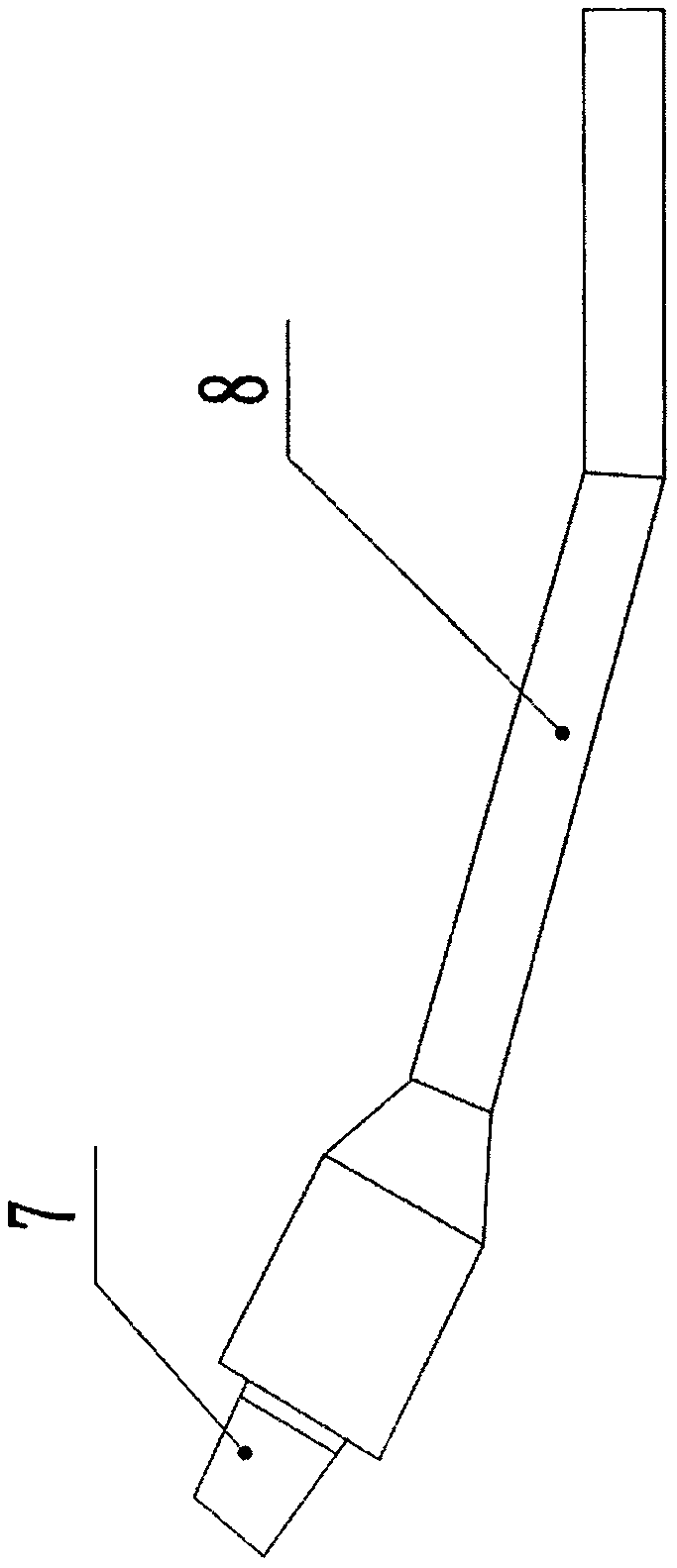

[0032] Refer to the attached Figure 1-3 And embodiment the present invention is described in detail:

[0033] Such as Figure 1-3 As shown, a kind of expansive rock formation high level parallel borehole gas drainage method of the present invention comprises the following steps:

[0034] Step 1: Arranging a drilling site in the air return roadway 2, using a drilling rig to drill holes vertically to the roof of the coal seam.

[0035] Step 2, when the drilling rig reaches the expansive rock formation 4 , drill vertically upwards and pass through the expansive rock formation 4 .

[0036] Step 3: After the drilling rig drills through the expansive rock formation 4 , the drilled hole is reamed to form the first hole segment 9 .

[0037] Step 4: Carry out casing operation on the first hole section 9 and fix the pipe with cement slurry.

[0038] Step five, continue drilling along the first hole section 9 with the deflection drilling tool to form a second hole section 10 with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com